| Model

| ZAP-S80 &RAP60 | ZAP-S120 &RAP60 | ZAP-S120 &RAP80 | ZAP-S160 &RAP80 | ZAP-S160 &RAP120 | ZAP-S200 &RAP120 | ZAP-S240 &RAP120 | ZAP-S240 &RAP160 | ZAP-S320 &RAP160 |

| Raw Material Production Capacity (under standard conditions) | 80T/H | 120T/H | 120T/H | 160T/H | 160T/H | 200T/H | 240T/H | 240T/H | 320T/H |

| RAP Production Capacity (under standard conditions) | 60T/H | 60T/H | 80T/H | 80T/H | 120T/H | 120T/H | 120T/H | 160T/H | 160T/H |

| Total Output of Equipment (under standard conditions, including RAP) | 120T/H | 180T/H | 200T/H | 240T/H | 280T/H | 280T/H | 320T/H | 360T/H | 400T/H |

| Installed Power(kW) | 265+130 | 370+130 | 370+150 | 500+150 | 500+210 | 570+210 | 640+210 | 640+300 | 870+300 |

| Emission Concentration | <30mg/Nm³ (Bag house dust filter) | ||||||||

| Environmental Noise | <80 db (control room) | ||||||||

| Mixer Capacity(kg/batch) | 1500 | 2000 | 2500 | 3000 | 3500 | 3500 | 4000 | 4500 | 5000 |

| Measuring Accuracy | Static: Aggregate: 0.5% Powder: 0.3% Asphalt: 0.2% Recycled material: 0.5% Additive: 0.2% | ||||||||

| Filtering Area | 650m² | 700m² | 770m² | 1050m² | 1150m² | 1150m² | 1350m² | 1350m² | 1600m² |

| RAP Add Ratio | 50% | 50% | 50% | 30% | 40% | 40% | 35% | 50% | 40% |

| Finished Asphalt Silo | Side mounted(Optional) | ||||||||

| Optional Items

| Bitumen smoke treatment system | ||||||||

| The whole station package and dust collecting system | |||||||||

| Foam asphalt system (warm mixing system) | |||||||||

The advantages of recycling asphalt plant are concentrated in the three dimensions of environmental protection, resource saving and operation cost control, which accurately solves the core pain points of the traditional asphalt mixing mode, which not only conforms to the policy guidance, but also brings real economic benefits and social value to the enterprise, and is one of the optimal choices for the transformation of the industry.

Recycling asphalt plant effectively reduces the pollution of waste asphalt pavement materials to the environment, practicing the policy compliance and corporate social responsibility. In the traditional mode, the waste asphalt pavement materials are mostly processed by landfill, which not only occupies a large amount of land resources, but also may pollute the soil and water; while the recycling asphalt plant can recycle and reuse the waste asphalt pavement materials, which completely avoids the accumulation of the waste materials and landfill, and minimizes the occupancy and waste of the land resources. At the same time, the equipment is equipped with professional fume treatment system, the harmful gases and dust that may be generated in the regeneration process are purified and then discharged, which greatly reduces the pollution to the atmosphere and water system, and can easily meet the environmental standards around the world.

Recycling asphalt plant realizes the recycling of resources, which has important strategic value and cost reduction potential. Waste asphalt pavement materials (RAP) contained in the aging asphalt and aggregate, after regeneration treatment can be reapplied to asphalt pavement construction, an effective alternative to some of the new asphalt and aggregate mining needs, not only saves limited natural resources, but also reduces the dependence of the enterprise on the raw material market, especially in the fluctuation of raw material prices is large at the present time, can effectively avoid the risk of raw material prices, for the stability of the enterprise to provide a guarantee of production. Guarantee. Enterprises can initially estimate the amount of asphalt and aggregate to be saved every year according to their own production scale, and intuitively feel the value brought by resource recycling.

The long-term comprehensive advantage of recycling asphalt plant is very outstanding, which can effectively help enterprises reduce operation cost and improve profit space. Although the initial investment of the equipment is relatively high, but from the long-term operation point of view, the equipment can realize on-site recycling, on-site regeneration production, completely eliminating the transportation cost of waste materials and the procurement of new raw materials, transportation costs, significantly reducing the cost of pre-production input; at the same time, the production cost of recycled asphalt mixture is much lower than that of the new asphalt mixture, which can further reduce the overall cost of pavement maintenance and repair. With the extension of the production cycle, the cost advantage of the equipment will become more and more obvious.

| Comparison Dimension | Traditional Asphalt Mixing Plant | Recycling Asphalt Plant |

|---|---|---|

| Core Definition and Design Initial Purpose | The core production of brand new asphalt mixture, relying on virgin raw materials, without RAP processing regeneration function, is the unidirectional mode of “resource consumption - output of finished products”, which is applicable to the demand scenarios of purely new materials, such as new roads. | The core is RAP resource regeneration + mix production, solving the problem of RAP waste and pollution, realizing the closed loop of “recycling - processing - regeneration - reuse”, taking into account the environmental protection and cost, and it is the core equipment for green transformation of the industry. |

| Core Equipment Configuration | Consists of new aggregate feeding, drying drum, screening, hot material silo, asphalt storage and heating, mixing machine, dust removal and control system, which is centered around the processing of virgin raw materials without RAP-specific processing module. | On the basis of traditional configuration, new RAP processing system (crushing, screening, storage), regenerant/modifier adding system, optimized heating mixing and control system can realize precise intelligent regulation and control of RAP proportioning, etc., with metering deviation ≤ 0.1%. |

| Workflow | Unidirectional Flow: primary raw material preparation → new aggregate heating (150-180℃) → sieving → metering → mixing → discharging and transporting, no waste material processing, suitable for large-scale pure new material production. | Closed-loop process: divided into two stages of RAP pre-processing (milling and recycling → transportation → crushing and screening → moisture-control storage) and regeneration production (RAP+new raw material preparation → heating → metering → mixing → testing → reuse), realizing resource recycling. |

| Environmental Performance | Weak environmental protection, RAP is mostly landfilled and discarded, which is wasteful and polluting; high energy consumption in production, high tail gas and dust emission, additional investment is needed to optimize the environmental protection system. | Outstanding environmental performance, more than 80% of RAP can be reduced to landfill; energy consumption is reduced by 20%-30%, carbon emission is reduced by more than 40%; RAP heating temperature is low, less smoke, more efficient environmental control. |

| Cost-effectiveness | 1. Low equipment investment, simple structure, suitable for projects with limited budget and only need new material production; 2. High operation cost, totally dependent on new raw materials, high energy consumption, fuel consumption about 6.5kg/t finished material. | 1. Equipment investment is 20%-50% higher than traditional, can be reduced through the transformation of traditional mixing plant investment; 2. Low operating costs, RAP mixing 20%-70% (some can be 100%), significantly reduce the amount of new raw materials, long-term rapid recovery of initial investment. |

| Applicable Scenarios and Product Performance | Applicable Scenarios: New high-grade highways, airport runways and other projects with very high requirements for mix performance, requiring pure new material, and areas with low RAP production. Product Performance: Stable and up to standard, long service life, low difficulty in quality control. | Applicable Scenario: Road maintenance, old road renovation and other RAP production of large projects, environmental protection policy is more suitable for the region, can take into account the production of new materials and recycled materials. Product Performance: Depends on the mixing amount of RAP and proportion, scientific control can be close to the standard of new materials, the performance of the fluctuation is slightly larger, the operation and monitoring requirements are higher. |

| Operation and Maintenance | Simple operation, quick for operators to get started; clear focus on maintenance, mature process, low cost, no need for professional recycling technicians. | Difficult to operate, need professional technology; maintenance points, slightly higher costs, technology upgrades maintenance process has been simplified. |

With the continuous maturity of asphalt regeneration technology, the application scenarios of recycling asphalt plant are constantly expanding, and have been widely used in various types of pavement construction and maintenance scenarios, which can effectively solve the pain points of the traditional construction mode, and meet the production needs of different users, which mainly focuses on the following four major scenarios.

asphalt regeneration mixing equipment can quickly deal with the waste pavement materials, which can be directly used for pavement pothole repair, new pavement base paving and other operations after regeneration processing, which not only shortens the construction cycle, but also realizes the on-site utilization of the waste materials, reduces the amount of materials transported in the process of construction, and reduces the interference to the urban traffic, which is very suitable for the construction needs of the urban construction contractors.

The on-site regeneration capability of the equipment plays an important role. Highway maintenance of traffic impact control requirements are extremely high, asphalt regeneration mixing equipment can be completed on-site recycling of waste pavement materials, regeneration and paving, significantly shorten the time of traffic closure, minimize the impact of maintenance operations on highway traffic, is the ideal equipment for highway maintenance departments.

The advantages of recycling asphalt plant are more obvious. Remote areas have inconvenient traffic, high cost and long period of long-distance transportation of new raw materials, while mobile recycling asphalt plant can realize on-site operation without long-distance transportation of new raw materials, which can not only save the transportation cost, but also shorten the construction period, which effectively solves the pain point of the construction in remote areas, and is highly favored by the operators of remote projects.

Recycling asphalt plant can meet the requirements of international green building certification on material recycling, effectively improve the sustainability of the project, help the project to obtain green certification, suitable for enterprises focusing on green project construction.

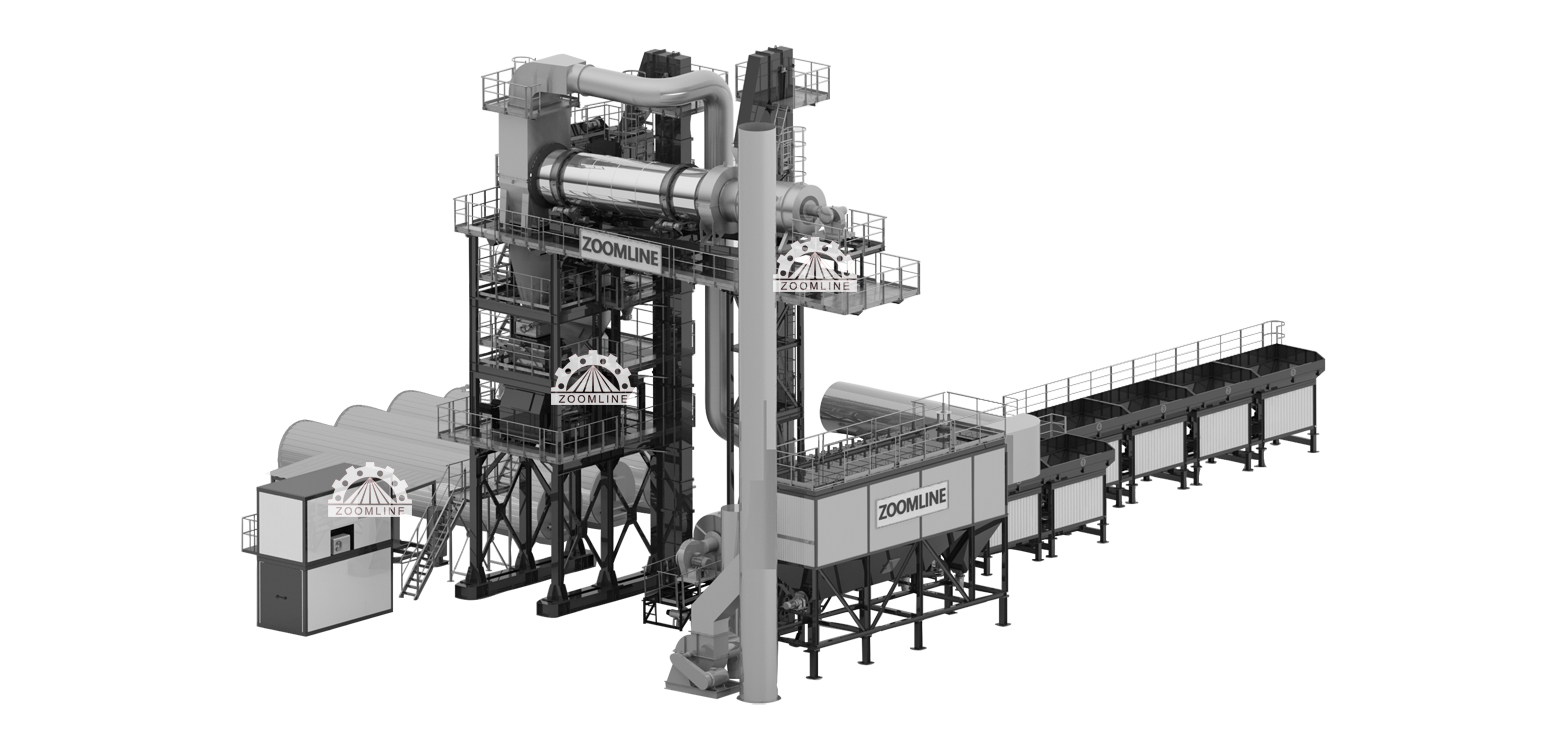

The performance of recycling asphalt plant directly depends on the quality and suitability of its core components, the plant mainly consists of 12 core systems, the systems operate in concert to ensure the high efficiency, precision and environmental protection of recycled asphalt production, the specific details are as follows:

The system consists of cold silo, belt feeder, primary aggregate feeder, primary aggregate belt conveyor assembly, recycled aggregate feeder, recycled aggregate belt conveyor assembly, and is equipped with professional environmental protection system, and adopts the modular structure design, not only easy to install and dismantle, but also can effectively reduce the production of The system consists of cold hopper, belt feeder, primary aggregate feeder, primary aggregate belt conveyor assembly, regeneration aggregate feeder, regeneration aggregate belt conveyor assembly, equipped with professional environmental protection system, and adopts the modular structure design, which is not only convenient to install and dismantle flexibly, but also effective in reducing the dust leakage in the process of production, taking into account both the environmental protection and the practicality, and is able to meet the adaptive needs of different scale of production.

The drying and heating system is used for drying and heating of cold aggregate, which mainly consists of drying drum for virgin material, burner, air compressor, drying drum for recycled material, burner, air compressor, as well as storage tank for heavy oil and light oil, which can accurately control the heating temperature of the virgin and recycled material and adapt to the processing demand of the high proportion of recycled material to avoid the aging of the recycled material due to excessive heating, and protect the recycled asphalt from overheating and aging. Aging, to protect the quality of recycled asphalt, while taking into account the rationality of energy consumption.

When the aggregate and recycled materials are heated to the set temperature, the hot aggregate elevator and recycled material elevator will elevate the corresponding materials to the respective screening equipment, at the same time, the powder elevator will elevate the primary filler and recycled filler to the corresponding storage silo, in order to prepare for the subsequent screening and metering processes.

The system consists of multi-layer vibrating screen, of which the primary material vibrating screen up to 6 layers (can be customized), recycled material vibrating screen standard configuration for the 2 layer or 3 layer (can be customized), the core role is to screen out the aggregate required for each particle size class to ensure that the subsequent mixing process of the aggregate gradation is accurate, the whole system is running efficiently and stably to ensure the continuity of production.

Metering System is the key to ensure the accuracy of the recycled asphalt mixture formula, consisting of raw material hot aggregate weighing device, filler weighing device, asphalt weighing and spraying device, recycled material weighing device, recycled material storage hopper weighing device, the weighing sensors will be the real-time output signals, and in the form of intuitive dynamic form on the display, to facilitate real-time monitoring and precise control of the operator.

Mixing system mainly consists of horizontal biaxial paddle mixer, vibrating mixer, centralized lubrication system and the main structure of the mixing plant, its core function is to quantitatively weigh the aggregate, filler and asphalt, in accordance with the set ratio of homogeneous mixing, and ultimately formed in line with the requirements of the finished product of the recycled asphalt mixture, mixing homogeneity directly determines the recycled asphalt pavement application performance.

Dust removal system is the core guarantee of the environmental performance of the equipment, which consists of the snail shell collector, the bag collector of the main dust collector and the induced air system, and the reclaimed material induced air system, which not only increases the pressure difference between the two ends of the drying drum, enhances the passing capacity of the hot airflow, optimizes the heating and drying effect, but also controls the concentration of the flue gas and dust emission within the range of the global environmental protection standards. At the same time, the air duct is connected to the vibrating screen, which can effectively remove the floating dust in the vibrating screen chamber and form negative pressure in the aggregate conveying channel, greatly reducing the possibility of dust leakage in each sealed part and practicing the concept of environmentally friendly production.

The system consists of primary powder silo, recycled powder silo, recycled powder storage silo, powder screw conveyor, waste powder screw conveyor, in which the primary powder and recycled powder can be put into production and use directly after weighing, and the waste powder with high content of impurities will be discharged out of the system through the waste powder screw conveyor, so as to avoid affecting the quality of the recycled asphalt mixture.

The bitumen supply system is responsible for storing and delivering bitumen, mainly composed of high-temperature bitumen tanks, high-temperature bitumen mixing tanks, bitumen discharge tanks, bitumen pumps and thermal oil system, which can accurately store and deliver quantitative bitumen according to the production demand and guarantee the accurate and controllable bitumen dosage in the mixing process.

The pneumatic system consists of air compressor, air filter, air dryer and pneumatic components, one set for each raw material system and recycled material system, which can provide stable, dry and clean air source for the pneumatic control of each part of the equipment, and guarantee the precise and smooth operation of each action of the equipment.

The electrical control system adopts intelligent design, which consists of control room, desktop combination console, wall-mounted control elements, advanced commercial computer, printer, tool box, cabinet dual-temperature air conditioning, and can realize three control modes: fully automatic, semi-automatic and manual. The whole system runs accurately, efficiently and stably, which can reduce manual intervention, lower the operation difficulty and human error, and at the same time reduce the intensity of manual labor, and solve the problem of the enterprise's labor force. Labor intensity, to solve the pain point of high labor costs.

Recycled asphalt adding system can improve the production efficiency of the mixing plant to help users reduce the cost of investment in equipment, hot recycling asphalt plant through a special drying drum to complete the heating operation of recycled asphalt, and the system is usually used in conjunction with the asphalt mixing plant, mainly by the recycled asphalt feeding system, material material lifting system, drying system, recycled asphalt hopper, recycled asphalt weighing system, dust removal system and control system. system, dust removal system and control system.

Recycling asphalt plant workflow is clear and coherent, mainly divided into four core steps, from waste material recycling and processing to the final regeneration of pavement molding, the whole process to achieve closed-loop operation, which not only ensures the utilization of recycled materials, but also protects the quality of the recycled asphalt mixture, the specific working principle is as follows.

First of all, the fatigue damage to the asphalt pavement after milling, collection, to get the waste asphalt pavement materials (RAP), and then through the recycling asphalt plant crushing, screening device, the RAP material crushing, grading process, screening out the production requirements of the aggregates and asphalt mixture, to remove impurities and unqualified particles, for the subsequent heating, mixing operations to lay the foundation for this step in the processing results The processing effect of this step directly affects the quality of the final recycled asphalt mixture.

After crushing and screening the qualified RAP material into the heating device, preheating and drying process, the main purpose is to remove the water and residual impurities in the RAP material, to avoid moisture to affect the subsequent mixing effect and the bonding of recycled asphalt, and at the same time, through the precise control of the heating temperature, to prevent the recycled asphalt aging due to overheating, to ensure that recycled asphalt performance is stable, this step is to ensure that the recycled mixture quality of the key link. This step is the key link to ensure the quality of recycled mixture.

Preheated and dried RAP material into the mixing device, in accordance with the preset ratio, add new asphalt, recycling agent and other additives, in a high-temperature environment for full mixing to ensure that the RAP material, new asphalt, recycling agent and additives are evenly mixed to form a recycled asphalt mixture with excellent performance. This step requires strict control of the mixing ratio of each material and mixing time, mixing temperature, to ensure the uniformity and stability of the mixture to meet the quality requirements of pavement construction.

Paving and Compaction

Will be evenly mixed recycled asphalt mixture transported to the construction site, through paving, compaction and other construction processes, the recycled asphalt mixture paved in the pavement grass-roots level, after compaction molding, the formation of qualified recycled asphalt pavement, to complete the entire recycling process of waste asphalt pavement materials. The entire workflow is interlocked, each step needs to strictly follow the operating specifications, in order to ensure production efficiency and product quality.

ZAP-S160&RAP80 Recycling Asphalt Plant, Raw Material Production Capacity (under standard conditions)160T/H, RAP Production Capacity ( under standard conditions)80T/H, Total Output of Equipment (under standard conditions, including RAP) 240T/H, Installed Power(kW)500+150

High-efficiency regeneration, strong capacity adaptability

Reasonable matching of capacity: ZAP-S160 raw material capacity of 160t/h, RAP80 recycled material capacity of 80t/h, synergistic and continuous production, suitable for medium and large-scale road construction, taking into account the output and efficiency.

Stable regeneration ratio: 30%-50% of RAP is added to make full use of the old material, reduce the consumption of virgin material, lower the cost, and at the same time guarantee the stable quality of the mixture.

Durable core components: The drying drum and mixing cylinder adopt wear-resistant components, optimize the capacity to meet the mixing demand, reduce loss, extend the service life, and reduce maintenance costs.

Energy saving and consumption reduction, controllable operation cost

Energy efficient combustion: equipped with high efficient medium atomization burner, low fuel consumption; drying drum optimization, hot air recycling, heat preservation in place, reduce heat loss.

Modular energy saving: modular layout of the whole machine, can be flexibly adjusted to avoid ineffective energy consumption; part of the components frequency control, further reducing power consumption.

Green environmental protection, emission compliance

Omni-directional dust and smoke removal: double dust removal system, dust emission ≤ 30mg/Nm³; asphalt flue gas secondary combustion, flue gas blackness up to Ringlemann level 1, in line with environmental standards.

Closed design: the whole machine and conveying system is closed, and the sand silo is equipped with anti-arch device to reduce dust and smoke leakage and realize green production.

Intelligent and convenient, save operation and maintenance

Precise and intelligent control: computerized automatic control, integrated temperature monitoring, precise weighing function, accurate measurement, automatic adjustment of parameters, to ensure the quality of the mixture.

Convenient installation and movement: modular design, containerized transportation, no need for traditional foundation, quick installation and dismantling, convenient maintenance.

Strong expandability: the function can be flexibly expanded to meet the customized needs, and can be compatible with the original asphalt plant to enhance economic efficiency.

Reliable quality, wide range of adaptable scenes

Guaranteed quality: ISO9001 and CE certified, with perfect warranty for core components, stable operation, and remote troubleshooting support for part of the equipment.

Applicable to a variety of scenes: can be used in various types of highway, municipal pavement recycling construction, can handle different specifications of the old asphalt mixture, both practical and economic.

Choosing the right recycling asphalt plant is to ensure production efficiency, product quality and operational efficiency of the key, the production needs of different enterprises, site conditions, there are differences in the budget, equipment selection needs to be combined with their own actual situation, focusing on the following four core dimensions, to avoid the waste of resources or production bottlenecks caused by blind selection.

The old material processing capacity of the equipment needs to be matched with the enterprise's daily production demand, according to their own daily and monthly RAP material processing volume, select the corresponding size of the equipment, not only to avoid the equipment processing capacity is insufficient to meet the production demand, resulting in delays in the work schedule; but also to avoid the excess capacity of the equipment processing capacity, resulting in idle equipment and waste of investment, to achieve the precise match between production capacity and demand.

In the context of global low-carbon policies and rising energy prices, the energy-saving nature of the equipment directly affects the long-term operating costs, selection should be given priority to the use of low-energy heating methods, energy-saving components of recycling asphalt plant, not only to reduce energy consumption, reduce operating costs, but also to meet the carbon emission standards, in line with the industry's low-carbon development trend, to achieve a win-win situation for environmental protection and efficiency.

Priority is given to equipment equipped with automation control system, the automation control system can reduce manual intervention, reduce the operating difficulty, reduce human error, while reducing manual labor intensity, reduce the cost of labor for the enterprise, especially suitable for enterprises with insufficient technical operators. In addition, the ease of maintenance of the equipment also needs to focus on, choose a reasonable structure, easy to disassemble, easy to maintain the equipment, can reduce equipment downtime, improve production efficiency.

Different construction scenarios on the requirements of the equipment there are differences, such as high temperature, cold areas need to choose to adapt to the special conditions of the customized equipment, airport runways, industrial floor construction need to choose high-precision customized equipment, so the selection of their own scene needs to be clear, to choose the ability to provide customized services to the equipment manufacturers; at the same time, improve the after-sales service can be a timely solution to the equipment used in the process of faults and problems, to improve production efficiency. At the same time, perfect after-sales service can solve the faults and problems in the process of equipment use in a timely manner to reduce the loss of downtime, so you need to choose the perfect after-sales service, timely response, strong technical strength of the manufacturer, to protect the long-term stable operation of the equipment.

The maintenance of recycling asphalt plant is relatively complex, this complexity mainly stems from the specificity of its process, the high degree of integration of the equipment and the strict requirements for environmental protection and quality control, and many enterprises in the process of using the equipment, due to improper maintenance, resulting in frequent failures of the equipment, shortening the service life, and increasing the operating costs. Clearly maintain the core reasons for the complexity, and take targeted response strategy, can effectively improve the efficiency of equipment maintenance, to ensure stable operation of the equipment.

The process is complex, high degree of equipment integration, recycling asphalt plant needs to complete the RAP material crushing, screening, heating, mixing and other aspects of the operation, compared with the traditional asphalt mixing equipment, the increase in the RAP material pre-treatment, low-temperature heating system and other specialized equipment, the automation of these equipments, the degree of intelligence is high, the entire structure of the production system more complex, any one link of equipment failure, may affect the normal operation of the entire production process, increasing the difficulty of maintenance.

The recycling asphalt plant performance and reliability requirements are stringent, the quality of recycled asphalt mixture is directly related to the service life of the pavement and traffic safety, so the equipment must operate stably for a long period of time, to ensure that the aggregate gradation, asphalt dosage, heating temperature and other key parameters of the precise control of any equipment, any minor deviation may lead to the mixture quality does not meet the standards, resulting in mass production accidents, which is the precision of recycling asphalt plant maintenance. This puts forward higher requirements on the accuracy and timeliness of recycling asphalt plant maintenance.

The additional challenges brought by environmental protection and safety regulations, in the RAP material heating process, easy to produce smoke and asphalt aging problems, in order to meet the stringent environmental standards, the equipment is equipped with a special dust removal, smoke removal system, these environmental protection equipment itself needs regular maintenance, and its operating status is closely related to the performance of the main production for recycling asphalt plant, which further increases the complexity of the maintenance work and workload.

The transformation to predictive maintenance, abandon the traditional “broken and then repair” passive maintenance mode, in the key components of the recycling asphalt plant (such as motors, bearings, drying drum) on the deployment of Internet of Things sensors, real-time monitoring of recycling asphalt plant temperature, vibration and other operating data, combined with AI algorithms to analyze the operating state of the recycling asphalt plant, in advance to predict the possible failure of the recycling asphalt plant, to achieve “before the disease, before the disease”. The company also realizes “prevention before disease” to effectively reduce the risk of sudden recycling asphalt plant downtime and reduce downtime losses.

It implements refined maintenance management, builds an intelligent operation and maintenance platform, integrates equipment files, maintenance records, spare parts inventory and other information into the platform, realizes the scientific formulation of maintenance plans, standardized management of the maintenance process, and accurate control of spare parts inventory, ensures “zero shortage” of key spare parts, and reduces downtime due to waiting for spare parts. At the same time, it optimizes the maintenance process and improves maintenance efficiency and quality.

RAP pile management quality, directly affecting the productivity of recycling asphalt plant and the quality of recycled asphalt mixtures, many companies due to the neglect of the RAP pile management, resulting in the quality of the recycled mixture is unstable, the production of energy consumption increases, so mastering the best practices of the RAP pile management to optimize the production operation and cost reduction Therefore, mastering the best practices of RAP stockpile management is important for optimizing production operations and reducing costs. The following are the 5 core best practices, adapted to the production needs of recycling asphalt plants, simple and easy to operate.

Moisture is the biggest challenge in managing RAP stockpiles. Excessive moisture not only increases the energy consumption of the drying process, but also affects the formulation accuracy of the recycled mix and reduces the bonding capacity of the recycled asphalt. Therefore, RAP stockpiles should be stored under tarp (tarpaulin) cover, in closed silos, or in sheds sheltered on three sides to minimize moisture absorption; at the same time, good drainage of the stockpile is required, even if the stockpile is covered, if placed on unpaved, poorly drained ground, it may also absorb moisture from the ground, so ideally, the RAP stockpile should be stored in the paved, sloped ground, and the water should be drained out of the stockpile. Ensure that moisture can drain smoothly away from the bottom of the pile.

Large, disorganized RAP stockpiles make it more difficult to control the quality of the final mix. Different sources of RAP stockpiles, with varying binder grades and aggregate sizes, can lead to inconsistent recycled mix quality if stored together. The best practice is to store RAP material according to its size, using signage and physical barriers to separate different grades of material piles to prevent unintentional mixing; at the same time, the size of the pile should not be too large, small, standardized piles not only reduce the compaction problems caused by long-term stacking, but also facilitates the uniform mixing of the RAP material prior to production to ensure that the quality of the material is consistent. In addition, the stability of the quality of RAP material is crucial to the use of additives, if the pile quality fluctuations are too large, it will be difficult to predict the effect of regeneration agents and other additives in the final mix, graded storage can help companies develop a more accurate mix formula to ensure stable production quality.

Although the RAP material is stored in the outdoor recycled materials, but enterprises still need to try to prevent pollutants into the pile, common pollutants including soil, vegetation, other debris, etc., these impurities if into the production process, will reduce the quality of recycled mix, affecting the performance of the final pavement. Preventing pollution requires proactive preventive measures, such as storing RAP stockpiles on paved or dirt-free surfaces, away from active construction areas, to avoid debris mixing into the stockpile during the construction process; in the process of loading, transshipment, and dumping of RAP stockpiles, ensure that the operation is standardized and clean, to avoid mixing of impurities; and at the same time, inspect the RAP stockpile on a regular basis, and promptly remove foreign objects from the surface, to reduce the contamination from the source.

Even with graded storage and uniform mixing of RAP stock, its performance will naturally change over time. For example, long storage time, exposure to extreme weather, or mixing of RAP stock from different sources will lead to fluctuations in its performance. Therefore, when RAP stockpiles are stored for long periods of time, exposed to extreme weather, or blended from multiple sources of RAP stockpiles, they need to be tested regularly for binder content and performance, aggregate gradation, moisture content, etc. The development of standardized testing program can ensure the accuracy of the mixture formula, to facilitate the enterprise to take the initiative to adjust the type or amount of additives, to protect the quality of recycled mixes stable, but also timely detection of the quality of RAP materials, to avoid unqualified materials into the production process.

Long-term storage of RAP material, due to compaction, temperature changes, environmental exposure and other factors such as hardening, caking phenomenon, hardening and caking of RAP material is difficult to mix uniformly in the production process, which will lead to poor aggregate wrapping, binder distribution is not uniform, affecting the ease of mixing, while the caking of the material in the drying drum or mixing cylinder is not uniformly heated, which will lead to mixing is not sufficient, and ultimately affect the performance of the pavement. Therefore, it is necessary to standardize the handling and management of RAP material, avoid stacking too high a conical pile, to prevent the bottom of the pile from being over-compacted; the use of layered piles of material, to ensure that the pile of internal air circulation, smooth drainage; regular mixing, mixing or sieving of the RAP pile, to restore its ease of use, to prevent segregation and lumps, to ensure that the RAP material to meet the requirements of the recycling asphalt plant production. Special attention should be paid to the fact that the management quality of RAP pile directly affects the production efficiency of recycling asphalt plant and product quality, good pile management, can effectively improve equipment production efficiency, reduce energy consumption, product quality, is an important part of the asphalt recycling production process.

Bitumen smoke treatment system, the whole station package and dust collecting system, foam asphalt system (warm mixing system).

<30mg/Nm³ (Bag house dust filter)

30%-50%

Mixer Capacity(kg/batch): 1500,2000,2500,3000,3500,4000,4500,5000.

Aggregate: 0.5% Powder: 0.3% Asphalt: 0.2% Recycled material: 0.5% Additive: 0.2%