PRODUCT INTRODUCTION

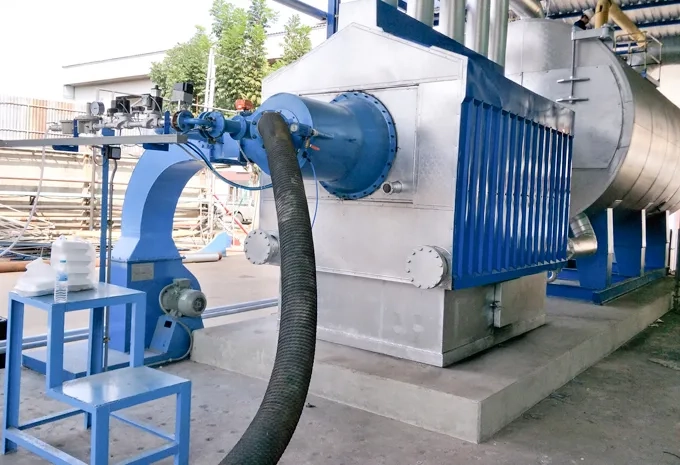

Pulverized Coal Burner for Boiler

Mechanism of Pulverized Coal Burner

The combustion characteristics of the multi-duct dense-thin swirl pulverized coal burner are: Separation of dense and thin: stable combustion effect, not easy to flame out, suitable for types of coal; Compound swirl: strengthen combustion and full burning; Wind-coated pulverized coal: anti-slagging, protecting the furnace bricks; Adjustable flame: The length and thickness of the flame can be adjusted as requirements to achieve the desired flame shape. This kind of burner is designed to achieve five effects of high efficiency, stable combustion, low pollution, anti slagging and anti high temperature corrosion. It can overcome the defects such as unstable combustion in the chamber, less adaptation of coal, serious slagging, high pollution, vulnerability of the brick and so on.

The Advantages of Multi-duct Dense-thin Swirl Pulverized Coal Burner

First, the coal can be used instead of oil, then fuel cost is saved and operating cost is reduced greatly.

Second, due to the special structure and reasonable air duct layout in the chamber, the pulverized coal can be stably and fully burned, and no ash residue is accumulated.

Third, due to the interaction between the primary wind dense-thin swirl and the regulation of the direct wind, the combustion is not only high efficient and stable but also adaptable to various coals from low volatile to high volatile.

Fourth, convenient online adjustment: according to the different coal quality and the structural characteristics of boiler furnace, the flame length, diameter, strength and weakness can be randomly adjusted, and the adjustment range is large.

The Main Features of New Multi-duct Pulverized Coal Burner

Adopt the most advanced pulverized coal combustion technology, the ablation and erosion to the combustion chamber’s inner wall by the flame are reduced. So there is almost no slag on the inner wall of the combustion chamber. Occasionally, the thickness of the slag in individual parts is only 1-2 mm. There is no adverse effect on the combustion and the life of the machine.

The inside of the combustion chamber adopts a special structure, the air duct is arranged reasonably, and the proportion of air distribution is appropriate. The pulverized coal flame can continue to burn stably in the combustion chamber, with sufficient combustion and high thermal efficiency.

The damper can be adjusted steplessly remotely. The flame length and thickness can be adjusted in real time in the control room according to the actual working conditions to achieve the best heating effect.

The combustion chamber is made of heat-resistant steel. It does not use any fragile materials such as refractory bricks or refractory castables. Its service life is several times than conventional burners lined with refractory bricks. It requires almost no maintenance during daily use.

New type multiple duct coal burner is made up of coal burner, coal powder storage system, Automatic Control System and accessory. It has the following features compared with similar product.

1. Slight slag formation and easy maintenance

The burner adopted the most advanced "semi-open pulverized coal combustion" combustion form.The pulverized coal flame is fully burned under the outer duct air package, which reduces the ablation and scour of the inner wall of the combustion chamber by the flame, and the slagging on the inner wall is only 1-2mm thick.

2. Full combustion with high thermal efficiency

Special structure is adopted in the combustion chamber, and the air duct layout is reasonable. The proportion of each air duct to the air is calculated scientifically. Pulverized coal airflow forms a large reflux area in the combustion chamber, which is easy to ignite and burn stably.

3. Flame shape is adjustable and heating effect is good

The damper is controlled by an intelligent valve controller, which can be adjusted remotely according to the combustion requirements, so as to keep the ratio of wind-coal at an appropriate ratio and achieve the best combustion effect. At the same time, the flame length and thickness can also be controlled remotely to adapt to different drying cylinder combustion zone and improve heating efficiency.

4. High reliability and long service life

The combustion chamber is made of imported heat-resistant steel, no longer using any firebrick or refractory castable materials and other vulnerable materials, and the special internal air duct layout facilitates the slag formation of the combustion chamber inner wall is only 1-2mm thick, the service life of the whole machine is several times than the traditional burner with firebrick lining, almost no need for maintenance in daily use.

5. High level of automation

There are two options for the new type coal burner.

Basic type: the damper and coal feeding are manually adjusted through the operation panel in the control room

Automatic type: Adopt "PC+PLC" mode control, according to the setting temperature can automatically adjust the coal powder supply, air distribution and other main parameters affecting the combustion effect, so as to accurately control the asphalt mixing station discharge temperature within the range of construction specifications.