How is hot-mix asphalt manufactured?

Hot-mix asphalt is indispensable

In the global modern road network, hot-mix asphalt is an irreplaceable “lifeline material.” From highways carrying massive traffic flows and municipal streets ensuring urban commuting to airport runways withstanding extreme loads, hot-mix asphalt, with its excellent adhesion, stability, and durability, has become the preferred choice for road paving. The core hub supporting the high-quality, large-scale, and controllable production of this crucial material—the asphalt mixing plant—is the “power heart” of modern road construction. A modern asphalt plant can stably produce 2,000-6,000 tons of high-quality hot-mix asphalt daily. Its technological precision and operational efficiency directly determine the service life of roads, driving safety, and maintenance costs, making it the industrial cornerstone ensuring smooth and reliable transportation networks. Without advanced asphalt mixing plants, the large-scale supply of high-quality hot-mix asphalt is impossible, and road construction will stagnate.

Basic Components of Hot-Mix Asphalt

The superior performance of hot-mix asphalt stems from its scientifically precise component blending, which is perfectly integrated under the control of the asphalt mixing plant. Aggregates are the absolute main component, accounting for approximately 95% of the total weight of the mixture, primarily including crushed stone, manufactured sand, and natural sand. The asphalt mixing plant rigorously grades and screens these aggregates, ensuring that aggregates of different particle sizes work together—coarse aggregates form a stable framework, while fine aggregates fill the gaps, providing sufficient structural strength to the mixture.

Approximately 5% of the asphalt binder is the “bonding soul” of hot-mix asphalt, commonly including petroleum asphalt, modified asphalt, and polymer-modified asphalt. When heated, it exhibits good fluidity, evenly coating each aggregate particle; upon cooling, it forms a strong binding force, coheding loose aggregates into a cohesive whole. Furthermore, mineral powder and additives act as performance “optimizers.” Mineral powder enhances the adhesion between asphalt and aggregates, while additives specifically improve the mixture’s high-temperature rutting resistance, low-temperature crack resistance, and water damage resistance. Notably, under modern environmental protection principles, recycled asphalt (RAP) has become an important component of hot-mix asphalt. With the technical support of advanced asphalt mixing plants, its addition ratio can reach 30%-50%, saving resources and reducing costs.

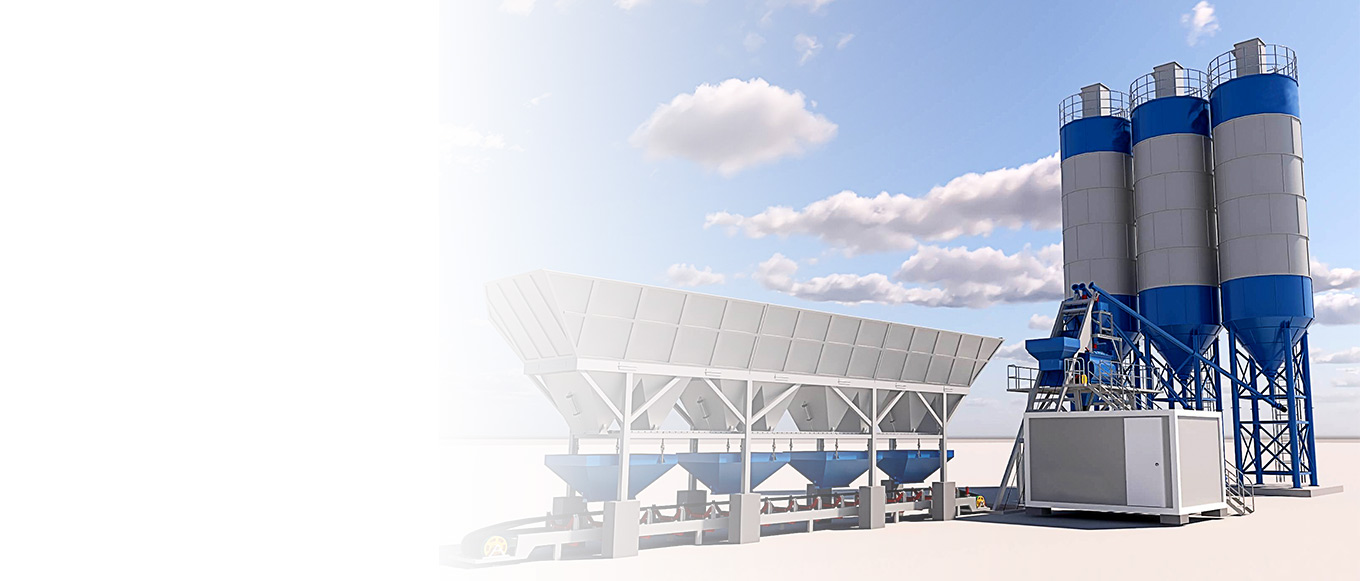

Two Main Types of Asphalt Mixing Plants

As the core carrier of hot-mix asphalt production, asphalt mixing plants can be divided into two main types according to their production mode. They are adapted to different engineering needs and jointly support the diverse scenarios of road construction.

It is currently the most widely used type, and its core features are “batch production and precise control”. Asphalt mixing plants measure and mix each batch of raw materials separately, and can flexibly adjust the formula to ensure that the quality of each batch of hot-mix asphalt is uniform and stable. Therefore, it is particularly suitable for key projects with extremely high quality requirements, such as highways and airport runways.

The advantage of this type of mixing plant lies in its “highly efficient continuous operation.” The drying and heating of aggregates and the mixing of asphalt are completed continuously within the same rotating drum, resulting in a production efficiency far exceeding that of intermittent plants. This makes it suitable for projects with large workloads and high production speed requirements, such as urban road reconstruction and expansion, and rural road construction. Although the two types of mixing plants have different process paths, they both use standardized production systems to transform dispersed raw materials into hot-mix asphalt that meets engineering standards, making them indispensable core facilities for hot-mix asphalt manufacturing.

Complete Production Process of Intermittent Asphalt Mixing Plant

The production process of intermittent asphalt mixing plants is a model of precision manufacturing, with each step proceeding in an orderly manner under strict control to ensure the quality of hot-mix asphalt is controllable.

- Cold aggregate supply and initial batchingDifferent sizes of cold aggregates are stored in multiple cold aggregate bins in the asphalt mixing plant. Each bin is equipped with an adjustable gate and a feeder. The outflow of each type of aggregate is precisely controlled through a preset program to achieve preliminary proportioning and lay the foundation for subsequent production.

- Cold aggregate conveying and drying/heatingAfter initial mixing, the cold aggregate is conveyed into a rotary drying drum. The burners in the asphalt mixing plant generate high-temperature hot air, heating the aggregate to 150-170℃. This process not only thoroughly removes moisture from the aggregate (preventing voids in the mixture), but also creates the necessary temperature conditions for subsequent fusion with asphalt.

- Hot aggregate screening and hot silo storageThe heated aggregate is fed into a vibrating screen, where the asphalt mixing plant re-grades it according to particle size using multiple layers of screens to ensure accurate gradation. The screened hot aggregate is then stored in corresponding hot aggregate bins for insulation, awaiting the next step of metering.

- Secondary precise metering of hot aggregatesAccording to the preset formula, the high-precision weighing system of the asphalt mixing plant will perform a second precise measurement of the aggregate in each hot aggregate bin, and the error can be controlled within ±0.5%. This is a key link to ensure the stability of hot-mix asphalt gradation.

- Asphalt heating and precise meteringThe asphalt binder is heated to 150-170℃ in a special heating tank at the asphalt mixing plant to give it good fluidity. It is then delivered proportionally by a high-precision metering device with a metering error of only ±0.1%, ensuring accurate asphalt-aggregate ratio.

- Measurement of mineral powder and additivesMineral powder and various functional additives are also precisely added through a dedicated metering system to further optimize the performance of the mixture.

- Forced intermittent mixingAll metered raw materials are fed into a twin-shaft mixing drum and forcibly mixed under the control of the asphalt mixing plant. The mixing time of 35-60 seconds ensures that the asphalt can evenly coat each aggregate to form a homogeneous mixture.

- Finished material storage and unloadingThe hot-mixed asphalt is temporarily stored in an insulated silo or directly loaded into transport vehicles and sent to the construction site to ensure that the mixture is laid at the specified temperature.

- Waste gas and dust treatmentThe dust and exhaust gas generated during the production process will be treated by the bag filter + secondary dust removal system of the asphalt mixing plant to ensure environmentally friendly emissions. The dust emission concentration can be controlled below 10mg/Nm³.

Production Process of Continuous Asphalt Mixing Plant

The production process of a continuous asphalt mixing plant is based on “high-efficiency integration”, which integrates multiple links into one, greatly improving production efficiency.

- Simultaneous proportional supply of cold-pressed materials from multiple warehousesSimilar to the intermittent type, cold aggregates of different particle sizes flow out synchronously from multiple cold silos in a preset ratio and are conveyed to the drying drum by a conveyor belt.

- Integrated cold material drying and heatingAfter the cold aggregate enters the rotating drying drum, it is simultaneously dried and heated by the high-temperature hot air generated by the burner as it travels along the drum wall, removing moisture and reaching the target temperature.

- Asphalt and mineral powder are added simultaneously.In the middle and rear section of the drying drum (mixing zone), the asphalt mixing plant will precisely spray heated asphalt and mineral powder through special nozzles. Depending on the design, parallel flow or counterflow can be used to ensure full contact of the materials.

- Continuous mixing and homogenizationUnder the continuous rotation of the drying drum, aggregates, asphalt, and mineral powder are continuously mixed to form homogeneous hot-mix asphalt.

- Finished product unloading and storageThe hot-mixed asphalt is directly unloaded into transport vehicles or temporarily stored in small insulated warehouses to ensure continuous supply.

- Flexible and controllable addition of recycled materialsFor recycled asphalt (RAP), continuous asphalt mixing plants can add it through either a central (directly added to the drying drum) or an external (added after separate treatment) method to achieve resource recycling.

Temperature Control in Hot Mix Asphalt Production Process

Temperature is the “lifeline” of hot-mix asphalt production. Asphalt mixing plants use fully automatic temperature control systems to precisely control the temperature at each stage, which directly affects the performance of the mixture.

- Core Temperature StandardThe aggregate heating temperature needs to be stabilized at 150-180℃ to ensure thorough removal of moisture and facilitate asphalt coating; the asphalt heating temperature should be controlled at 145-170℃ to ensure fluidity and prevent aging; the temperature of ordinary asphalt mixtures leaving the factory is 150-185℃, while the temperature of modified asphalt mixtures needs to be increased to 165-195℃ due to the characteristics of the modifiers.

- Hazards of Abnormal TemperaturesExcessive temperature can cause asphalt to age prematurely and lose adhesion, making the paved road prone to cracking and loosening. Conversely, excessively low temperature can result in uneven asphalt coating, difficulty in compacting the mixture, and a pavement with excessive porosity, making it susceptible to water damage and load failure. A real-time temperature monitoring and feedback system at the asphalt mixing plant can promptly adjust burner power and material conveying speed to prevent abnormal temperatures.

Core Technology Upgrades of Modern Asphalt Mixing Plants

As road engineering projects place increasing demands on the quality of hot-mix asphalt, asphalt mixing plants are also constantly innovating their technologies, becoming the core driving force for upgrading hot-mix asphalt production.

- High-precision weighing systemThe upgraded weighing system controls aggregate metering error to ±0.5% and asphalt metering error to ±0.1%, ensuring accurate formulation from the source.

- Energy-saving combustion technologyIt can be adapted to various fuels such as natural gas, fuel oil, heavy oil, and pulverized coal. By optimizing the combustion path, it reduces energy consumption and pollutant emissions.

- Recycled Material Processing TechnologyBy using a high-temperature preheating device to enhance the activity of recycled materials and combining it with a precise metering system to achieve a high proportion of addition, some advanced mixing plants can already achieve a 70% recycled material blending ratio.

- Warm-mixing agent addition technologyIntegrating a warm mix additive system into an asphalt mixing plant can reduce the production temperature of hot mix asphalt by 20-50℃, saving energy and improving the construction environment.

- Intelligent Control SystemThe system adopts a fully automatic control system, which enables real-time adjustment of production parameters. With the addition of remote monitoring, managers can keep track of the mixing plant’s operating status at any time and handle any abnormalities promptly.

Environmental Protection and Sustainable Development Measures

Modern asphalt mixing plants are no longer synonymous with “high pollution and high energy consumption.” Through a series of environmental protection technology upgrades, they have become the core guarantee for the green production of hot-mix asphalt.

In addition to a highly efficient dust treatment system, asphalt mixing plants are also equipped with asphalt flue gas condensation recovery and incineration treatment devices to convert harmful gases generated during the production process into harmless substances. The widespread adoption of high-proportion RAP recycling technology has significantly reduced the consumption of virgin aggregates and asphalt, reducing the pressure on resource extraction. The extensive application of warm mix asphalt (WMA) technology has not only reduced production energy consumption but also reduced carbon emissions and harmful gas emissions, making hot mix asphalt production more in line with the concept of sustainable development.

Key Points of Quality Control and Testing

Asphalt mixing plants are far more than just production lines; they are the “nerve center” and “safety gate” for hot-mix asphalt quality control. Their comprehensive, multi-dimensional testing system creates a closed-loop control system from raw material intake to finished product delivery, ensuring that every batch meets engineering standards. During the dynamic production process of hot-mix asphalt, the mixing plant’s intelligent testing system acts like a “precision radar,” capturing key performance indicators and basic parameters of the mixture in real time, providing a scientific basis for production adjustments.

Among these measures, for the core mechanical properties of the mixture—Marshall stability and flow value—the mixing plant will periodically extract samples using a dedicated sampling device to simulate road load-bearing conditions for testing. This ensures that the hot-mix asphalt has sufficient resistance to damage while also possessing appropriate flexibility when bearing vehicle loads, preventing excessive rigidity that could lead to cracking. Rutting dynamic stability testing focuses on high-temperature stability, simulating repeated vehicle rolling under high summer temperatures to assess the mixture’s ability to resist permanent deformation, which directly relates to the road’s service life during the hot season. Residual stability and freeze-thaw splitting strength tests are key to measuring water stability. The former reflects the ability to resist water damage through changes in strength after saturation, while the latter simulates freeze-thaw cycles to ensure that roads are less prone to loosening, peeling, and other defects in rainy, snowy, and icy areas. Meanwhile, the mixing plant continuously monitors fundamental parameters such as aggregate gradation, asphalt-aggregate ratio, and void ratio of the mixture using high-precision sensors and automated analysis systems. Minor deviations in aggregate gradation are captured in real time to prevent the pavement structure from becoming loose or overly dense due to an imbalance in the ratio of coarse to fine aggregates. Precise control of the asphalt-aggregate ratio is crucial to preventing pavement bleeding or asphalt deficiency; the mixing plant’s asphalt metering system dynamically adjusts based on the test data, strictly controlling the error within ±0.1%. The void ratio directly affects the pavement’s density and durability; if it exceeds the standard range, the mixing plant immediately feeds back to the control system, correcting it by adjusting parameters such as mixing time and temperature, ultimately ensuring that every batch of hot-mix asphalt meets the stringent requirements for road paving.

The “Heart” of Modern Road Construction

From the precise proportioning of raw materials to the quality control of finished products, the entire manufacturing process of hot-mix asphalt relies on the stable operation of the asphalt mixing plant. An efficient, environmentally friendly, and intelligent asphalt mixing plant is the fundamental prerequisite for ensuring the durability, safety, and comfort of every kilometer of road, supporting the extension and upgrading of the transportation network with industrial precision.

In the future, with the continuous advancement of technology, asphalt mixing plants will develop towards higher recycling ratios, lower energy consumption, and more comprehensive digitalization, continuously promoting the greening and intelligent upgrading of hot-mix asphalt production, injecting stronger momentum into modern road construction, and safeguarding the smooth and reliable operation of every transportation artery.