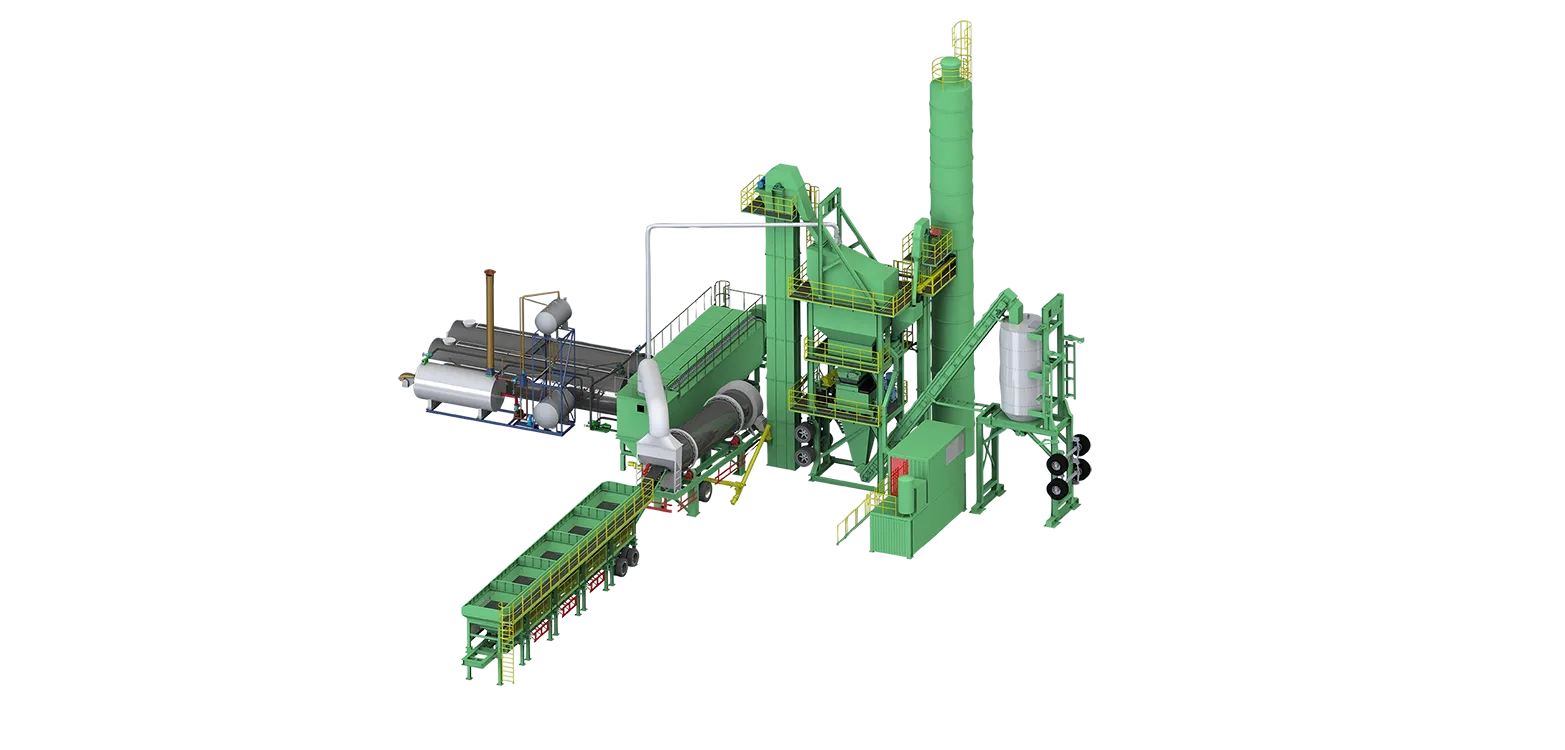

| Model | ZAP-M60 | ZAP-M80 | ZAP-M100 | ZAP-M120 | ZAP-M160 | ZAP-M200 | ZAP-M240 | ZAP-M320 |

| Plant Capacity | 60t/h | 80t/h | 100t/h | 120t/h | 160t/h | 200t/h | 240t/h | 320t/h |

| Cold Aggregate Feeding System | ||||||||

| Hopper Capacity | 4 x 4.5m³ | 4 x 6.5m³ | 4 x 6.5m³ | 4 x 8m³ | 5 x8m³ | 5 x 12m³ | 5 x 12m³ | 5 x 15m³ |

| Belt Capacity | 80t/h | 100t/h | 120t/h | 140t/h | 180t/h | 220t/h | 260t/h | 260t/h |

| Drying System | ||||||||

| Drying Drum Size | 1500x6000mm | 1500x6600mm | 1500x6600mm | 1800x8000mm | 1950x9000mm | 2200x9000mm | 2400x9000mm | 2600x9000mm |

| Drying Capacity | 60-80t/h | 80-100t/h | 100-120t/h | 120-140t/h | 160-180t/h | 200-220t/h | 240-260t/h | 320-340t/h |

| Burner (oil) | Oil, Natural gas(optional) | |||||||

| Mixing Tower | ||||||||

| Screen | 4 layers | 4 layers | 4 layers | 4 layers | 4/5 layers | 5 layers | 5 layers | 5 layers |

| Aggregate Weighing | 3x800kg | 3x1000kg | 3x1500kg | 3x1500kg | 3x2000kg | 3x3000kg | 3x3000kg | 3x5000kg |

| Bitumen Weighing | 3x80kg | 3x100kg | 3x200kg | 3x200kg | 3x200kg | 3x500kg | 3x500kg | 3x550kg |

| Filler Weighing | 3x100kg | 3x100kg | 3x200kg | 3x200kg | 3x200kg | 3x500kg | 3x500kg | 3x500kg |

| Mixer Capacity | 800kg | 1000kg | 1300kg | 1500kg | 2000kg | 2500kg | 3000kg | 4000kg |

| Mixing Cycle | 45s | |||||||

| Dust Collecting System | ||||||||

| Bag House Filtering | 300m² | 380m² | 400m² | 500m² | 550m² | 650m² | 700m² | 1050m² |

| Exhaust Fan Power | 37kW | 45kW | 55kW | 75kW | 90kW | 110kW | 160kW | 200kW |

| Asphalt Temperature | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ | 140-180 ℃ |

| Finished Asphalt Silo (Optional) | 15 ton | 30 ton | 30 ton | 30 ton | 60 ton | 100 ton | 100 ton | 100/200 ton |

| Total Power | ≈185kw | ≈270kw | ≈300kw | ≈390kw | ≈500kw | ≈570kw | ≈640kw | ≈800kw |

*Plant capacity is base on standard working condition as followings:

| Atmospheric pressure | 760mmHg |

| Ambient temperature | 20℃ |

| Material passing 40mm mesh | 100% |

| Material passing 3mm mesh | 40% |

| Material passing 74µm | ≤7% |

| Aggregate temperature at discharging end of drum dryer | 160℃ |

| Density of aggregate | 1650kg/m³ |

| Specific heat of aggregate | 0.21kcal/kg℃ |

| Filler content | 5% |

| Bitumen content | 5% |

| Sand content | ≤40% |

| Max.aggregate size | ≤40mm |

| Average moisture of cold aggregates | ≤5% |

| Cycle time per batch | 45s |

| Diesel calorific value | ≥10500Kcal/kg |

| Heavy oil calorific value | ≥9850Kcal/kg |

| Nature gas calorific value | ≥8000Kcal/Nm³ |

| Coal calorific value | ≥5500Kcal/kg |