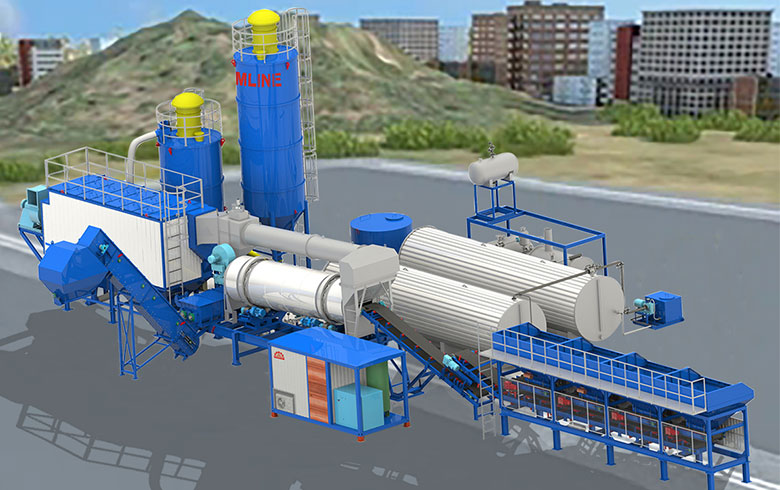

I.ZAP-C(M) series Continuous Asphalt Mixing Plant

ZOOMLINE ZAP-C(M) series asphalt mixing plant is a continuous type asphalt mixing plant that can produce the asphalt mixture continuously. It is very different from the batch asphalt mixing plant.

Main Features of ZAP-C(M) series Continuous Asphalt Mixing Plant

1.Simple structure, easy to move and maintain, and with low equipment investment.

2.Concurrent type drying drum structure, the efficiency of heating aggregate is much higher than downstream type, fuel consumption is lower, and save energy.

3.Separated continuous type mixer, the mixing performance is high and make sure the quality of asphalt mixture.

4.Scraper type elevator take the asphalt mixture cleaning and smoothly.

5.Can be equipped with RAP and filler system.

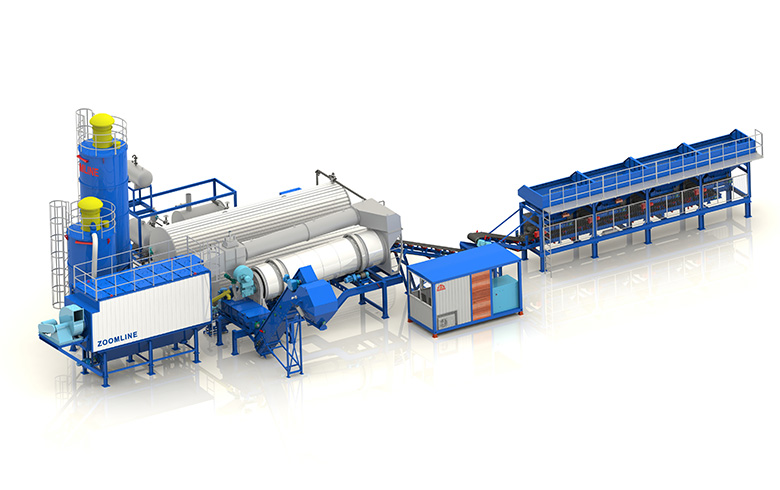

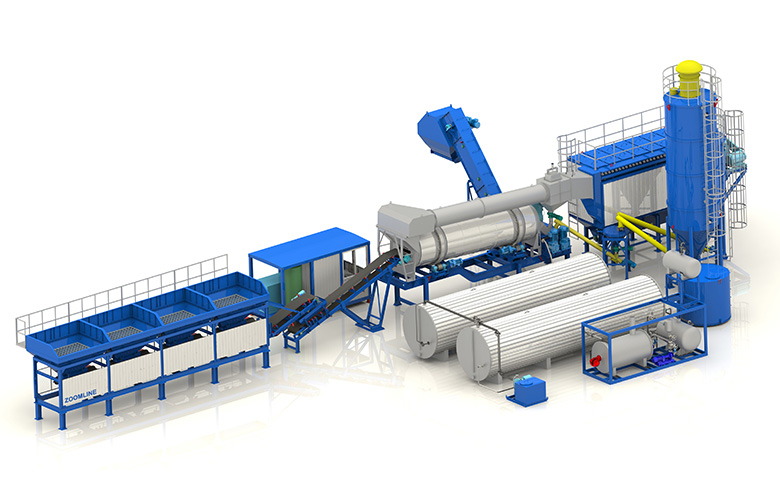

II.DHB series Asphalt Drum Mix Plant

The basic components of the DHB series asphalt mixing plant include a cold material supply system, filter, drying drum, elevator, dust collector, finished product silo, bitumen supply system, and photoelectric control system.

Features of DHB series Asphalt Drum Mix Plant

1.Modular design with a rational layout and structure. This enables the equipment to be quickly transferred to different locations, making it convenient for transportation, installation, and debugging.

2.Simple structure that is easier to diagnose faults. This makes daily maintenance more convenient and cost-efficient, while saving on labor costs.

3.A large number of maintenance-free parts are used, which reduces procurement and repair costs. It optimizes power configuration, thereby saving on energy resources. The use of advanced combustion technology results in the lowest fuel consumption, thus guaranteeing the lowest production energy consumption costs.

4.Intelligent control system with high-quality electrical components: Advanced system control technology is used, along with internationally renowned brands of high-quality control hardware. This makes the control system reliable, expandable, and easy to maintain.