In modern road construction, highway maintenance, and rural infrastructure projects, mobile asphalt mixing plants have become core equipment for improving engineering efficiency due to their flexible relocation and on-site production capabilities. Compared to traditional fixed equipment, their modular design can quickly respond to different construction scenarios, significantly reducing asphalt transportation costs and time losses. This article will systematically analyze the entire setup process of a mobile asphalt mixing plant, from equipment principles, preliminary preparations, installation steps to post-installation commissioning, providing engineering teams with a technical reference that combines professionalism and practicality.

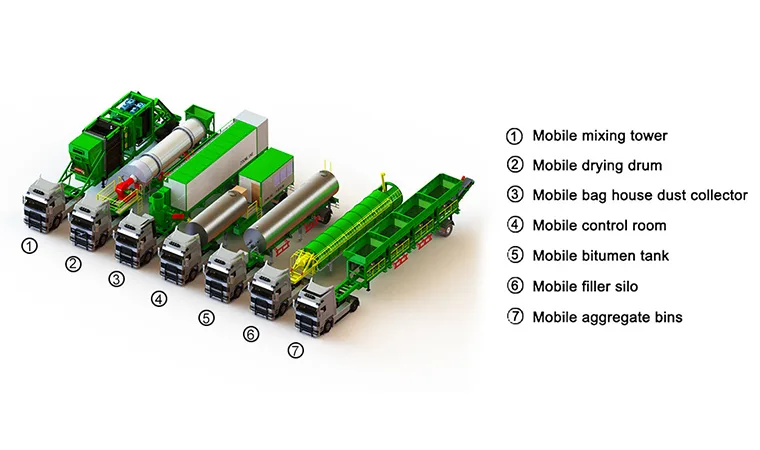

A mobile asphalt mixing plant is a compact, movable version of traditional fixed equipment, integrating core components such as cold aggregate feeders, drying drums, burners, dust collectors, hot aggregate elevators, vibrating screens, hot material silos, mixers, asphalt tanks, control cabinets, and storage silos into a single chassis or wheeled/skid-mounted modular unit. Its typical application scenarios include:

On-site asphalt production for new highway construction and maintenance projects;

Projects requiring frequent relocation, such as airport runway renovations and rural road construction;

Material supply needs in remote areas or temporary construction sites.

The efficient operation of a mobile asphalt mixing plant relies on the coordinated functioning of its components, with core components including:

Cold aggregate feed hopper: responsible for conveying aggregates such as sand and gravel according to the mix ratio;

Drying drum: dries wet aggregates at high temperatures to prepare them for mixing;

Baghouse dust collector: captures dust generated during production to ensure environmentally compliant emissions;

Bucket elevator: vertically conveys dried hot aggregates to the tower top unit;

Tower top unit: integrates a vibrating screen, hot aggregate silo, and mixing device to complete aggregate screening and asphalt mixing;

Asphalt storage tank: equipped with a thermal oil heating system to store and convey liquid asphalt;

Fuel tank: supplies fuel oil or natural gas to the drying drum burner;

Mineral filler unit: precisely adds mineral powder and other additives to optimize asphalt performance;

Control cabin and panel: Centralized control of the entire equipment operation, achieving automated production.

The equipment can be transported to any construction site via a trailer, enabling asphalt production directly at the construction site, avoiding the drawbacks of traditional fixed equipment requiring long-distance transportation of finished materials, particularly suitable for mountainous or remote areas with poor transportation infrastructure.

Eliminates fuel consumption and vehicle wear from asphalt transportation;

Modular installation allows for quick commissioning, reducing downtime and accelerating project profitability.

Utilizes advanced mixing technology to ensure uniform blending of aggregates and asphalt, with finished materials meeting the high strength and durability requirements of road construction, effectively extending pavement lifespan.

On-site production reduces carbon emissions from transportation;

Standard dust collection systems and exhaust gas treatment systems meet modern construction environmental compliance requirements.

Equipment design prioritizes ergonomics, enabling trained operators to quickly master control processes, reducing labor costs and operational barriers.

Site selection principles: Ensure the mixing plant building is located for easy access by transport vehicles, with material yards and asphalt tanks arranged according to material flow logic;

Control room layout: Must have an unobstructed view, not obstructing construction vehicle traffic, while facilitating monitoring of the entire plant’s operations;

Foundation construction: Pour concrete foundations according to the manufacturer’s provided foundation drawings, ensuring load-bearing capacity and levelness meet standards.

Component inventory: Compare against the equipment configuration list to verify the completeness of the cold feed system, drying drum, mixing unit, etc., and verify the quantity of accessories (bolts, cables, etc.);

Personnel qualifications: The installation team must undergo technical briefings and professional training to familiarize themselves with equipment structure and safety procedures;

Compliance procedures: Obtain construction permits and registrations from local environmental protection and safety authorities in advance to ensure project legality and compliance.

Self-Elevating Storage Silos: Use a hydraulic pump unit to lift the silo body and scraper conveyor to the designated position, then secure it in place according to the drawings;

Non-Self-Elevating Storage Silos: Use a crane for lifting. Before lifting, confirm that the equipment weight matches the crane’s tonnage capacity, and strictly adhere to lifting equipment inspection and safety rope usage regulations.

Install support legs when the bin body is lying horizontally; for large bins, secure the crossbeams first before tightening the bolts;

Pre-install accessories such as handrails and batch hoppers before lifting; after positioning, weld the support legs to the foundation steel plates to ensure stable load-bearing.

Use two lifting points at both ends for lifting. Note that the conveyor head is heavier, so maintain balance;

After the tail end is placed on the foundation steel plate, weld or bolt-fix the support brackets, and install dust covers and maintenance platforms.

Mark the drum position according to the foundation diagram, and use hydraulic legs or manual leveling devices to ensure horizontal alignment;

Connect the drum discharge port to the scraper conveyor feed port, install a sealed inclined chute to prevent aggregate leakage.

Position the weighing conveyor using the drying drum discharge port as a reference, ensuring material falls into the chute center;

Deploy the collection conveyor below the aggregate silo, adjust the angle to align with the weighing conveyor, and install support chains to prevent sagging.

Baghouse Dust Collector: Connect the ductwork to the drum exhaust outlet, use sealing material to fill the joints, and install the fan and ash discharge screw;

Asphalt Tank and Fuel Tank: The asphalt tank must be installed near the injection piping, and the fuel tank must maintain a safety distance of over 50 feet from the burner, equipped with filters and explosion-proof devices.

Ensure equipment emissions (dust, noise) comply with local environmental standards; obtain an emissions permit in advance;

Fuel storage areas must have leak-proof pits; asphalt leakage emergency pits must be constructed according to specifications.

Electrical system wiring must be performed by licensed electricians, with all equipment grounding resistance ≤4Ω;

High-altitude work must use lifting platforms; standing or walking under suspended loads is strictly prohibited.

Mark the locations of wear-prone components (e.g., belts, burner nozzles) during installation and establish a regular replacement schedule;

Configure lubricants for the lubrication system according to the manual requirements, and check the oil circuit for smooth flow before commissioning.

When relocating a project, the following principles must be followed when dismantling equipment:

Pre-dismantling preparation: Read the manufacturer’s manual in detail and mark all pipeline interfaces and electrical connection points;

Professional team operation: Hire an experienced dismantling team to avoid component damage due to improper operation;

Transportation protection: Wrap precision components (such as sensors and control cabinets) with shock-absorbing materials and secure them to the transport vehicle to prevent vibration.

Verify that the equipment installation dimensions match the drawings, and use a level to remeasure the inclination of critical components (such as drums and screens);

Conduct power-on tests to verify motor rotation directions and check if variable frequency drive parameters are aligned with production requirements.

Perform a full-process no-load trial run: cold feeding → drying → screening → mixing → unloading, to confirm no blockages in any stage;

Conduct asphalt injection pressure tests to ensure no pipeline leaks and that the weighing scale accuracy error is ≤±0.5%.

Conduct small-batch trial mixing according to the design mix ratio, and test the asphalt content, aggregate gradation, and Marshall stability;

Adjust parameters such as drying temperature and mixing time based on the trial mixing results until the finished material meets construction specifications.

Prioritize emptying residual material from the asphalt weighing tank, then initiate the “pot cleaning” program to remove residual asphalt from the mixing tank;

Shut down equipment in sequence: asphalt circulation pump → coal powder screw conveyor → screen → elevator, with a 10–15-second interval between each device to prevent material buildup.

After shutdown, close all fuel valves and inspect the circuit breaker status of the distribution panel;

Regularly clean the filter bags of the baghouse dust collector to prevent dust accumulation and fire hazards.

The efficient setup of a mobile asphalt mixing plant must balance equipment principles, construction standards, and project characteristics. Every stage, from initial site planning to final commissioning, must prioritize professionalism and safety. Through a systematic installation process and meticulous attention to detail, not only can equipment be put into operation promptly, but it also lays the foundation for efficient production and low-maintenance operations in the future, ultimately achieving dual improvements in engineering quality and economic benefits. For customized installation solutions, it is recommended to collaborate with professional technical teams based on equipment models and project conditions.