Why choose a mobile asphalt mixing plant?

In engineering fields such as highway construction, municipal renovation, airport runway paving, and emergency repairs, the flexibility and efficiency of asphalt mixing plants directly affect project progress and cost control. Traditional stationary asphalt mixing plants are limited by fixed sites, complex foundation construction, and difficulties in relocation, making them unsuitable for the core needs of modern engineering projects, which require “multi-project linkage, rapid deployment, and flexible adjustment.”

Mobile asphalt mixing plants, with their core advantages of “immediate production upon installation, flexible relocation, and strong spatial adaptability,” have become the preferred solution for construction companies. Whether it’s rural road reconstruction with frequent site changes, urban road construction with limited space, or emergency maintenance projects with tight deadlines, they can complete asphalt mixture production in a low-cost and high-efficiency manner, helping companies shorten preparation cycles, reduce operating costs, and enhance project competitiveness. Choosing a mobile asphalt mixing plant means choosing an intelligent solution that fits the pace of modern engineering projects.

Advantages of Mobile Asphalt Mixing Plants

High mobility and rapid relocation

Featuring a modular design and trailer-mounted structure, it can be transported as a whole or in modules without complex disassembly, making it suitable for cross-regional and multi-site collaborative construction projects. No additional disassembly of core components is required during relocation, significantly reducing equipment downtime, making it particularly suitable for projects involving simultaneous construction of multiple lines or emergency repairs.

No basic installation required, saving time and costs.

No large concrete foundations are required; simply leveling the site is sufficient for operation, saving manpower, materials, and time costs associated with foundation construction. Small equipment can be installed and commissioned within 7-10 days of arrival, while medium and large equipment require only about 15 days, achieving “production upon arrival.”

Small footprint, suitable for various construction scenarios

Its compact design allows it to occupy only 1/3 to 1/2 the space of traditional fixed equipment, enabling flexible deployment in complex environments such as city centers, mountain roads, and narrow spaces. It can be efficiently adapted to various scenarios, including urban branch road renovation, mountain highway construction, and space-constrained environments such as ports and airports.

Modular design facilitates transportation and assembly.

The core components are all manufactured using modular technology, resulting in lightweight and compact designs that require fewer vehicles for transportation, thus reducing logistics costs. Assembly does not require specialized large equipment; it can be completed manually with simple tools, further enhancing construction convenience.

Comparison between mobile asphalt mixing plants and stationary asphalt mixing plants

Mobility comparison: Mobile units do not require a fixed foundation

- Mobile: Adopting a trailer or modular design, it has no fixed foundation requirements. When moving to a new site, it only requires simple disassembly of connecting parts and can be quickly transferred to a new construction site.

- Fixed type: Requires a permanent concrete foundation, cannot be moved, and is only suitable for single long-term projects.

Installation time comparison: Mobile units can be put into production in just a few days.

- Mobile: Installation and commissioning cycle for small equipment is 7-10 days, and for medium and large equipment it is 15-20 days, with no need to wait for basic maintenance.

- Fixed type: The foundation construction and equipment installation cycle takes 30-45 days, and the foundation maintenance requires additional time, resulting in a long preparation period.

Comparison of applicable scenarios: Mobile devices are more suitable for projects with frequent location changes.

- Mobile: Suitable for scenarios that require frequent relocation, such as rural road reconstruction, cross-regional maintenance, emergency repairs, and small-scale municipal engineering projects.

- Fixed type: Suitable for large-scale production in single fixed sites such as large highways and long-term building material production bases.

Investment cost comparison: Mobile initial investment is more flexible

- Mobile: No infrastructure investment is required, equipment models can be flexibly selected according to the scale of the project, the initial capital pressure is small, and the investment return cycle is short.

- Fixed type: High infrastructure costs, fixed equipment models, large initial investment, suitable for long-term large-scale production scenarios.

Comparison of production efficiency and quality: Both can produce high-quality asphalt mixtures.

- Mobile type: Utilizing precise metering and forced mixing technology, combined with international brand sensors and control systems, the quality of the mixture meets the high standards of highway construction.

- Fixed type: has a larger production capacity, but mobile type can also achieve a high production capacity of 320t/h through modular upgrades to meet the needs of medium and large projects.

Choosing the Right Type of Mobile Asphalt Mixing Plant: Which One is Best for Your Project?

1. Batch Mix Asphalt Mixing Plant

Employing a “batch mixing” model, each batch completes the entire process of aggregate screening, metering, and mixing, resulting in precise mix proportions and stable quality. Suitable for projects with high asphalt quality requirements, such as highways, airport runways, and municipal main roads.

2. Continuous mobile asphalt mixing plant

Employing a “continuous mixing” design, aggregate drying, heating, and asphalt mixing are carried out simultaneously, resulting in high production efficiency and a streamlined process. It is suitable for projects with high capacity requirements but not requiring ultra-high precision mix proportions, such as highway maintenance, rural roads, and temporary construction.

Recommended small-scale projects: Super Mobile Batch Mix Plant with a capacity of 40-90t/h

Suitable for rural roads, community roads, small-scale municipal renovation projects, etc., with frequent relocation and limited space, the equipment is highly integrated and the single chassis design allows for quick relocation without additional assembly.Continuous Asphalt Mixing Plant

Recommended for medium to large-scale projects: Mobile Asphalt Mixing Plant with a capacity of 60-320t/h

It is suitable for medium and large-scale projects such as highway branch lines, urban main roads, and airport auxiliary roads. Its production capacity is flexible and adjustable, the quality of the mixture is stable, and it supports long-term joint construction of multiple projects.

Recommended highway maintenance project: Continuous Asphalt Mixing Plant

Suitable for routine highway maintenance, emergency repairs, pothole filling, and other projects, it boasts high continuous production efficiency and an integrated trailer design that allows for rapid on-site arrival and immediate production.

Zoomline Mobile Asphalt Mixing Plant Product Classification and Recommendations

Product Features and Advantages

- Modular design, easy installation and relocation, no need for traditional foundation engineering, saving time and costs.

- Using TOLEDO weighing sensors and a three-dimensional mixing agitator, the proportions are precise and the quality of the mixture is high.

- With excellent environmental performance, the bag filter emits less than 20mg/Nm³, meeting global environmental standards.

- German SIEMENS electrical components and Japanese OMRON PLC control systems operate stably under harsh conditions.

| model | Production capacity (t/h) | Cold aggregate bin capacity | Drying drum dimensions (mm) | Mixer capacity (kg) | Total power (kW) | Finished product silo (optional) |

| ZAP-M60 | 60 | 4×4.5m³ | 1500×6000 | 800 | ≈185 | 15 tons |

| ZAP-M80 | 80 | 4×6.5m³ | 1500×6600 | 1000 | ≈270 | 30 tons |

| ZAP-M100 | 100 | 4×6.5m³ | 1500×6600 | 1300 | ≈300 | 30 tons |

| ZAP-M120 | 120 | 4×8m³ | 1800×8000 | 1500 | ≈390 | 30 tons |

| ZAP-M160 | 160 | 5×8m³ | 1950×9000 | 2000 | ≈500 | 60 tons |

| ZAP-M200 | 200 | 5×12m³ | 2200×9000 | 2500 | ≈570 | 100 tons |

| ZAP-M240 | 240 | 5×12m³ | 2400×9000 | 3000 | ≈640 | 100 tons |

| ZAP-M320 | 320 | 5×15m³ | 2600×9000 | 4000 | ≈800 | 100/200 tons |

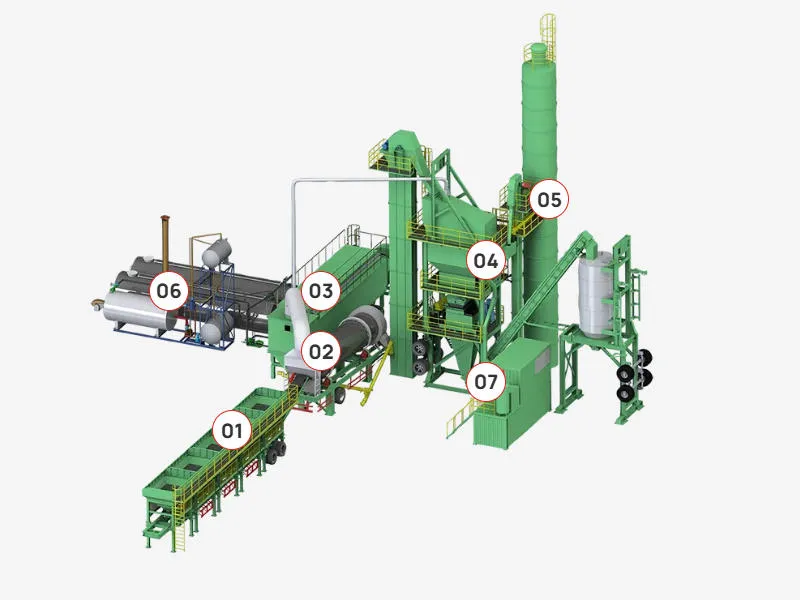

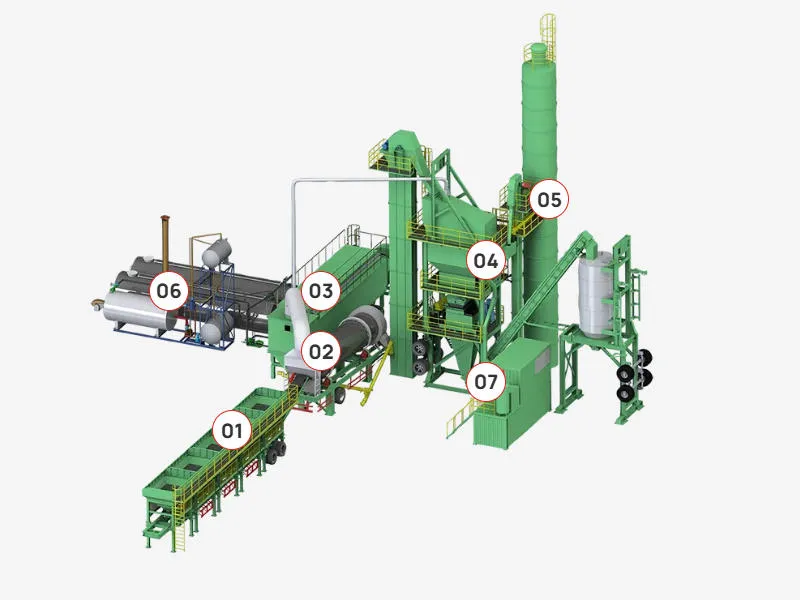

- 01 Mobile aggregate bins: Designed with 4-5 bins, equipped with a material shortage alarm and vibrator to prevent material blockage.

- 02 Moving drying drum: Optimized blade structure, heating efficiency increased by 30%, and cooling time shortened.

- 03 Mobile bag filter: Uses DuPont NOMEX filter bags, emissions <20mg/Nm³, meeting environmental standards.

- 04 Mobile Mixing Tower: Integrates screening, metering, and mixing functions, with optimized vibration frequency and high screening efficiency.

- Mobile filling bin: Precise material supply, combined with a weighing system to ensure accurate proportioning.

- 06 Mobile Asphalt Tank: Supports multi-fuel heating and has excellent heat preservation performance.

- Mobility Control System: Multilingual compatible, supports remote diagnostics and automated operation.

Features

- Adopting the Korean DMI structural design, it is highly mobile, occupies a small area, and has a short downtime for relocation.

- The aviation plug allows for quick connection and easy wire removal and installation, increasing installation efficiency by 50%.

- The German-engineered mixer, paired with a NORD reducer, ensures high mixing uniformity and stable operation.

- The process is fully automated, requiring no manual intervention throughout the drying, weighing, mixing, and unloading stages.

| model | Production capacity (t/h) | Cold aggregate bin capacity | Drying drum dimensions (mm) | Mixer capacity (kg) | Dust removal filtration area (m²) | Asphalt tank capacity (optional) |

| ZAP-M60T | 60 | 4×4.5m³ | 1300×6000 | 800 | 300 | 30-80m³ |

| ZAP-M80T | 80 | 4×6.5m³ | 1500×6600 | 1000 | 380 | 30-80m³ |

| ZAP-M100T | 100 | 4×6.5m³ | 1500×6600 | 1300 | 400 | 30-80m³ |

| ZAP-M120T | 120 | 4×8m³ | 1800×8000 | 1500 | 500 | 30-80m³ |

| ZAP-M160T | 160 | 5×8m³ | 1950×9000 | 2000 | 550 | 30-80m³ |

| ZAP-M200T | 200 | 5×8m³ | 2200×9000 | 2500 | 650 | 30-80m³ |

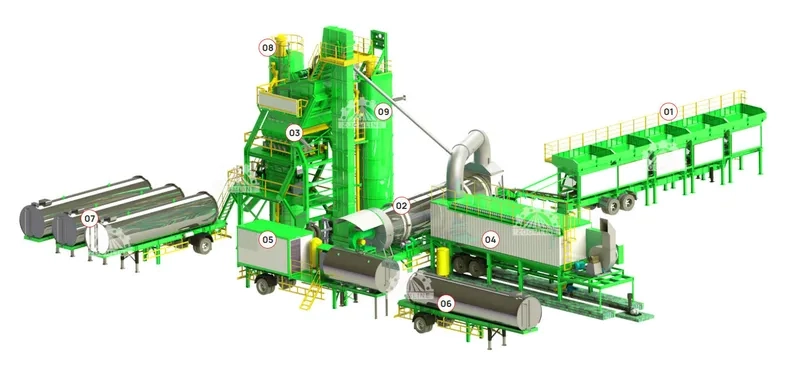

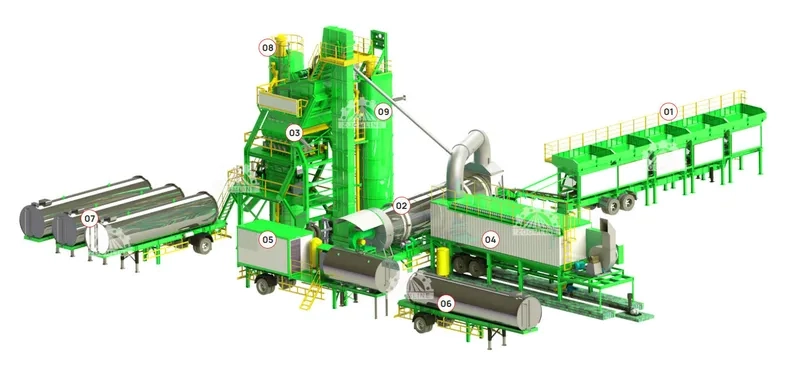

- 01 Mobile cold aggregate supply system: The silo and aggregate belt are integrated on the same chassis, ensuring stable operation.

- 02 Mobile Drying Drum + Burner: Driven by four friction wheels, low noise, and supports multiple fuel selection.

- 03 Mobile mixing tower: Integrated design of vibrating screen, hot aggregate bin and weighing hopper.

- 04 Mobile dust collector: Two-stage dust removal, the collected dust can be recycled.

- 05 Mobile Control Room: 4.5-6m control room, equipped with sound and heat insulation design.

- 06 Diesel storage tank: Integrated with the control room chassis, with a compact layout.

- 07 Mobile Asphalt Storage Tank: Multiple heating methods are available to suit different working conditions.

- Packing bin: 30m³ standard capacity, expandable.

- 09 Recycled packing bin: Dust is recycled and reused, reducing raw material consumption.

Features

- The single-chassis highly integrated design integrates functions such as cold aggregate processing, drying, screening, metering, and mixing.

- Cable installation and commissioning are completed before leaving the factory. During relocation, only the cables between the frames need to be connected, and no secondary assembly is required.

- The semi-trailer design is compatible with international standard 50#/90# trailer couplers and can be used for highway transportation.

- It supports customized configurations, and the number of aggregate bins, dust removal methods, and fuel types can all be flexibly selected.

| model | Production capacity (t/h) | Drying capacity (t/h) | Mixer capacity (kg) | Number of sieve layers | Asphalt tank heating method | control system |

| ZAP-M40E | 30-40 | 30-40 | 500 | 4 floors | Direct heating / hot oil heating / electric heating | PLC + PC + CCTV monitoring |

| ZAP-M60E | 50-60 | 50-60 | 800 | 4 floors | Direct heating / hot oil heating / electric heating | PLC + PC + CCTV monitoring |

| ZAP-M90E | 80-90 | 80-100 | 1300 | 4 floors | Direct heating / hot oil heating / electric heating | PLC + PC + CCTV monitoring |

- 01 Cold aggregate supply system: 3-6 feeders are available to suit different raw material requirements.

- 02 Drying System: High-efficiency burner, supporting multiple fuels including diesel, heavy oil, LNG, and coal.

- 03 Twin-shaft mixer: Mixes evenly, with minimal wear and a long service life.

- 04 Weighing system: accurately measures aggregates, asphalt, and fillers to ensure accurate proportioning.

- 05 Vibrating screen: 4-layer design, high screening efficiency, suitable for aggregates of different particle sizes.

- 06 Burner: Featuring international brand components, high combustion efficiency, and low emissions.

- 07 Dust Collector: Gravity + bag filter two-stage dust collection, meeting environmental protection standards.

- 08 Asphalt Tank: Horizontal/vertical models available, with excellent thermal insulation performance.

- 09 Diesel/Heavy Oil Storage Tank: Integrated with the chassis for convenient transportation.

Features

- The continuous hybrid design increases production efficiency by 30% compared to intermittent methods, making it suitable for large-scale continuous construction.

- The integrated trailer structure allows a single trailer to complete all transportation functions, resulting in low relocation costs.

- No foundation construction is required; it can be quickly fixed on-site and put into production, shortening the installation cycle to within 7 days.

- It is compatible with both portable and stationary modes, and can be used for both highway maintenance and long-term production.

| model | Rated capacity (t/h) | Total power (kW) | Drying drum dimensions (mm) | Dust removal filtration area (m²) | Finished product silo capacity (m³) | Asphalt temperature (°C) |

| ZAP-C20M | 20 | 50 | ∅1.2×3.8 | 115 | 1.5 (optional 7.5/20) | 130-160 |

| ZAP-C40M | 40 | 69 | ∅1.2×5.3 | 150 | 1.5 (optional 7.5/20) | 130-160 |

| ZAP-C60M | 60 | 110 | ∅1.5×7 | 210 | 1.5 (optional 7.5/20) | 130-160 |

| ZAP-C80M | 80 | 150 | ∅1.5×8 | 260 | 1.5 (optional 7.5/20) | 130-160 |

| ZAP-C120M | 120 | 210 | ∅1.8×8.5 | 350 | 1.5 (optional 7.5/20) | 130-160 |

| ZAP-C160M | 160 | 210 | ∅1.95×8.5 | 400 | 1.5 (optional 7.5/20) | 130-160 |

| ZAP-C200M | 200 | 240 | ∅2.2×8.5 | 450 | 1.5 (optional 7.5/20) | 130-160 |

- 01 Cold aggregate supply system: silo capacity 4.5-8m³, adaptable to different production capacity requirements.

- 02 Drying System: Optimized drum structure, high drying efficiency, fuel consumption ≤7kg/t.

- 03 Elevator: Efficiently conveys aggregates, operates stably, and has low noise.

- 04 Oil Tank: Integrated with the chassis, convenient for transportation, and flexible in heating methods.

- 05 Asphalt Tank: Supports electric heating, heat transfer oil heating, and direct heating, with good heat preservation effect.

- 06 Bag filter: Filtration area 115-450m², emissions meet standards, water dust removal optional.

- 07 Control System: Supports manual/automatic switching, simple operation, and real-time data monitoring.

Detailed Explanation of the Main Components of a Mobile Asphalt Mixing Plant

Cold Aggregate Feeding System

- It is equipped with 4-6 independent silos with a capacity of 4.5-15m³ to meet the storage needs of different raw materials.

- The belt feeder uses frequency conversion speed regulation, which has a wide speed range, uniform material feeding, and high working efficiency.

- Each discharge port is equipped with a material shortage alarm device, and vibrators are installed on the silo walls to prevent raw materials from arching or clogging.

- A screen is installed on the top of the silo to prevent large-diameter materials from entering and to protect the operation of subsequent equipment.

Drying System

- Drying drum: Optimized blade geometry improves heating efficiency by 30%, resulting in lower surface temperature and shorter cooling time.

- Burner: Optional Italian brand high-efficiency burner, supporting multiple fuels such as diesel, heavy oil, natural gas, and coal.

- Temperature control: The Honeywell intelligent temperature control system is used to precisely control the aggregate heating temperature to 160℃.

- Insulation design: The drum uses composite insulation materials to reduce heat loss and lower fuel consumption.

Elevator and Screening System

- Elevator: Efficiently transports heated aggregates, operates stably, and has a low failure rate.

- Vibrating screen: 4-5 layer design, optimized vibration frequency and amplitude, high screening efficiency, suitable for aggregates of different particle sizes.

- Screen material: wear-resistant and corrosion-resistant, long service life, and easy to replace.

- Hot aggregate bins: These bins store aggregates of different sizes to prepare for accurate metering.

Mixing Tower

- Metering system: Employs TOLEDO weighing sensors to measure aggregates, asphalt, and fillers separately with high accuracy.

- Mixer: Three-dimensional mixing design, long arm and short shaft + bidirectional mixing blades, resulting in high mixing uniformity.

- Asphalt spraying: Pressurized asphalt pumps spray at multiple points to ensure that asphalt evenly covers the aggregate.

- Mixing cycle: intermittent mixing is uniformly 45 seconds per batch, while continuous real-time mixing is highly efficient.

Dust Collecting System

- Two-stage dust collection: Gravity primary dust collection + bag secondary dust collection, dust collection efficiency >99%.

- Filter bags: Made with DuPont NOMEX filter bags from the USA, which are heat-resistant, have a long service life, and can be replaced without special tools.

- Intelligent protection: The cooling valve automatically opens to cool the filter bags when the temperature exceeds the limit, preventing damage to the filter bags.

- Emissions: Dust emissions <20mg/Nm³, in compliance with global environmental standards.

Asphalt Storage Tank

- Asphalt tanks: Capacities of 30-80m³ are available, and horizontal/vertical designs are supported to suit different sites.

- Heating methods: Electric heating, heat transfer oil heating, and direct heating are available to meet different working conditions.

- Thermal insulation performance: The tank wall is made of thermal insulation material to reduce heat loss and maintain stable asphalt temperature.

- Supply system: The pressure pump provides precise material supply, ensuring accurate asphalt metering and effective spraying.

Control system

- Core components: Uses German SIEMENS electrical components, Japanese OMRON PLC and touch screen, ensuring stable operation.

- Features: Automatic data recording, real-time monitoring, fault alarm, and support for multiple language switching.

- Remote diagnostics: Global remote automatic detection function for rapid response to equipment failures.

- Protection rating: IP55 protection control cabinet, adaptable to harsh construction environments, containerized control room with sound and heat insulation.

Finished material storage

- Capacity options: 15-200 tons available to suit different production capacities and construction schedules.

- Installation method: Side-mounted or bottom-mounted design, flexibly adaptable to site layout.

- Thermal insulation function: The silo is equipped with an insulation layer to maintain the temperature of the finished asphalt and prevent clumping.

- Unloading design: Rapid unloading reduces waiting time and improves construction efficiency.

Production Process of Mobile Asphalt Mixing Plant

Cold aggregate feeding and conveying

- Cold aggregate is fed into each bin by a loader, and the feed rate is precisely controlled by a frequency converter belt feeder according to the formula requirements.

- The aggregate is conveyed to the drying drum by a conveyor belt, and large-diameter impurities are filtered out by a screen during the conveying process.

Aggregate drying and heating

- After the aggregate enters the drying drum, it comes into full contact with the high-temperature airflow generated by the burner, and the moisture evaporates quickly.

- The temperature control system monitors the temperature inside the drum in real time to ensure that the aggregate is heated to the ideal temperature of about 160°C.

Sieving, Metering and Forced Mixing

- The heated aggregate is fed into a vibrating screen via an elevator, and after being screened into different particle sizes, it is stored in a hot aggregate bin.

- According to the preset formula, the weighing system measures the aggregate, asphalt, and filler separately and feeds them into the mixer in sequence.

- The mixer uses bidirectional blades to force mixing, and the asphalt is sprayed at multiple points to evenly cover the aggregate, forming a high-quality mixture.

Finished asphalt mixture unloading and storage

- The mixed material is sent to the finished product silo for temporary storage through the unloading device, and the silo’s insulation layer maintains the temperature.

- According to construction needs, materials are unloaded from the silo into transport vehicles in an orderly manner and sent to the construction site.

Dust removal and environmental protection process

- Dust generated during the drying and mixing process is first collected by a gravity dust collector, and large particles of dust are recycled.

- Fine dust enters the bag filter and is filtered through the filter bags, with an emission concentration of <20mg/Nm³, which meets environmental protection requirements.

- The filtered dust can be recycled or discharged via a screw conveyor, achieving a win-win situation for environmental protection and resource utilization.

How to choose the best mobile asphalt mixing plant for your road project?

Select production capacity based on project scale.

- For small-scale projects (rural roads, community roads): choose a capacity of 30-90t/h, such as the ZAP-ME series super mobile intermittent type.

- Medium-sized projects (urban main roads, county roads): Select a capacity of 60-200t/h, such as the ZAP-MT series T-type mobile intermittent type.

- For large-scale projects (highways, airport runways): select a capacity of 200-320t/h, such as the ZAP-M320 standard mobile intermittent type.

Select the mobility type based on the frequency of the transfer.

- For frequent site relocations (multi-site coordination, emergency repairs): Choose the Super Mobile series (ZAP-ME, ZAP-CM), with a single chassis integrated design for rapid site relocation.

- For projects requiring frequent relocation (long-term construction on a single project): Choose the standard mobile series (ZAP-M, ZAP-MT), which offers stable production capacity and a wide range of configurations.

Select dust removal method according to environmental protection requirements.

- High environmental protection requirements (city center, scenic area): Choose a bag filter with emissions <20mg/Nm³, as standard on all Zoomline mobile series.

- Special operating conditions (high dust concentration): Water dust removal can be selected to further reduce emission concentration.

Select burner configuration based on fuel type.

- For standard operating conditions: Select a diesel/natural gas dual-fuel burner, suitable for most construction scenarios.

- Cost-sensitive: Choose heavy oil or coal burners to reduce fuel costs.

- Environmental protection first: Choose natural gas burners for cleaner emissions.

Optional configurations should be considered based on budget.

- Ample budget: Equipped with large-capacity finished product silos, a recycling system, and a remote monitoring module to improve efficiency and convenience.

- Limited budget: Choose the basic configuration to meet core production needs, with optional upgrades available later.

The Core Competitiveness of Zoomline Mobile Asphalt Mixing Plant

International quality parts

- Key components are sourced from internationally renowned brands, such as TOLEDO load cells, NORD gearboxes, SIEMENS electrical components, and OMRON PLCs.

- International standard components ensure low maintenance costs, long service life, and stable equipment operation.

Global success stories and export experiences

- Our products are exported to more than 80 countries, covering Europe, Africa, North America, Southeast Asia and other regions, and are adapted to different climates and construction environments.

- Successful projects include an 80t/h mobile mixing plant project in Bangladesh and a 320t/h large-scale project in Cambodia, gaining recognition from global clients.

Comprehensive after-sales service and remote diagnostics

- The product comes with a 15-month warranty, during which defective parts will be replaced free of charge and repair services will be provided.

- We offer 24/7 after-sales service, with technicians responding within one hour and resolving common faults within 24 hours.

- Global remote diagnostics capabilities allow for troubleshooting of most faults without requiring on-site visits, saving repair time.

- Lifetime technical support and preferential spare parts supply ensure long-term stable operation of equipment.

Excellent environmental performance

- Dust emissions are less than 20mg/Nm³, far below international environmental standards, meeting environmental requirements worldwide.

- Optimize the combustion system to reduce emissions of harmful gases such as NOx and SO₂, making it green and environmentally friendly.

- With its highly efficient and energy-saving design, fuel consumption is as low as 6-7 kg/t, saving 30% more energy than traditional equipment.

Conclusion: Contact Zoomline now for a quote on a mobile asphalt mixing plant.

By choosing Zoomline mobile asphalt mixing plants, you will receive customized solutions, fast delivery, and professional installation support, ensuring a worry-free project launch.

Our team will recommend the most suitable equipment models and configurations based on your project size, relocation needs, environmental standards, and budget, helping you reduce costs and improve efficiency.

Whether you need small emergency maintenance equipment or large-scale production equipment, Zoomline can provide high-quality, cost-effective mobile asphalt plant for sale.

Contact us now, fill out the inquiry form or call our hotline to get an accurate quote and technical solutions, and start your efficient road construction journey!