We believe that answers below will be vital and helpful for you starting your business. You will find quick answers to the most common questions here.

What is the price of an asphalt mixing plant? What are the payment methods?

Asphalt mixing plant prices vary by model, configuration, and capacity. Contact our sales team for the accurate quote.

We accept T/T (Telegraphic Transfer), L/C(Letter of credit), BG (bank guarantee), D/P(Documents against Payment), D/A((Documents against Acceptance), Western Union and other. T/T transfers via installments: 30% advance upon contract signing, 70% before shipment. Terms are negotiable. For more details, share your specific needs.

How long does the asphalt plant take to install the equipment?

The installation time for the equipment is influenced by factors such as the scale of the mixing plant, the conditions of the installation site, and the experience of the installation team. Generally speaking, the installation and commissioning period for a small mobile asphalt mixing plant is approximately 7-10 days; for a medium-sized fixed mixing plant, it takes 15-20 days; and for a large, complex mixing plant system, the installation and commissioning period may extend up to 30-45 days. We will develop a detailed installation plan based on actual conditions and assign a professional team to ensure installation progress and quality.

How many person are needed for the operation of whole asphalt mixing plant?

The number of operate an asphalt mixing plant vary by plant type and automation level:

Small to medium scale asphalt plants (20-150 t/h): 3-6 persons per shift.

Large scale asphalt plants (200+ t/h): 6-8 persons per shift.

(1 Senior Supervisor, 1 Control Room Operators, 3-4 Field Operators, 1 Support Staff)

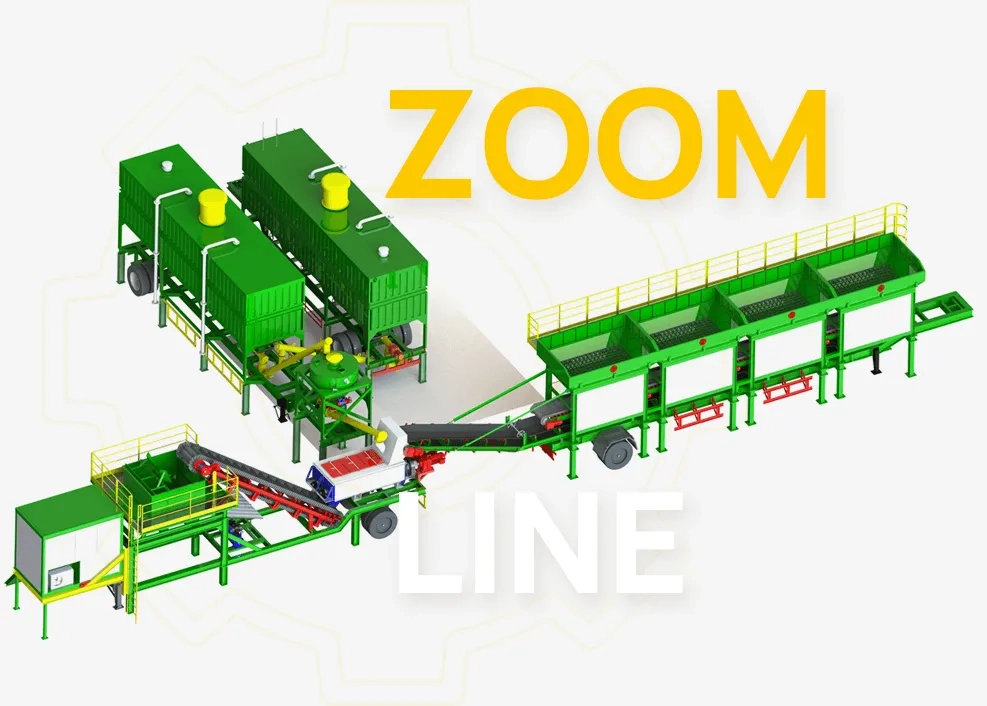

What is the warranty period for ZOOMLINE asphalt plant? What services are included during the warranty period?

The warranty period for our company's asphalt mixing plant is 15 months from the date of equipment acceptance. During the warranty period, we provide free replacement of parts and repair services caused by equipment quality issues (excluding damage caused by human error or force majeure). Outside the warranty period, we continue to offer lifetime technical support and discounted spare parts supply services.

How about the before sales service of ZOOMLINE company?

In the requirements communication phase, customers can reach out via phone, website messages, or in-person visits. Sales consultants gather key details like project scale, timeline, and material needs. For instance, for urban main road asphalt paving projects, they confirm road specifications and design lifespan to match suitable mixing plant equipment.

In the design phase, the technical team develops a customized asphalt mixing plant solution based on client requirements, covering model, configuration, layout, and workflow. They provide technical parameters and performance analysis to support feasibility assessment. For clients with limited space, a compact layout is designed to balance production efficiency and space use.

After the solution is finalized, the quotation and clarification phase begins. A transparent quotation outlines costs for equipment, transportation, installation, and commissioning. Sales consultants promptly answer questions, negotiate configurations and payment terms, and ensure clients have full clarity.

How about the sales service of ZOOMLINE company?

Contract Signing and Production Scheduling: After signing the formal contract, we will develop a production plan in accordance with the agreed-upon timeline and requirements. We will utilize advanced manufacturing processes and implement rigorous quality control measures to inspect components. Regular updates on production progress will be provided, enabling you to stay informed about the status of equipment manufacturing in real time.

Equipment Transportation and Installation/Commissioning: We will arrange for a professional team to transport the equipment, ensuring safe and timely delivery. On-site professionals will install and commission the equipment in accordance with established standards, conducting performance testing and optimization. You will be invited to participate in the final inspection and acceptance process.

Staff Training: We provide comprehensive training for operators and maintenance personnel, covering topics such as operational principles, procedures, maintenance, and fault handling.

How about the after sales service of ZOOMLINE company ?

We will send professional technical staff to client’s project working site to guide installing work, and commissioning the plant and training the operators of the buyer. And ZOOMLINE provide the technical support service within the whole service life of asphalt mixing plant.

7x24-hour after-sales service hotline is provided, allowing customers to report equipment faults at any time. Technical personnel respond within 1 hour and provide remote guidance or on-site repairs as needed: general faults are resolved within 24 hours, while complex faults are addressed with expedited solutions. All repairs use genuine original manufacturer parts to ensure quality and performance.

Relying on a comprehensive supply system, we ensure adequate spare parts inventory, providing timely delivery regardless of whether the equipment is within or outside the warranty period. Common spare parts are shipped quickly, while special custom parts are produced on an urgent basis. For customers outside the warranty period, we offer preferential prices and flexible supply options to meet equipment maintenance and repair needs.

What are the key points of daily maintenance for an asphalt mixing plant?

Daily maintenance primarily involves equipment cleaning, inspection, and lubrication. After each workday, residual materials must be removed from the mixing main unit, conveyor belt, and material storage silos to prevent material buildup that could impair normal equipment operation. Inspect all component connection bolts for loosening, check the conveyor belt for misalignment, and verify that electrical wiring is intact. Regularly lubricate bearings, chains, and other transmission components to extend equipment lifespan. Additionally, monitor the operational parameters of all systems to ensure normal functioning, and address any abnormalities promptly.

How often does the equipment require a comprehensive overhaul?

It is recommended to conduct a comprehensive overhaul every six months. During a comprehensive inspection, key components such as the mixing main unit, drying drum, vibrating screen, and hot material silo should undergo thorough inspection and maintenance. This includes checking the wear condition of the mixing blades and replacing severely worn blades; cleaning accumulated material and coke deposits inside the drying drum; and calibrating the accuracy of the weighing system. Additionally, the equipment should undergo a systematic maintenance and inspection annually to ensure long-term stable operation.