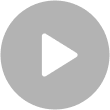

In the field of stationary asphalt mixing plants, batch and drum type are the two mainstream technology routes, and there are significant differences between the two in terms of process principle, plant structure, production characteristics, applicable scenarios and long-term economics. There are significant differences between the two in terms of process principles, plant structure, production characteristics, application scenarios and long-term economics. Understanding these differences will help project decision makers to make the best choice to meet the actual needs.

Batch-type

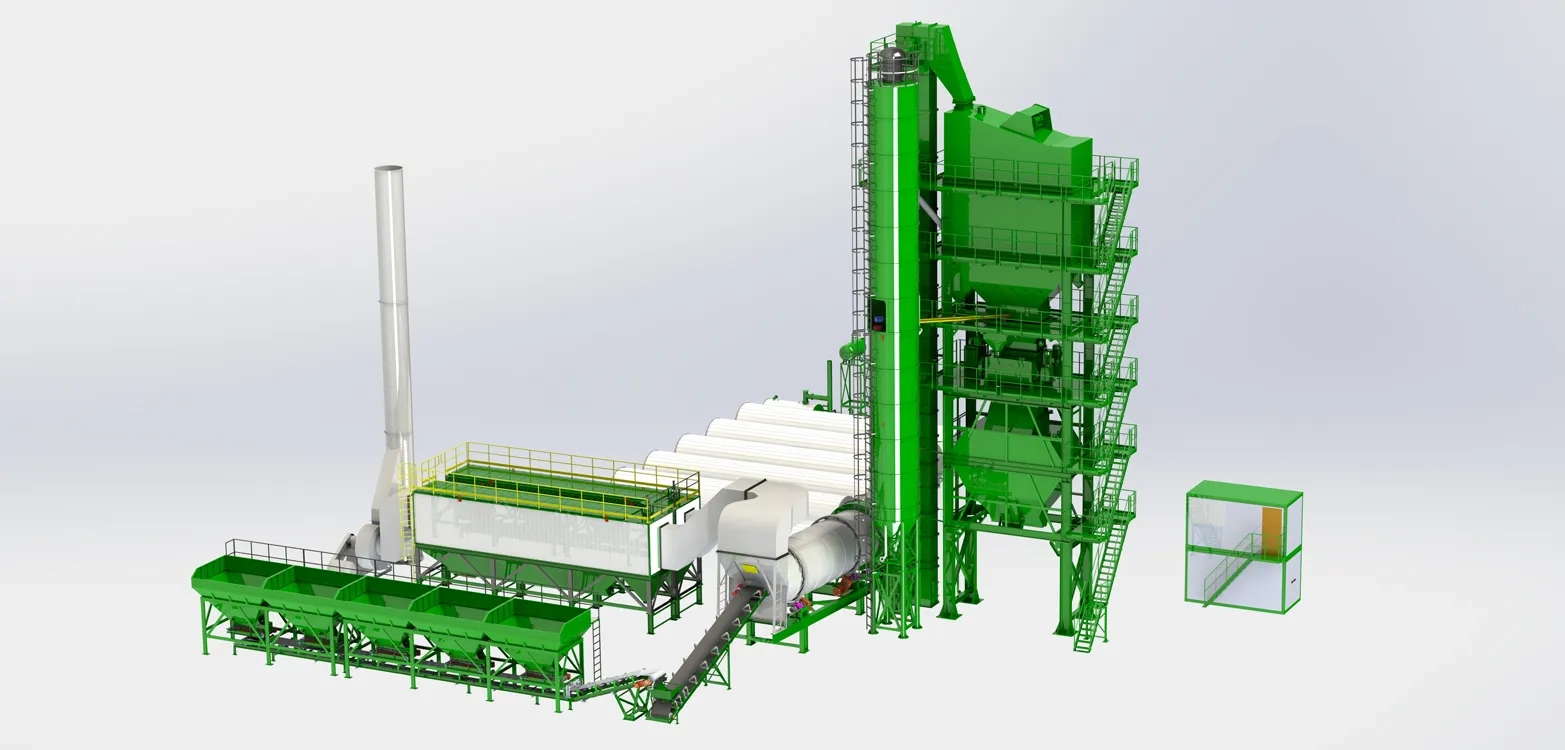

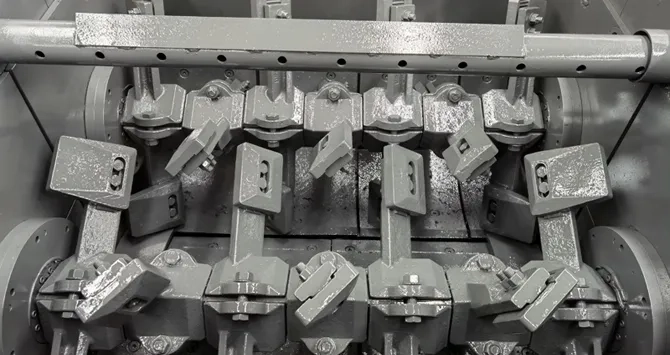

Core process characteristics: production is based on “batches”, each batch is weighed, fed, mixed and discharged independently, with a cycle time of 40-50 seconds (depending on the model and recipe). The whole cycle is usually controlled in 40-50 seconds (depending on the model and formula). Aggregates are first dried, lifted, screened by secondary vibration and deposited into a hot silo, and then fed into the mixer batch by batch for forced mixing according to a precise ratio. This process path of “first classify, then measure, then mix” ensures high proportioning accuracy and mixing uniformity.

Main advantages

- Extremely high mixing uniformity (up to 99% or more), with a better coating of the asphalt by the aggregate, reducing the risk of segregation.

- Strong flexibility in proportioning: the grading, oil/stone ratio and modifier dosage can be adjusted at any time, which is suitable for the production of a variety of formulas (e.g. AC-13, SMA-13, OGFC, colored asphalt, warm mix asphalt, etc.).

- Fine quality control: each batch is independently measured and recorded, supporting complete quality traceability, meeting the acceptance requirements of high standard projects such as highways and airports.

- Temperature control is more accurate: hot aggregate is stored in separate bins to reduce the temperature gradient, and the temperature fluctuation of the discharged material is small (within ±5℃).

- The mixing proportion of recycled asphalt (RAP) can be higher (commonly 30%-50%, some configurations up to 70%), which can still maintain the performance of the mixture under high quality control, and is conducive to resource recycling.

Main disadvantages

- The production process has short intervals, energy consumption is slightly higher than the drum type (but through optimization of combustion and insulation design has significantly reduced the gap).

- Initial investment and floor space are relatively large.

Typical application scenarios: the upper layer of high-grade highways, airport runways, urban expressways, ports, heavy-duty pavement, large-scale modified asphalt production bases, and other projects that require very high quality consistency.

Drum-type

Core process characteristics: cold aggregate, mineral powder, asphalt in the drum synchronized completion of drying, heating, mixing, the production process is continuous and uninterrupted. The ratio is adjusted in real time by flow meter and proportional valve, and the asphalt is directly sprayed into the middle of the drum to mix with the hot aggregate.

Main Advantages

- Continuous production, high equipment utilization, more stable daily output.

- Relatively simple structure with low total plant weight and footprint.

- Initial acquisition costs are typically lower than intermittent types of the same capacity.

- Relatively low energy and labor costs in stable production of a single recipe.

Major Disadvantages

- Slow response to ratio adjustments and inability to quickly switch between multiple formulations.

- Mixing uniformity is slightly inferior to batch type (especially the effect of fines coating and modifier dispersion).

- Difficult to control temperature, easy to appear local overheating or underheating phenomenon.

- It is difficult to guarantee the quality stability when high proportion of RAP is mixed.

Typical application scenarios: the lower layer of medium and low-grade highways, rural roads, county and township highways, stabilizing the mass production of single formula projects, or projects that are sensitive to the initial investment and have a short construction period.

Comparison: If the project has high pavement grade, various formulations, strict quality acceptance, large total dosage and long construction period, intermittent type (such as ZOOMLINE ZAP-S series) is highly recommended; if the pursuit of the lowest initial investment, a single formulation of large quantities of continuous production, and quality requirements are relatively lax, the drum type is more cost-effective. At present, most of the world's high-grade pavement projects use batch-type fixed mixing plant.