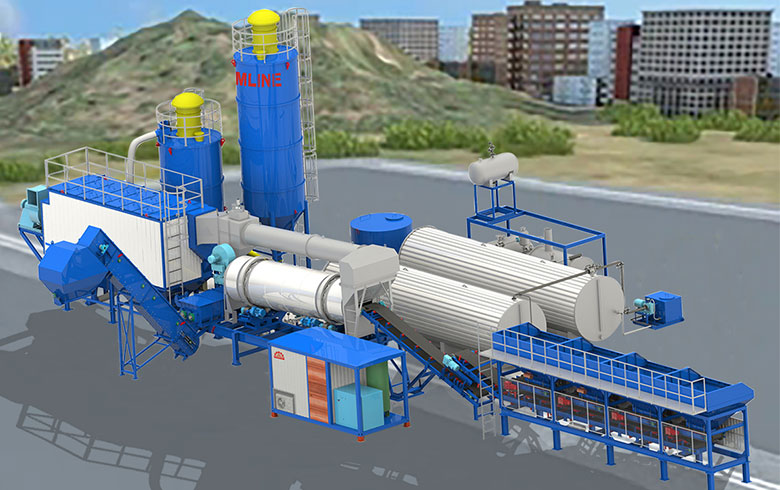

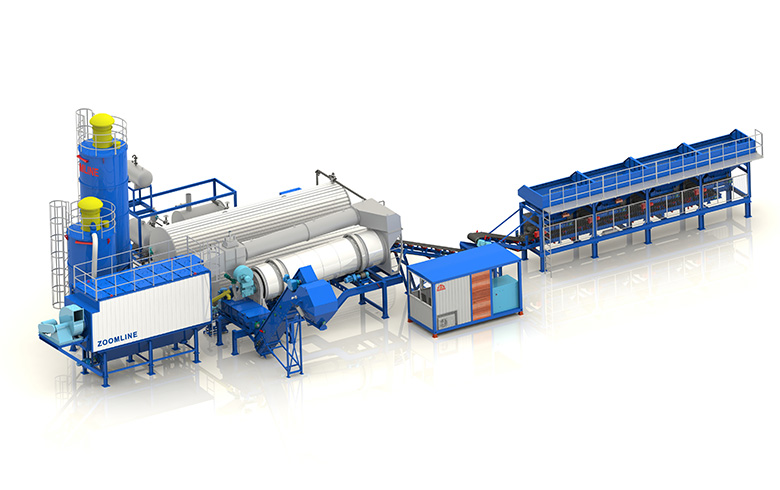

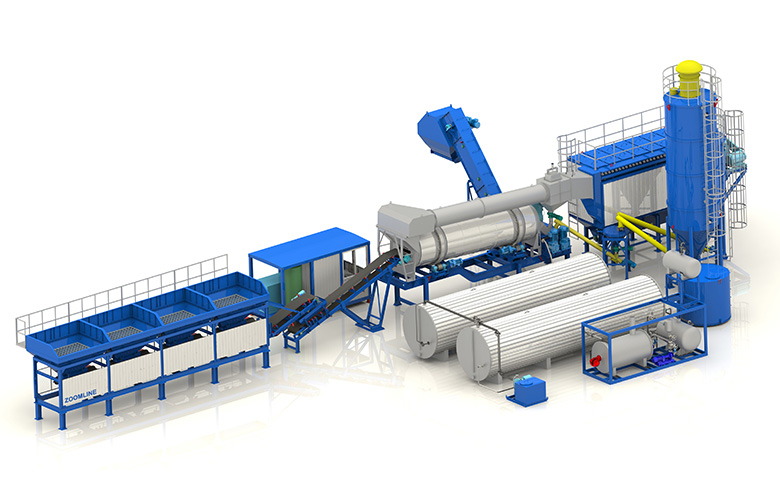

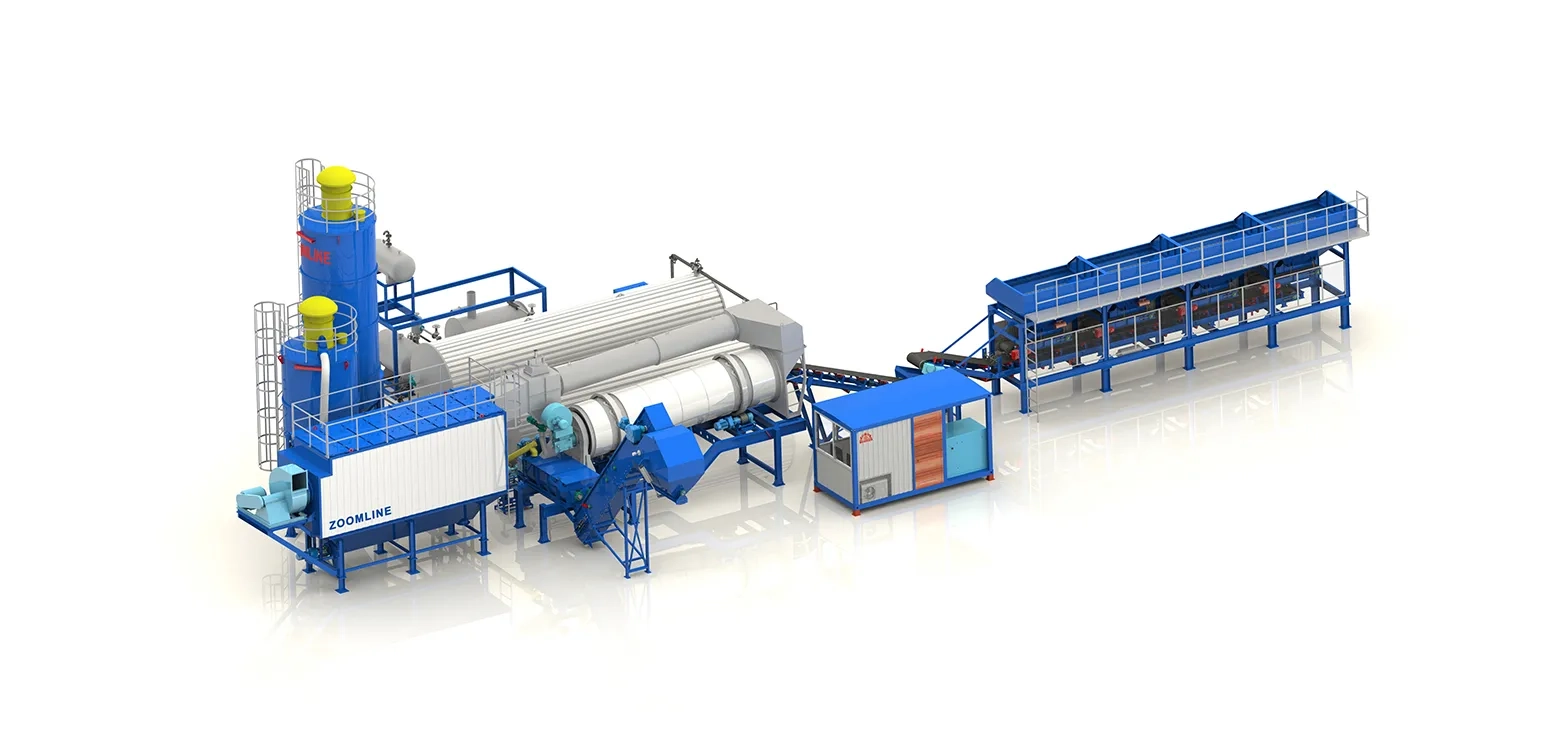

The stable operation of the continuous asphalt plant depends on the cooperative work of the core components, each of which bears a key function and has targeted advantages.

Cold Aggregate Feeding System

Cold Aggregate Supply System consists of cold silo, belt feeder, primary aggregate feeder and conveyor, recycled aggregate feeder and conveyor, which adopts modular design and is equipped with environmental protection system, which not only realizes the precise delivery of aggregate, but also reduces the dust leakage in the process of operation, and adapts to the synergistic supply demand of primary and recycled aggregate.

Drying & Heating System

The drying and heating system consists of primary material drying drum, recycled material drying drum, burner, air compressor, heavy oil tank and light oil tank. The core function is to dry and heat the cold aggregate uniformly, to ensure that the temperature of the aggregate reaches the requirement of subsequent mixing, and to lay a foundation for the stability of the quality of the asphalt mixture.

Lifting System

The lifting system consists of hot aggregate lifter, recycled material lifter and powder lifter. After the aggregates are heated to the set temperature, the hot aggregate and recycled material lifter will transport the materials to the corresponding screening equipment, while the powder lifter will send the virgin and recycled fillers to the storage bin respectively, so as to realize the orderly transfer of materials.

Mixing System (Continuous Mixer)

Equipped with horizontal twin-shaft paddle mixer, vibrating mixer, centralized lubrication system and main frame, it can fully mix the aggregate, filler and bitumen after quantitatively weighing according to the set ratio to ensure the homogeneity of the finished mixture and meet the project quality standard.

Baghouse Dust Removal System

Bag-type dedusting system consists of snail shell collector, main dust collector bag and induced air system, and regeneration material induced air system, which can not only increase the pressure difference between the two ends of the drying drum, improve the passing rate of the hot airflow, optimize the heating and drying effect, but also reduce the concentration of flue gas and dust emission, which is in line with the environmental standards; at the same time, the duct connects with vibrating screen, which can remove the floating dust in the screen bin, provide a negative-pressure environment for the aggregate conveying channel, and reduce dust leakage of each sealing part. Meanwhile, the air duct is connected to the vibrating screen, which can remove floating dust in the screen bin and provide a negative pressure environment for the aggregate conveying channel, thus reducing the dust leakage in all sealed parts.

Filler Feed System

The powder supply system includes primary filler bin, regeneration filler bin, regeneration filler storage bin, filler screw conveyor and waste powder screw conveyor. Primary and regeneration filler can be put into use directly after weighing, and waste powder with high impurity content will be discharged from the system through a special conveyor to ensure the purity of filler.

Bitumen Supply System

The bitumen supply system consists of high-temperature bitumen tank, high-temperature bitumen mixing tank, bitumen discharge tank, bitumen pump and heat-conducting oil system, which is responsible for storing and delivering asphalt quantitatively to ensure the stability and accuracy of the asphalt supply to meet the rhythm of continuous production.

Pneumatic Circuit System

The pneumatic system is equipped with air compressor, air filter, dryer and pneumatic components, and there is one set of independent pneumatic circuit for each raw material and recycled material system, which ensures the stable operation of each pneumatic component and avoids the impact of the overall production efficiency due to the failure of the pneumatic circuit.

Control System

The control system adopts German Siemens electrical components, which can operate stably under adverse working conditions; with Japanese OMRON PLC and touch screen, it has strong data processing capability, supports automated data table control, and can store all kinds of real-time operating data; all system power switches can be operated through the control panel, which is convenient and efficient, and the protection level of the control cabinet reaches IP55, which is in line with the highest standards of the global industry.