In the wave of China’s global rise in manufacturing, asphalt mixing plants have become one of China’s leading export products. With technological innovation, production capacity advantages, and high cost-effectiveness, Chinese asphalt mixing plants not only meet the country’s massive infrastructure needs but are also in high demand across global markets such as Asia, Africa, and the Middle East. However, cross-border procurement is not a simple “order-delivery” process; it requires professional expertise to mitigate risks and maximize value. This article will provide a detailed overview of the key considerations when purchasing asphalt mixing plants from China, helping you make efficient procurement decisions.

Why choose to purchase asphalt mixing plants from China?

China’s emergence as a leading global supplier of asphalt mixing plants is no coincidence. Its core advantages are evident in the following areas:

Outstanding cost-effectiveness and budget-friendly

Chinese manufacturers leverage mature supply chains and economies of scale to control costs while maintaining quality. For small and medium-sized construction companies with limited budgets or buyers in emerging markets, Chinese equipment offers the possibility of ‘low-cost access to high-quality production’, resulting in shorter investment payback periods.

Rapid technological iteration and comprehensive functionality

In recent years, China’s asphalt mixing plant technology has undergone continuous upgrades, transitioning from ‘simple replication’ to ‘independent innovation’. Today’s equipment is universally equipped with intelligent control systems, energy-efficient heating devices, and advanced dust removal technology. Some models even incorporate artificial intelligence to optimize mixing processes, ensuring stable asphalt quality and minimizing raw material waste.

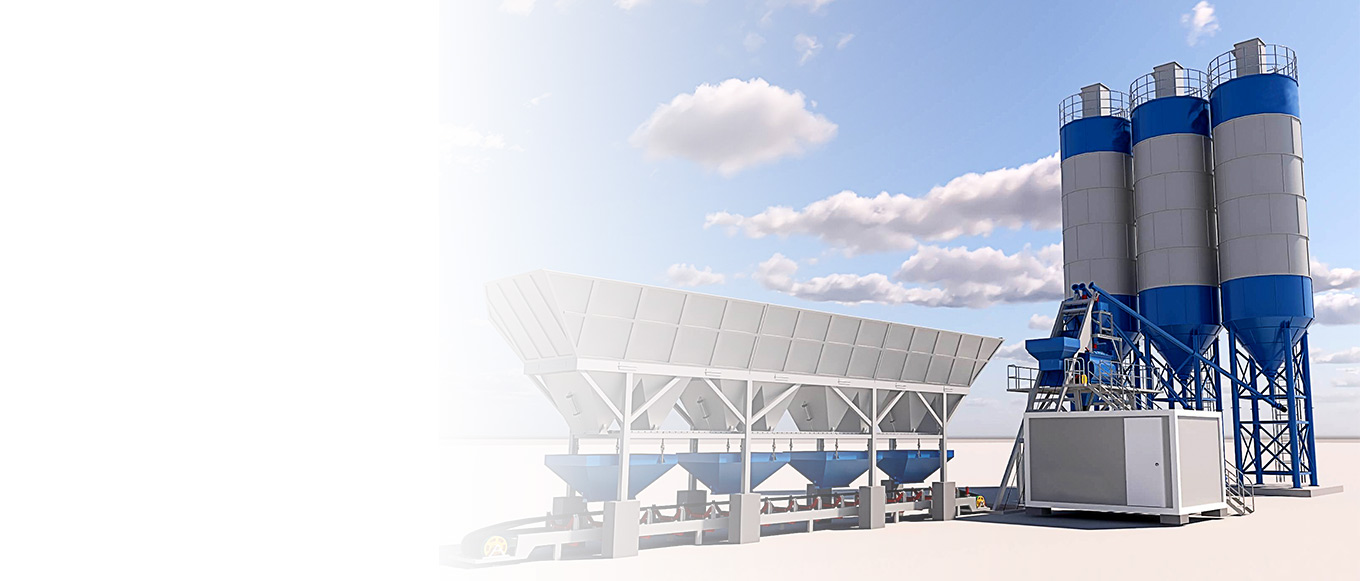

Diverse product types and broad application scenarios

Whether you need a mobile mixing plant for small-scale road repairs or a large-scale fixed mixing plant for highway construction, Chinese manufacturers can provide customized solutions. Common types include batch-type mixing plants (precision control of mix ratios), continuous-type mixing plants (high-output capacity), and mobile asphalt mixing plants (flexible relocation), covering all application scenarios from micro-scale to large-scale projects.

Global after-sales network is gradually improving

To enhance international competitiveness, leading manufacturers have established service centers or authorized dealers overseas to provide technical support, spare parts supply, and maintenance services. This addresses the pain point of ‘difficult maintenance after cross-border procurement,’ giving buyers peace of mind.

Tips for buying asphalt plants from China

Must-do before purchasing: clarify your own needs

Before contacting suppliers, clearly defining your needs is the key to avoiding “blind purchasing.” You can sort out your needs from the following dimensions:

Clarify production capacity requirements

Calculate the daily/monthly asphalt consumption based on the project scale: small road repairs may only require a production capacity of less than 50 tons per hour, while highway construction requires large equipment with a production capacity of more than 100 tons per hour. Insufficient capacity can delay project schedules, while excess capacity leads to financial waste.

Determine Equipment Type

Fixed-type mixing plants: Suitable for long-term production at fixed sites, offering high capacity and stability, ideal for large-scale infrastructure projects.

Mobile mixing plants: Equipped with towing devices, enabling quick relocation, suitable for remote areas or small-to-medium-sized projects requiring multiple site transitions.

Batch-type / Continuous-type: Batch-type is suitable for projects requiring high mixing ratio accuracy (e.g., municipal roads), while continuous-type is suitable for high-capacity, continuous operation scenarios (e.g., highways).

Focus on core functional requirements

For example: Is environmental compliance required (low emissions, low noise)? Is an intelligent remote monitoring system needed? Is compatibility with recycled material processing required? Listing these requirements can help quickly screen and identify suitable suppliers.

Selecting reliable manufacturers: avoiding the ‘low-price trap’

There are numerous asphalt mixing plant manufacturers in the Chinese market, but their quality and service vary greatly. How can you identify high-quality suppliers?

Prioritize experienced companies

Years in operation and production scale are important reference indicators. Generally, manufacturers with over 10 years of operation have stronger technical expertise and quality control capabilities. You can conduct an initial screening through their official websites, industry exhibitions (such as the Shanghai Bauma Exhibition), or third-party platforms (such as Made-in-China).

Verify qualifications and certifications

Legitimate manufacturers should hold ISO 9001 quality management system certification. Some export equipment may also need to comply with target market certifications such as EU CE or African SONCAP. Request suppliers to provide certification documents to avoid purchasing ‘counterfeit products.’

Refer to user reviews and case studies

Review platform comments and industry forum feedback, focusing on other buyers’ evaluations of equipment quality and after-sales response speed.

Request suppliers to provide case studies of similar projects. Ideally, contact overseas clients for on-site inspections of equipment operation to understand actual usage experiences.

Strictly control quality: Details determine equipment lifespan

Asphalt mixing plants are high-investment, long-term use equipment, and quality directly impacts production efficiency and safety. Quality assessment can be approached from the following angles:

Request detailed technical specifications

Clarify the brands of core components (e.g., motors from ABB or Siemens, burners from Liyalu), and inquire about the materials of critical structural components (e.g., whether the mixing drum uses wear-resistant steel plates). These details directly determine equipment lifespan.

On-site inspection or video factory verification

If possible, visit the factory production line to observe manufacturing processes and quality control procedures; if on-site visits are not feasible, request suppliers to provide videos of workshop operations and testing procedures to avoid falling into the trap of “shell companies.”

Confirm warranty scope and duration

High-quality manufacturers typically offer a 1-2 year warranty for the entire machine, with longer warranties for core components. It is essential to clarify the types of faults covered by the warranty (e.g., design defects, component damage) and the response time for repairs.

Calculate the total cost: more than just the ‘equipment quotation’

The cost of purchasing an asphalt mixing plant is much more than just the equipment itself. The entire chain of costs must be taken into account:

Clarify what is included in the quotation

Confirm whether the quotation includes core components, wear parts, installation tools, etc., to avoid having to purchase them at a higher price later.

Calculate Additional Costs

Transportation costs: Sea freight is the mainstream option (low cost but long lead time). Confirm the port, freight charges, and insurance costs.

Import taxes and duties: Calculate based on the target country’s tariff policies. Some countries offer preferential tax rates for Chinese equipment; consult customs in advance.

Installation and training: Large-scale equipment requires professional teams for installation. Confirm whether the supplier provides installation guidance or paid installation services.

Negotiate flexible payment terms

The common payment ratio is ‘30% advance payment + 70% paid before shipment’ but negotiation is possible: e.g., 50% advance payment + 40% paid after acceptance + 10% quality assurance deposit (paid in full after one year) to reduce financial risk.

After-sales service and spare parts: Ensure long-term stable operation

Equipment delivery is not the end; comprehensive after-sales support is essential to ensure long-term efficient production. Before purchasing, clarify the following:

After-sales network coverage

Inquire whether the supplier has service points or partner service providers in the target country to ensure timely on-site repairs in case of malfunctions.

Spare parts supply capability

Request the supplier to provide a list of commonly used spare parts and their prices, confirm spare parts inventory and delivery cycles to avoid downtime due to part shortages.

Training Services

Equipment operation and maintenance require specialized knowledge. Confirm whether the supplier provides operator training (on-site or online) and provides detailed operating manuals and maintenance guidelines.

Compliance and Logistics: avoiding customs clearance delays

Cross-border procurement must comply with import and export regulations, otherwise delivery may be delayed:

Understand the import regulations of the destination country

Confirm in advance the import requirements of the destination country for asphalt mixing plants, such as whether an import license, energy efficiency certification, or environmental testing report is required, and have the supplier assist in preparing the necessary compliance documents.

Choose a professional logistics partner

For large equipment transportation, engage a freight forwarder with experience in heavy machinery transportation. Confirm the transportation route, loading/unloading plans, and port coordination details to prevent equipment damage during transit.

Contract Signing: clarify responsibilities and avoid disputes

A contract is crucial for protecting both parties’ interests and must include the following core terms:

Equipment model, parameters, and configuration list (with drawings or photos);

Price details (including taxes, fees, and freight costs) and payment milestones;

Delivery timeline, acceptance criteria (e.g., trial operation capacity meets standards);

Warranty scope, duration, and after-sales responsibilities;

Breach of contract penalties (e.g., delayed delivery, quality non-compliance);

Dispute resolution methods (e.g., arbitration location in China or the destination country).

It is recommended to have a professional lawyer review the contract to ensure terms are clear and unambiguous.

Conclusion: rational procurement for mutual benefit

Purchasing an asphalt mixing plant from China is a cost-effective choice, but thorough preparation is essential: clarify requirements, select reliable suppliers, strictly control quality, calculate costs, and ensure comprehensive after-sales support. Through scientific planning, you can not only acquire suitable equipment but also establish long-term partnerships, laying the groundwork for a reliable supply chain for future projects. We hope the tips in this article will help you successfully embark on your cross-border procurement journey, with Chinese equipment ensuring the success of your projects.