In modern infrastructure development, asphalt mixing plants serve as core equipment for projects like road paving and airport runway construction. Their deployment efficiency directly impacts project timelines. Whether renovating urban thoroughfares, building new highways, or maintaining roads in remote areas, the timely arrival and stable installation of asphalt mixing plants are critical prerequisites for ensuring project quality and schedule adherence. The selection of transportation methods serves as the pivotal link between equipment manufacturers and construction sites, playing a decisive role in project implementation efficiency, cost control, and equipment safety.

Choosing the appropriate transportation method not only enhances installation efficiency by ensuring the complete and precise delivery of equipment components to the site—saving time for subsequent assembly and commissioning—but also effectively manages project timelines and costs. It prevents rework, delays, or additional expenses caused by improper transportation. Furthermore, a scientifically designed transportation plan maximizes protection for core equipment components, ensuring operational safety and performance stability during subsequent use.

This article will thoroughly dissect common transportation methods for asphalt mixing plants, analyze key factors influencing mode selection, compare the advantages, disadvantages, costs, and applicable scenarios of different methods, and provide targeted selection recommendations and safety precautions. It aims to offer infrastructure project practitioners comprehensive guidance on asphalt mixing plant transportation, asphalt plant logistics, and asphalt plant delivery methods.

Transportation solutions for asphalt mixing plants are not fixed; they require comprehensive consideration of multiple factors to formulate the optimal logistics strategy. The following are core elements influencing the selection of transportation methods:

These interconnected factors collectively determine the complexity of asphalt plant transport considerations, underscoring the importance of planning for asphalt plant relocation and asphalt equipment logistics.

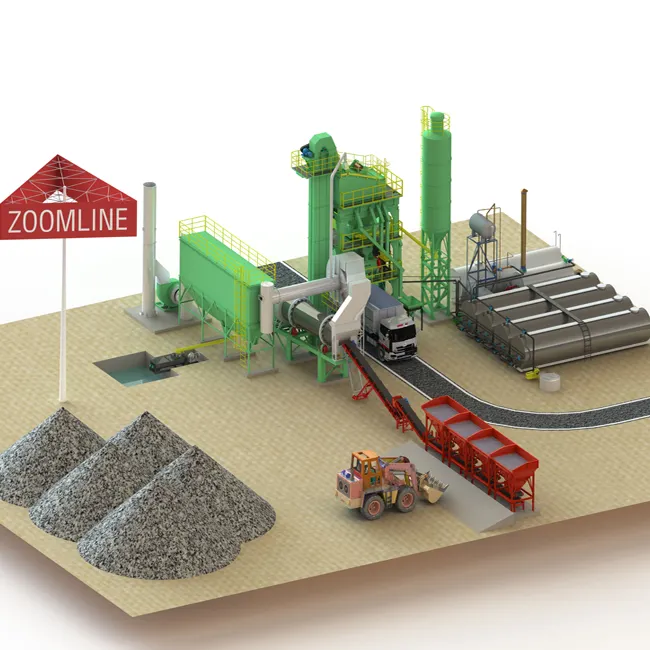

Fixed asphalt plants are heavy infrastructure equipment specifically engineered for sustained, long-term operation at a single construction site. Their core design philosophy centers on matching the high-intensity demands of large-scale, long-term infrastructure projects through stable structural layouts and robust production capacity. In terms of production capacity, standard models typically exceed 160 t/h. For mega-projects like super-highways, urban ring roads, and large airport runways, custom high-specification models of 300 t/h or more can be tailored to effortlessly handle continuous, large-scale asphalt mixture production. Performance-wise, the fixed asphalt mixing plant features a rigid, permanently installed structure that minimizes operational vibration. Paired with a high-precision electronic metering system and a twin-shaft forced-action mixing drum, it achieves precise blending of raw materials like aggregates, asphalt, and mineral powder. with mixing accuracy controlled within ±1%. This ensures the produced asphalt mixture meets stringent engineering standards for critical parameters like gradation and oil content. Their core functional components are complex and comprehensive, primarily including: – Large-capacity aggregate bins (typically equipped with 4-6 compartments for storing aggregates of different particle sizes) – Long-cylinder dryers (usually 8-12 meters in length, capable of efficiently drying aggregate moisture) a heavy-duty mixing main unit (featuring high-chromium wear-resistant blades for extended service life), an enclosed finished product silo (with insulation to prevent asphalt mixture clumping), and an efficient dust removal system (meeting stringent environmental emission standards). Given the heavy-duty design of each component—with individual parts weighing several tons to dozens of tons—their large size and low integration preclude whole-unit transportation. Professional modular disassembly is essential before shipping.

Given the large size and dispersed nature of stationary asphalt mixing plant components, the core transportation approach employs a comprehensive solution: “professional modular disassembly + large specialized vehicle transport + precise on-site reassembly.” The specific process comprises three critical stages: Stage One involves factory pre-disassembly. The manufacturer’s specialized technical team systematically dismantles the entire equipment system into multiple functionally independent standardized modules based on structural drawings and modular design plans. Common disassembly modules include aggregate silo modules, drying drum modules, mixing main unit modules, electrical control system modules, finished product silo modules, and dust removal system modules. Each module undergoes targeted numbering, interface protection (e.g., sealing caps for hydraulic and electrical connections), and reinforcement to prevent component damage or interface contamination during disassembly. Phase Two involves transportation implementation. The disassembled functional modules require specialized large-scale transport vehicles of varying specifications. For oversized, over-width, and heavy modules like the drying cylinder and mixing main unit, low-bed semi-trailers or recessed flatbed trailers are employed. These vehicles feature exceptionally low loading platforms and robust load-bearing capacity, effectively lowering the center of gravity during transport and enhancing driving stability. For precision modules like electrical control cabinets, enclosed box trucks are used to shield them from external elements (rain, dust, vibration). During transport, each module is secured to the vehicle deck via multiple points using high-strength steel cables and tensioning straps. Anti-slip mats and impact-absorbing buffers are also employed to prevent module shifting or collisions. Phase Three: On-site Reassembly and Commissioning Upon arrival at the construction site, all equipment modules require precise positioning and assembly using large-capacity cranes (50 tons or higher) or crawler cranes. Following numbered markings and installation drawings, the main structure is first assembled and secured. Subsequently, hydraulic systems, electrical circuits, and material conveying pipelines are connected. Finally, a series of procedures—including no-load trial runs and load testing—ensures all equipment performance meets standards before formal production commences.

Mobile asphalt mixing plants are designed around the core principles of “high efficiency and mobility, rapid deployment.” They feature a highly integrated, unified architecture that differs from the decentralized component layout of fixed equipment. Key functional components—including the twin-shaft forced-action mixing main unit, layered aggregate bins (typically 2-4 compartments, suited for small-scale project aggregate storage needs), high-efficiency energy-saving drying drums, compact finished product silos, asphalt storage tanks, and complete electrical control systems—are all compactly designed and integrated onto a mobile heavy-duty towing chassis or trailer frame. This integrated design not only significantly reduces the overall footprint but also ensures stable, coordinated operation of all components through standardized connection interfaces and modular structural layouts. To further enhance mobility, the unit incorporates auxiliary devices like dedicated tow pins and hydraulic outriggers. The hydraulic outriggers deploy rapidly upon arrival at the transport destination, enabling precise positioning and stable anchoring without requiring additional foundation pouring. In terms of production capacity, mobile asphalt mixing plants are constrained by the spatial limitations of their integrated design, resulting in lower output compared to stationary units. Standard capacity ranges typically fall between 80-160 t/h, while certain compact, lightweight models can operate as low as 20 t/h—ideally matching the production demands of small to medium-sized projects. Their applicability is highly targeted, primarily covering three project types: First, short-term road maintenance projects such as pothole repairs and pavement resurfacing on urban secondary roads and rural highways. These projects feature brief construction cycles (typically 1-3 months) and dispersed locations, where mobile equipment can flexibly shuttle between multiple work sites. Second, small-scale road construction projects like internal community roads, industrial park access roads, and scenic area trails. These projects involve modest workloads and lower capacity demands, where mobile equipment’s rapid deployment capability significantly shortens project preparation cycles. Third, emergency repair projects, such as road damage caused by natural disasters like heavy rains or earthquakes, or urgent handling of sudden pavement defects on highways. Mobile equipment can arrive at the site and commence production within a short timeframe, providing critical support for rapid road restoration.

Transportation convenience is a core advantage of mobile asphalt mixing plants, manifested in end-to-end efficiency through “no disassembly required, rapid relocation, and simple deployment.” Unlike the complex modular disassembly process of stationary equipment, mobile units feature integrated designs that eliminate the need to dismantle major components before transport. Only targeted protection is required for a few vulnerable or precision parts. Specific protective measures include: – Enclosing electrical control cabinets with waterproof and dustproof covers to prevent rain and dust ingress during transit. – Installing cushioning foam and protective housings on precision instruments like sensors and pressure gauges to avoid damage from vibration and shock. – Sealing exposed hydraulic ports and pipe fittings with protective caps to prevent contamination that could affect subsequent operation. During the transportation phase, no large specialized transport vehicles are required. Instead, a heavy-duty tractor unit (such as a semi-trailer tractor) compatible with the equipment’s tow pin is selected. After securely connecting the equipment frame via a dedicated towing device, it can be directly towed to the construction site. Notably, due to standardized dimensional design, most models comply with standard highway transport requirements—except for certain oversized mobile units—eliminating the need for oversize transport permits and further streamlining logistics. Upon arrival at the site, deployment remains simple and efficient: First, rapidly deploy the equipment’s built-in hydraulic support legs to achieve level positioning and secure stabilization without requiring additional concrete foundations. Next, connect the power supply, inspect all component connections, and conduct simple no-load test runs on core components like the mixing main unit and drying drum to check for any loosening or abnormalities caused during transportation. The entire positioning, securing, and commissioning process can typically be completed within 2-4 hours, with the fastest time being 1.5 hours before formal production begins, significantly reducing the project’s preparatory time.

Semi-mobile/portable asphalt mixing plants represent a hybrid equipment type precisely positioned between the “stable production capacity of fixed equipment” and the “flexible mobility of mobile equipment.” Their core design philosophy involves scientifically modular disassembly and integrated design to overcome the operational limitations of both categories, achieving a balanced advantage of “medium production capacity + convenient relocation.” Structurally, it abandons the rigid monolithic connections of fixed plants and the fully integrated layout of mobile plants. Instead, it adopts a “core functional modularization with standardized connection interfaces” approach, disassembling the plant into 3-6 large functional modules (e.g., aggregate silo and dryer integrated module, mixing main unit and finished product silo module, electrical control system module). Each module retains the heavy-duty design characteristics of fixed equipment’s core components while reducing relocation complexity through lightweight optimization and standardized interfaces. This modular structure not only facilitates transportation but also ensures operational stability post-installation, eliminating vibration transmission issues inherent in fully integrated mobile equipment. In terms of production capacity, its standard output range falls between 100-200 t/h, strategically positioned between stationary plants (160 t/h and above) and mobile plants (80-160 t/h). This capacity meets the continuous production demands of medium-scale projects without causing equipment underutilization due to excess capacity. Its application scenarios are highly targeted, primarily suited for two project types: First, mid-term projects spanning six months to two years, such as urban secondary road renovations, county highway upgrades, and industrial park main road construction. These projects present a balanced timeline where fixed equipment proves economically inefficient due to high initial costs, while mobile equipment may struggle with insufficient capacity. Semi-mobile/portable equipment offers the ideal match with its moderate output and reasonable installation cycle. Second, infrequently relocated projects, such as multi-section rural road network interconnections or small-scale cross-regional infrastructure support projects. These projects require sequential operations at 2-3 fixed locations without frequent site transfers. Semi-mobile/portable equipment can be relocated with simple disassembly, significantly reducing repeated transportation and installation costs compared to fixed equipment while offering more stable production output than mobile equipment. Additionally, in certain medium-sized projects in remote areas, where on-site lifting capabilities are limited, the weight and dimensions of semi-mobile/portable equipment modules are better suited to local transportation and lifting capacities, making them the preferred choice.

Semi-mobile/portable asphalt mixing plants primarily utilize containerized or skid-mounted modular transportation solutions: Prior to shipment, the equipment is precisely disassembled into 3-6 large functional modules. Containerized modules are strictly designed to meet 20-foot or 40-foot shipping container dimensions, while skid-mounted modules feature standardized skid bases. All modules are transported via flatbed trucks, secured with multi-point fastening and protective measures during transit. Upon arrival at the construction site, positioning and assembly of the modules require only simple lifting equipment such as 16-25 ton conventional truck cranes, eliminating the need for 50-ton or larger cranes. This streamlined installation process significantly reduces demands on site conditions.

For overseas infrastructure projects or deploying large asphalt mixing plants in remote areas, containerized transport emerges as the industry’s most mainstream and reliable solution due to its stability and adaptability. Specifically, this method involves disassembling the asphalt mixing plant into standardized modules, core precision components, and supporting accessories based on functionality. Components are then loaded into either 20-foot/40-foot standard containers or customized special containers according to their dimensions, enabling standardized packaging and transportation of all equipment components.

The core advantages of container shipping lie in its end-to-end efficiency and security guarantees, summarized in four key benefits: First, strong multimodal compatibility. Standard containers seamlessly integrate with maritime, rail, and road transport, effortlessly overcoming cross-border shipping barriers for overseas projects and transportation constraints in remote areas to ensure precise delivery to project sites. Second, streamlined and efficient customs clearance. Standard containers fully comply with international shipping regulations, simplifying customs inspection procedures and cycles while reducing clearance delays caused by non-compliant packaging, significantly boosting cross-border transport efficiency. Third, comprehensive protection for core components. Containers offer superior sealing, moisture resistance, impact resistance, and vibration damping. They effectively shield against adverse external factors like marine salt spray, humid environments, and long-distance transport vibrations, providing comprehensive protection for core vulnerable components such as electrical control systems and precision bearings in mixing hosts, preventing damage during transit. Fourth, streamlined storage and assembly management. Each container is clearly labeled with the names, specifications, quantities, and corresponding installation stations of the components it carries. This facilitates inventory checks during transportation and enables the on-site installation team to quickly complete component verification and classification, laying an efficient foundation for subsequent modular assembly.

Asphalt mixing plants are high-value heavy equipment with precision core components and complex structures. Safety management throughout the entire transportation process directly determines equipment delivery quality and project cost control. Any transportation safety issues can easily lead to significant losses such as equipment damage and project delays. The following outlines key safety points and regulatory requirements for each transportation phase:

Pre-transportation Comprehensive Inspection and Protection:

Form a specialized inspection team to conduct a full-dimensional check of all equipment components prior to transport. Focus on confirming the integrity and secure fastening of critical parts such as bolts, hydraulic connectors, and electrical fittings to prevent loose or missing components during transit. For precision components like sensors and measuring instruments, implement dual protection using custom cushioning packaging plus protective casings. Apply rust inhibitors to corrosion-prone parts. Simultaneously, rigorously verify the transport vehicle’s load capacity, brake system responsiveness, tire wear level, and loading platform flatness to ensure full compliance with transport requirements. Eliminate the use of vehicles with existing defects.

Secure Module Fixation and Load Balancing: After loading equipment modules, employ a combination of high-strength steel cables, professional tensioners, and anti-slip blocks for fixation. Follow the principle of “multi-point symmetry and uniform force distribution” to ensure no relative sway or displacement gaps between modules and the vehicle’s loading platform. During loading, precisely calculate each module’s weight, scientifically plan loading positions, and strictly control vehicle center-of-gravity deviation within safe limits. Oversized or overweight modules require additional anti-rollover supports to fundamentally eliminate the risk of overturning during transport.

Specialized Protection for Electrical & Control Systems: Electrical components including control cabinets, cable trays, and sensors must be fully enclosed with sealed waterproof/dustproof covers. Interfaces shall be sealed with specialized caps to prevent rain and dust ingress during transit. Buffer foam pads must surround electrical components to mitigate impact damage from vehicle vibrations. Outdoor-transported electrical modules require additional sun/rain-resistant tarps to withstand extreme weather conditions.

Strict Compliance with Local Transportation Regulations: Thoroughly review traffic management regulations along the transport route in advance. For oversized or overweight modules, submit a transport application to relevant traffic authorities 7-10 business days prior, providing complete documentation including vehicle certification, transport plan, and safety measures. Upon approval, arrange dedicated personnel and vehicles for full-process escort. Strictly adhere to transportation time windows, avoiding urban morning/evening rush hours and nighttime restrictions. When traversing bridges, tunnels, or other special sections, reduce speed and employ dedicated personnel for traffic direction to ensure compliant and orderly transport.

Multi-Party Collaborative Assurance: Establish a tripartite coordination mechanism among manufacturers, transport companies, and construction/installation teams, clearly defining responsibilities—manufacturers provide equipment disassembly and protective technical guidance; transport companies implement safety controls; construction teams handle on-site reception and crane coordination. Pre-plan optimal routes with contingency alternatives, establish real-time communication channels, and report transportation status every two hours during transit. In case of traffic congestion or vehicle malfunctions, the three parties must rapidly coordinate solutions to ensure equipment arrives on-site smoothly and facilitates seamless installation.

Cost is a core consideration when selecting transportation methods for asphalt mixing plants. Significant variations exist in the cost structures of different transportation solutions, with profound implications for the project’s total lifecycle cost. Therefore, a systematic comparison analysis from a lifecycle perspective is essential to accurately control cost risks and achieve optimal cost-effectiveness:

Initial Transportation Costs: Among all transport methods, fixed plants incur the highest initial transportation costs. They require disassembly into multiple large functional modules, necessitating the coordination of multiple specialized vehicles like low-bed semi-trailers. Mobile plants have the lowest initial costs, as their integrated design allows for complete towing by a single heavy-duty tractor unit, eliminating the need for additional specialized vehicles. Semi-mobile/portable plants fall between these two extremes, with 3-6 modular components transported via standard flatbed trucks. For overseas or remote projects, container shipping incurs higher initial costs due to international transit, container leasing, and specialized handling, plus additional cross-border transportation fees.

Installation and Commissioning Costs: These costs are directly tied to the complexity of the transportation method. Fixed plants involve the most intricate installation procedures, requiring rental of 50-ton or larger cranes alongside specialized installation teams for module assembly, piping connections, and system commissioning, resulting in the highest costs. Mobile plants offer the lowest installation expenses, requiring only hydraulic outrigger positioning, power connection, and basic no-load testing upon site arrival—completed within 2-4 hours without additional heavy equipment or specialized crews. Semi-mobile/portable plants fall in the middle range for installation and commissioning costs. Module assembly can be completed using standard truck cranes, with commissioning taking 2-3 days. For export projects, container transportation incurs additional costs for on-site unloading, customs clearance agents, and cross-border technical coordination, further increasing the overall investment during the installation and commissioning phase.

Long-term operational cost implications: From a full lifecycle perspective, initial cost levels are not the decisive factor for long-term operational economics. While fixed plants have higher initial transportation and installation costs, their stable structural design and low failure rates result in extremely low maintenance expenses during long-term operation, yielding the lowest unit production cost—particularly suited for projects exceeding two years. Mobile plants, due to their lightweight design and integrated layout, experience faster wear on core components, requiring higher maintenance and replacement frequencies over extended operation, resulting in relatively higher maintenance costs. Semi-mobile/portable plants fall between these two extremes in long-term operational costs, ensuring stable operation for medium-term projects while maintaining reasonable maintenance expenditures, thus balancing short-term and long-term costs.

Hidden Costs: Often overlooked yet significantly impacting total project costs, these primarily include transportation permit fees, oversize escort fees, schedule delay penalties, and equipment damage repair costs. Fixed plants’ hidden costs mainly stem from time and expense invested in obtaining oversize transport permits, plus potential schedule delays due to extended installation periods. Mobile plants incur the lowest hidden costs due to simplified transport processes and no need for oversize permits. Hidden costs for export projects are more complex. Beyond conventional hidden costs, they include customs inspection demurrage fees, exchange rate fluctuation losses during cross-border transportation, and international logistics delay losses. These must be anticipated and budgeted for during the planning phase.

Transportation method selection must align closely with project realities. Only through deep alignment between the transportation plan and project requirements can both efficiency gains and cost optimization be achieved. The following targeted recommendations, distilled from industry practice, serve as a reference for project practitioners:

Precise Matching Based on Project Duration and Scale: For large-scale infrastructure projects with durations exceeding two years (e.g., expressway mainlines, major airport runways, urban ring road projects), fixed asphalt mixing plants are recommended as the primary choice. Although their transportation and installation cycles are longer, their high production capacity exceeding 300 t/h meets continuous production demands, and their advantages of low failure rates and low unit costs during long-term operation are more pronounced. For small-scale projects with a duration of less than one year (e.g., rural road upgrades, urban secondary road maintenance, community internal road construction), mobile mixing plants are the optimal choice. Their “transport and deploy immediately” feature enables rapid response to construction needs, significantly reducing overall logistics and time costs. For medium-scale projects with durations ranging from six months to two years (e.g., county-level arterial road upgrades, industrial park main road construction), semi-mobile/portable mixing plants strike a balance between flexibility and production capacity, precisely matching phased project requirements.

Determine the solution based on relocation frequency: For projects requiring frequent relocation (e.g., continuous highway maintenance across multiple sections, small-scale cross-regional infrastructure projects), prioritize mobile batching plants. Their integrated towing design eliminates disassembly, drastically shortening relocation time and boosting construction efficiency. For projects requiring only 1-2 infrequent relocations (e.g., multi-village networked highway construction, zoned municipal renovation projects), semi-mobile/portable plants offer superior cost-effectiveness. Their modular disassembly design reduces repeated transportation and installation costs. For long-term fixed-location projects requiring no relocation (e.g., dedicated plants for large industrial parks, urban road maintenance bases), stationary plants provide stable output and durability better suited to sustained operational needs.

Selecting the Right Type Based on Budget Constraints: Projects with ample budgets seeking long-term investment returns should opt for fixed asphalt mixing plants. The higher upfront transportation and installation costs can be amortized through stable long-term operation, achieving optimal lifecycle costs. Projects with limited budgets prioritizing short-term return on investment should choose mobile mixing plants. Their lower initial transportation and installation costs effectively alleviate financial pressure. For projects with moderate budgets requiring a balance between short-term investment and long-term benefits, semi-mobile/portable plants are ideal. They ensure production capacity while controlling logistics and operational costs within reasonable limits.

Consider site accessibility when selecting transportation solutions: For projects located in urban cores, areas with narrow roads, or sites inaccessible to large lifting equipment (e.g., old city road renovations, residential area road construction), prioritize mobile plants. Their compact structure and simple deployment adapt to complex site conditions. For sites with wide roads and access for large lifting equipment (e.g., suburban highway sections, infrastructure projects in newly developed areas), fixed or semi-mobile plants can be selected based on project duration and scale; For overseas or remote projects (e.g., border highway construction, international infrastructure projects), containerized transport is the preferred method. Multimodal logistics can overcome transportation barriers, ensuring safe and efficient equipment delivery.

Consult specialized manufacturers for customized solutions: Asphalt mixing plants from different manufacturers vary in modular design, core component performance, and suitability for specific scenarios. It is advisable to proactively engage experienced equipment suppliers during the project’s early stages. Manufacturers can provide customized logistics and transportation solutions based on their equipment characteristics and the project’s actual conditions (such as schedule, production capacity requirements, site environment, and transportation routes). This helps avoid risks such as equipment damage, schedule delays, and cost overruns caused by improper selection, ensuring smooth project progress.

Common transportation methods for asphalt mixing plants include:

– Modular disassembly transport for fixed equipment

– Full-unit towing transport for mobile equipment

– Modular container transport for semi-mobile/portable equipment

– Container intermodal transport for export projects

Each method has distinct advantages and disadvantages, suited to different project timelines, scales, budgets, and site conditions.

The optimal transport method is neither the most convenient nor the cheapest; the core principle is achieving precise alignment between the transport approach and project requirements. An appropriate transport method effectively enhances installation efficiency, controls project costs, ensures equipment safety, and lays the foundation for smooth project execution.

Finally, infrastructure project practitioners are advised to thoroughly research actual project requirements and proactively consult experienced asphalt plant suppliers before selecting a transport method. Professional suppliers can provide customized asphalt plant logistics solutions tailored to equipment characteristics and project scenarios, facilitating efficient project implementation.