Why Asphalt Plants Close in Winter?

As a core pillar of the road construction industry, asphalt plants play a crucial role in producing asphalt mixtures. From urban highways to rural access roads, from large parking lots to airport runways, nearly all hard pavement construction relies on the materials they provide. However, in most temperate and cold regions worldwide, asphalt plants often cease operations during the winter season. This seasonal closure is not arbitrarily decided but rather a reasonable choice formed through comprehensive consideration of quality, efficiency, safety, and cost factors over the long-term development of the industry. To explore the underlying reasons, it is necessary to analyze from multiple angles, including the impact of climate on asphalt material performance, seasonal fluctuations in market demand, objective requirements for equipment maintenance, ensuring worker safety, and constraints imposed by environmental protection regulations.

Weather Limits

Cold Hurts Asphalt Work

Asphalt is a material highly sensitive to temperature, with its production and construction processes closely tied to temperature. The low temperatures of winter pose significant challenges for asphalt production. When temperatures drop below approximately 10 degrees Celsius, the physical properties of asphalt undergo noticeable changes. During production, low temperatures cause asphalt viscosity to increase significantly. Asphalt that can be easily mixed with aggregates at appropriate temperatures becomes difficult to stir, resulting in significantly reduced mixing efficiency and potential uneven mixing, directly affecting the quality of the asphalt mixture.

During construction, the impact of low temperatures is even more pronounced. After being transported from the factory to the construction site, asphalt mixtures cool rapidly due to low temperatures. This makes it difficult to spread and level the mixture during paving. Additionally, due to the rapid cooling, there is very limited time for rollers to perform compaction operations. Compaction is a critical step in ensuring the quality of asphalt pavements. Only through adequate compaction can the pavement achieve sufficient density, strength, and durability. However, at low temperatures, compaction is difficult to perform adequately, leading to high porosity in the pavement. This makes the pavement more susceptible to damage from rainwater erosion and vehicle crushing during subsequent use.

If the ground is frozen, the problem becomes even more severe. Frozen ground prevents asphalt from bonding tightly with the base layer. After paving, as temperatures fluctuate and the ground thaws, voids may form between the asphalt layer and the base layer, leading to issues such as pavement cracking and peeling, which may require repairs or rework in the short term.

Climate differences across regions also result in significant variations in asphalt plant operations during winter. In areas with mild winters where temperatures rarely drop below 10°C, such as tropical and subtropical regions, asphalt plants can generally operate and construct year-round. In severely cold northern regions where temperatures remain below freezing for extended periods, asphalt plants typically cease operations throughout the winter. In regions like Denver, where winter climates fall between the two extremes, there are cold periods with ground freezing and temperatures consistently below 4–10 degrees Celsius. However, there are also brief thawing periods when the ground thaws and temperatures rise. Asphalt plants may seize such opportunities for short-term production and construction, but these opportunities are unstable and cannot sustain continuous plant operations throughout the winter. Overall, asphalt production and construction require temperatures to remain above 13 degrees Celsius for several consecutive days, with nighttime temperatures not falling below freezing, to ensure that the asphalt mixture can undergo mixing, paving, and curing processes smoothly.

Snow and Rain Make It Harder

Precipitation events such as snowfall and rainfall, especially during winter, pose significant challenges for asphalt paving work. When temperatures drop to a certain level, precipitation may fall as snow, freezing rain, or ice, making asphalt paving unsuitable under such conditions. Ice and snow directly lower the temperature of the asphalt mixture, causing it to cool excessively before reaching the construction site, rendering it unable to be spread and compacted normally. Additionally, ice and snow covering the ground obstruct direct contact between the asphalt and the surface, impairing adhesion.

Even in relatively mild winter weather, rainfall can have adverse effects on asphalt paving. Rainwater can make the ground damp, and asphalt mixture laid on damp ground struggles to form good adhesion with the surface. Furthermore, rainwater can penetrate into the asphalt mixture, disrupting the curing and curing process of the asphalt, leading to reduced pavement strength. Furthermore, rainfall can cause the surface temperature of the asphalt mixture to drop rapidly, shortening its workable time and increasing construction difficulty.

Cold and damp weather conditions also increase the likelihood of quality issues in the pavement. For example, asphalt pavement laid in a wet state and exposed to low temperatures may experience ice expansion within the pavement structure, leading to cracks. At the same time, wet and cold environments prolong the curing time of asphalt. During this period, the pavement is more susceptible to damage from external factors, such as vehicle compaction and pedestrian traffic, thereby affecting the final quality of the pavement. Therefore, asphalt paving work is typically suspended when precipitation is forecast during winter, which also limits the operations of asphalt plants during winter to some extent.

Less Need in Winter

Fewer Road Projects

The reduction in winter road construction projects is a key factor contributing to the decline in asphalt demand. From a project planning perspective, government departments and construction contractors consider seasonal factors when developing construction schedules. Due to harsh winter weather conditions, asphalt pavement construction quality is difficult to guarantee, and construction costs significantly increase. Therefore, most road construction projects are scheduled for warmer seasons, with few new large-scale road construction projects initiated during winter.

For projects requiring long-term construction, contractors strive to complete major asphalt paving work before winter arrives or enter a hiatus phase. This is because continuing construction during winter not only poses quality issues due to low temperatures affecting asphalt materials but also leads to slow progress and increased safety risks caused by snow and ice conditions. For example, to ensure construction can proceed, measures such as heating the ground or removing snow and ice may be required, which would incur additional construction costs and may not yield ideal results.

Additionally, while traffic volume and travel demand persist in winter, road maintenance priorities shift toward snow removal and anti-slip measures to ensure road safety, with relatively fewer demands for new road construction or large-scale renovations. This further reduces the number of winter road construction projects.

Less Demand for Asphalt

Market demand for asphalt decreases significantly during winter. As mentioned earlier, the sharp decline in winter road construction projects directly leads to reduced demand for asphalt mixtures. Asphalt plants primarily produce to meet construction demand, and when market demand decreases, maintaining the original production scale can result in product inventory buildup.

Asphalt storage also requires certain conditions, including maintaining appropriate temperatures to prevent solidification. Energy consumption for asphalt storage is higher in winter. Additionally, long-term storage may adversely affect asphalt performance, making quality difficult to guarantee. Therefore, in response to declining market demand, asphalt plants may reduce production or even cease operations to avoid unnecessary costs and product waste.

From the perspective of market supply and demand dynamics, when demand decreases while supply remains constant, it may lead to a decline in asphalt prices, further impacting the economic efficiency of asphalt plants. Therefore, to adapt to seasonal fluctuations in market demand, asphalt plants choosing to shut down during winter is a business strategy aligned with market principles.

Equipment Maintenance and Operational Costs

Time to Fix Equipment

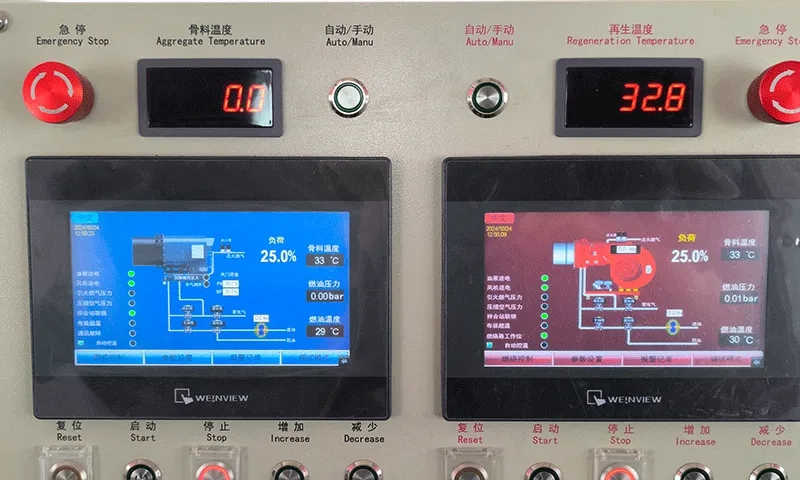

Asphalt plant equipment experiences varying degrees of wear and tear during prolonged operation, and winter provides an appropriate window of opportunity for maintenance. Asphalt production equipment, such as burners, dryers, and mixing equipment, requires continuous operation during production, particularly burners and dryers, which must heat aggregates and are exposed to high-temperature environments, leading to corrosion and wear of components.

During peak production seasons, equipment typically operates at full capacity to meet market demand, leaving little time for comprehensive and thorough maintenance and inspections. However, during winter when production tasks decrease or cease, plants can utilize this period to conduct thorough inspections, repairs, and maintenance on equipment. For example, burners can be inspected and worn components replaced to ensure combustion efficiency; dryers can be cleaned internally to remove residual impurities and debris, improving heating efficiency; and mixing equipment can be lubricated and calibrated to ensure uniform mixing.

Regular maintenance and inspections can promptly identify and resolve equipment issues, preventing equipment failures during peak production seasons that could disrupt production schedules. Additionally, maintained equipment can restore and enhance performance, providing reliable support for the following year’s production. Therefore, winter is the optimal time for asphalt plants to conduct equipment maintenance, which is also a key reason why asphalt plants shut down during winter.

Winter Runs Cost More

Winter operations significantly increase asphalt plant operational costs. In terms of energy consumption, more fuel is required to heat aggregates and asphalt to maintain the necessary production temperatures. Lower winter temperatures result in faster heat loss, leading to significantly higher energy consumption for heating equipment compared to other seasons. For example, dryers require more fuel in winter to heat aggregates to the required temperature, directly increasing production costs.

From the perspective of labor costs, the harsh winter construction environment requires providing workers with additional cold-weather gear, and may necessitate paying extra subsidies to attract workers to work in low-temperature conditions. Additionally, low temperatures can impair worker efficiency, leading to reduced production output per unit of time, which indirectly increases labor costs.

Furthermore, if operations continue during winter, additional funds must be invested in purchasing and maintaining snow removal equipment, insulation equipment, and other tools to cope with harsh weather conditions, all of which increase the factory’s operational costs. In a market with low demand, high operational costs further compress the profit margin of asphalt plants and may even lead to losses. Therefore, from a cost control perspective, choosing to shut down during winter is a reasonable decision for asphalt plants.

Worker Safety and Work Environment

Cold Is Dangerous

Low-temperature environments pose numerous safety hazards for workers. During winter asphalt production and construction, workers are exposed to low-temperature environments for extended periods, which can lead to various health issues. For example, low temperatures can impair blood circulation, increasing the risk of frostbite in extremities such as hands and feet. Prolonged exposure to cold conditions may also cause hypothermia, resulting in symptoms like fatigue and impaired consciousness, which can affect workers’ judgment and operational capabilities.

At construction sites, winter often brings snow and ice, making the ground slippery. Workers face a significantly increased risk of slipping and falling while walking or operating equipment, which may result in personal injury. Additionally, low-temperature environments can affect the normal operation of equipment. For instance, the lubrication system of equipment may malfunction in low temperatures, leading to unstable operation and increasing safety risks during equipment use.

To ensure worker safety, relevant safety regulations impose strict requirements and restrictions on winter construction. For example, construction companies are required to provide workers with appropriate cold-weather gear, install necessary safety warning signs, and promptly remove snow and ice from construction sites. However, even with these measures in place, winter construction safety risks remain higher than in other seasons. Therefore, reducing winter construction activities, including closing asphalt plants, is an important measure to mitigate safety hazards.

Cold Slows Work Down

Low-temperature environments can negatively impact workers’ work efficiency. Cold weather causes muscle contraction, slows down movements, and reduces reaction speeds, which can affect work quality and progress during tasks requiring precise operations such as asphalt paving and compaction. Workers in low-temperature environments must expend more physical energy to withstand the cold, leading to fatigue and reduced work enthusiasm and concentration.

From the perspective of labor supply, the harsh working conditions in winter may cause some workers to temporarily leave their positions in search of more comfortable work, leading to labor shortages for asphalt plants and construction teams. To ensure production and construction continue, companies may need to spend more time and resources on recruiting and training new workers, further impacting work efficiency.

Reduced work efficiency can lead to extended production cycles, delayed construction progress, and increased project costs. Therefore, from the perspective of improving work efficiency and ensuring construction progress, it is reasonable for asphalt plants to close during winter.

Environment Rules

Tighter Winter Rules

The production process at asphalt plants generates certain pollutant emissions, such as particulate matter, nitrogen oxides, and volatile organic compounds, which can have an impact on air quality. To protect the environment and public health, countries and regions have established corresponding environmental protection regulations to strictly limit emissions from asphalt plants.

During winter, due to meteorological conditions such as temperature inversions, poor air circulation, and difficulty in dispersing pollutants, issues like smog and other air pollution problems may arise. As a result, environmental protection authorities enforce stricter emission regulations on businesses during winter, potentially raising emission standards or limiting total emission volumes. If asphalt plants continue production during winter, they must invest additional funds to upgrade environmental protection equipment and implement stricter emission reduction measures to comply with environmental regulations, thereby increasing operational costs.

Some regions also impose restrictions on the timing and location of winter construction activities to minimize environmental impacts. For example, in densely populated or environmentally sensitive areas, asphalt production and construction activities may be prohibited during winter. These regulatory restrictions also force asphalt plants to shut down during winter.

Cutting Pollution

Closing asphalt plants is one of the effective measures to reduce environmental pollution during winter. Pollutant emissions generated during asphalt production can have a greater impact on surrounding air quality under unfavorable meteorological conditions during winter. Closing factories can directly reduce pollutant emissions, alleviate pressure on the air environment, and improve surrounding air quality.

During winter, natural ecosystems are relatively fragile, with reduced activity and metabolism among plants and animals, and decreased adaptability to environmental changes. Noise and dust generated during asphalt production can also disrupt the surrounding ecological environment. Closing asphalt plants can reduce these disturbances, benefiting the stability of the surrounding ecosystems.

Additionally, the reduced volume of asphalt transportation during winter also decreases exhaust emissions and noise pollution caused by the operation of transportation vehicles. Therefore, from the perspective of reducing environmental impact, closing asphalt plants during winter aligns with environmental protection requirements.

Regional Differences and Exceptions

How Weather Shapes Work

Asphalt plants in different climate regions adopt distinct operational strategies during winter. In regions with mild winter climates, where temperatures rarely drop below 10 degrees Celsius and precipitation is minimal—such as certain southern coastal areas—asphalt production and construction are not significantly impacted, allowing asphalt plants to operate normally year-round. Road construction projects in these regions also do not experience large-scale delays during winter, and market demand for asphalt remains relatively stable.

In regions with cold winters, lower temperatures, and higher precipitation (especially snowfall), such as most northern areas, asphalt plants typically shut down during winter. This is because the climatic conditions in these regions do not meet the requirements for asphalt production and construction, and forcing operations would lead to issues related to quality, safety, and costs.

Some regions are located in climatic transition zones, where suitable weather conditions for construction occasionally occur during winter. Asphalt plants may temporarily resume operations based on weather forecasts, completing urgent construction tasks under permissible conditions before resuming closure. This operational strategy balances local climatic characteristics while partially addressing urgent market demands.

Exceptions for Special Projects

Although asphalt plants generally close during winter, exceptions may occur under certain circumstances. For example, when there is an urgent need for road repairs, such as severe damage to major traffic arteries affecting vehicle safety, immediate repairs are required. In such cases, asphalt plants may temporarily resume operations to produce a small amount of asphalt mixture for emergency repairs. Under these circumstances, special measures are typically taken to ensure construction quality, such as conducting work during relatively warmer time periods and implementing insulation measures for the asphalt mixture.

Additionally, some technologically advanced asphalt plants can address the challenges of low winter temperatures to some extent by adopting new asphalt materials and production processes. For example, modified asphalt is used to enhance flowability and adhesion at low temperatures, and advanced heating and insulation equipment is employed to minimize temperature loss during production and transportation. These plants may undertake some special construction projects during winter, but such cases are relatively rare and do not alter the overall trend of asphalt plants generally closing during winter.

Money and Plans

Closing Saves Money

From a cost-benefit perspective, closing asphalt plants during winter is typically more cost-effective than continuing operations. If operations continue during winter, on one hand, high operational costs must be borne, such as energy consumption, labor costs, and equipment maintenance costs; on the other hand, due to low market demand, product sales are difficult, and limited sales revenue may result in losses.

Closing the plant can save a significant amount of operational costs. Additionally, using the winter period for equipment maintenance and repairs can improve equipment efficiency during the peak production season the following year, reducing losses caused by equipment failures. Although closing the plant may result in the loss of some potential sales revenue, compared to the costs incurred by continuing operations, closing the plant can effectively control costs and improve the company’s overall economic efficiency.

From a long-term perspective, seasonal closures help companies balance production and costs, avoiding resource waste and economic losses caused by blind production during winter, making it a cost-effective choice.

Future Changes Possible

With ongoing technological advancements, the asphalt industry may achieve new breakthroughs in addressing winter production and construction, potentially altering the established practice of winter shutdowns for asphalt plants. For example, developing asphalt materials better suited for low-temperature environments to enhance low-temperature performance and reduce reliance on construction environment temperatures; or developing efficient insulation and heating technologies to minimize temperature loss in asphalt mixtures during production, transportation, and construction, thereby ensuring construction quality.

In terms of environmental protection, as environmental standards continue to rise, asphalt plants will continuously improve production processes to reduce pollutant emissions and develop environmentally friendly asphalt products. This may result in asphalt plants having a smaller environmental impact during winter operations, thereby securing more operational permits.

From a sustainable development perspective, the asphalt industry will place greater emphasis on the rational use of resources and environmental protection, exploring new models for winter production and construction. For example, optimizing production schedules to achieve seamless seasonal production transitions; utilizing winter periods for technological research and development and staff training to enhance the company’s core competitiveness. These trends and strategies may influence asphalt plant winter operations, and the practice of winter closures may gradually evolve in the future.

Conclusion

The closure of asphalt plants during winter is the result of multiple factors. Climate constraints pose significant technical challenges for asphalt production and construction during winter, making it difficult to ensure road quality; seasonal declines in market demand lead to difficulties in selling asphalt products, leaving factories without sufficient orders to sustain operations; the necessity of equipment maintenance and increased operational costs prompt factories to choose closure during winter from an operational management perspective; simultaneously, requirements for worker safety and environmental protection regulations further support the decision to close during winter.

Different regions adopt varying operational strategies based on their climate characteristics, but exceptions for special projects do not alter the overall trend of winter closures. This seasonal closure is a scientifically reasonable industry practice that benefits the asphalt industry by ensuring product quality, reducing operational costs, safeguarding worker safety, and protecting the environment.

Looking to the future, with technological advancements and the deepening of sustainable development concepts, the situation of asphalt plants closing during winter may change. However, in the short term, winter closures will remain the choice for most asphalt plants. The asphalt industry will continue to optimize operational strategies based on seasonal changes and market demand, striving to achieve a balance between economic, social, and environmental benefits.