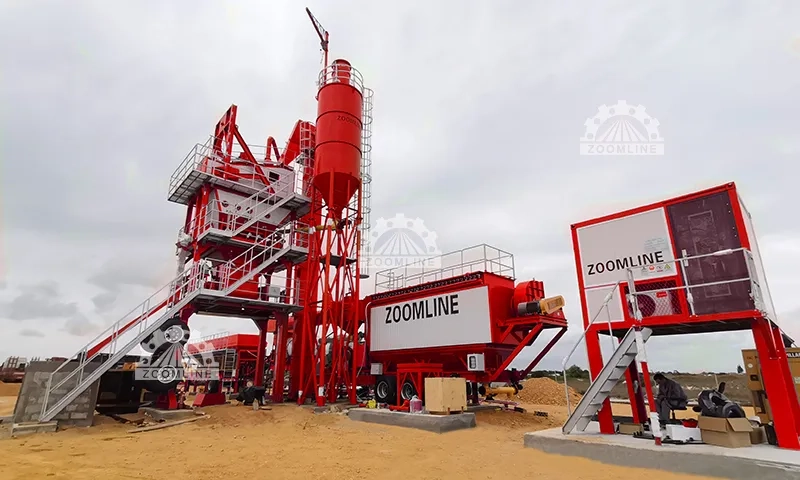

A mobile asphalt mixing plant is a modular asphalt mixture production equipment that can be quickly assembled, disassembled, and relocated. Its core function is to heat and mix raw materials such as sand and gravel aggregates, asphalt, and fillers in a specific ratio to produce asphalt mixtures that meet road construction standards. Compared with traditional stationary mixing plants, it is characterized by “convenient mobility and rapid commissioning.” Through its trailer-mounted structure design, it achieves flexible relocation between different construction sites, becoming an indispensable key piece of equipment in modern road construction.

The main differences between the two lie in three dimensions: basic requirements, relocation capability, and applicable scenarios. In terms of basic engineering, fixed batching plants require large reinforced concrete foundations, involving complex civil engineering construction; mobile batching plants, on the other hand, do not require large-scale infrastructure construction, only a leveled and compacted site for installation. Regarding relocation capability, fixed batching plants are difficult to move once built, while mobile equipment, through modular disassembly, can be transported by standard trucks, enabling rapid relocation across regions. In terms of applicable scenarios, fixed plants are more suitable for long-term, large-scale road projects or centralized production bases; mobile plants are precisely matched to short-term projects, dispersed construction sites, and emergency repair needs, with significant advantages, especially in remote areas and mountainous road construction.

In recent years, my country’s highway network construction has extended to counties and covered rural areas. Simultaneously, the number of decentralized projects such as old road reconstruction and municipal maintenance has increased, highlighting the drawbacks of traditional fixed asphalt mixing plants: “long-distance material supply and high transportation costs.” Furthermore, driven by strategies such as the Western Development Strategy and Rural Revitalization, road construction projects in remote areas have surged, placing higher demands on the mobility and adaptability of equipment. Mobile asphalt mixing plants, with their rapid commissioning and flexible relocation capabilities, effectively solve the core pain point of “materials following the work,” significantly reducing temperature losses and costs during long-distance asphalt mixture transportation. Therefore, their market demand continues to rise.

Compared to the months-long installation cycle of stationary mixing plants, mobile equipment, with its plug-and-play modular design, can reduce installation time to within a few days. Its functional modules (such as cold aggregate bins, drying drums, and control rooms) are pre-assembled at the factory, requiring only simple on-site procedures like positioning and connection of pipelines. This significantly shortens the time from equipment arrival to formal production, effectively mitigating the risk of construction delays, making it particularly suitable for urgent projects with tight schedules.

Most mobile asphalt mixing plants adopt a trailer-mounted structure, allowing them to be directly towed by standard freight trucks without the need for specialized transport equipment, significantly reducing logistical complexity. Whether for short-distance relocation during urban road maintenance or equipment migration for major cross-regional projects, efficient and convenient transportation is achieved. This mobility enables the equipment to precisely match the needs of multiple dispersed construction sites, avoiding the problem of limited service range at a single site.

Cost advantage is one of the core competitive advantages of mobile equipment. In terms of basic costs, it eliminates the large-scale civil engineering expenses required for fixed stations; in terms of labor costs, modular installation and automated control reduce the number of on-site construction and operation personnel; and in terms of transportation costs, it achieves double savings—it reduces the logistics expenses of relocating the equipment itself, and because it can be built at nearby stations, it avoids the fuel and haulage costs of transporting asphalt mixtures from long-distance fixed stations. The cost savings are particularly significant in large-scale road projects.

Mobile concrete mixing plants possess exceptional environmental adaptability, enabling stable operation in various scenarios, from urban redevelopment projects requiring both compact space and minimal disruption, to mountainous highway construction (complex terrain and inconvenient transportation), and even rural road paving (with weak infrastructure). Their adaptability to terrain and climate, along with the ability to flexibly adjust production scale based on project output, makes them a “universal tool” for diverse road construction scenarios.

Unlike fixed stations, which have high requirements for infrastructure such as water, electricity, and site, mobile equipment only requires basic water and electricity supply and a flat site to operate normally. This minimal infrastructure requirement gives it a natural advantage in short-term rental projects and small to medium-sized road maintenance projects, as it eliminates the need to invest a lot of resources in building supporting facilities for the project, effectively improving the return on investment.

Before purchasing, a comprehensive analysis of the project’s core requirements is necessary: In terms of output, the hourly output requirement of the equipment needs to be determined by combining the average daily construction volume and the total project volume; in terms of project duration, short-term projects should prioritize equipment with faster disassembly and assembly speeds, while long-term projects can balance stability and capacity; in terms of material requirements, the gradation characteristics of local aggregates, asphalt type (such as modified asphalt or ordinary asphalt), and fuel supply (diesel, heavy oil, etc.) need to be clearly defined to ensure that the characteristics of the equipment and raw materials are matched.

Production capacity selection should follow the principle of “matching project scale and reserving reasonable redundancy”. Equipment with a capacity of 60-80 TPH (tons/hour) is suitable for small and medium-sized projects such as rural roads and municipal maintenance, with a daily output capable of meeting the demand for 1000-2000 tons of mixed materials. Equipment with a capacity of 100-120 TPH is suitable for medium-sized projects such as county-level highways and industrial park roads, balancing capacity and flexibility. Large-scale equipment with a capacity of 140-160 TPH is designed for large-scale projects such as highway and main road reconstruction, enabling continuous and efficient production and avoiding delays in construction progress due to insufficient capacity.

When comparing mainstream brands and models, four core dimensions should be considered: First, the quality of core components, focusing on the material thickness of the drying drum, the energy efficiency of the burner, and the stability of the control system (such as the response speed of the PLC control system); second, after-sales service, examining the brand’s service network coverage in the project location, its ability to supply vulnerable parts, and its fault response time; third, user reputation, understanding the equipment’s failure rate and capacity achievement rate in actual construction through industry case studies; and fourth, customization capabilities, as some projects require special configurations (such as environmental upgrades and recycled material addition systems), confirming whether the brand supports personalized customization.

The equipment budget should cover purchase costs, transportation costs, installation and commissioning costs, inventory costs for consumable parts, and initial operation and maintenance costs. Cost-effectiveness analysis should not only consider the initial price but also the total lifecycle cost: low-priced equipment may have issues such as frequent replacement of consumable parts and high energy consumption, resulting in higher long-term maintenance costs; while well-known brand equipment, although requiring a higher initial investment, has advantages in stability and energy efficiency, thus reducing long-term costs. It is recommended to evaluate cost-effectiveness using the “unit output cost” (total investment ÷ expected total output) indicator.

By reviewing local transportation departments’ annual construction plans and project information from bidding platforms, and considering regional economic development trends (such as industrial park construction and new town development), the total number of road construction projects for the next 1-3 years can be predicted. Emphasis should be placed on government-led public welfare projects and transportation network upgrade projects, as these projects typically have stable construction periods and guaranteed funding, making them the core target market for equipment investment.

The survey investigated the distribution (stationary and mobile), production capacity, service area, and price levels of existing concrete mixing plants within the surveyed area. Analysis revealed market gaps: for example, stationary plants in a certain area are concentrated around cities, leaving service gaps in remote towns; or existing equipment is mainly low-capacity, lacking large-scale mobile equipment with capacities of 140-160 TPH. Focusing on these gaps can effectively enhance the market competitiveness of equipment.

Raw material supply directly impacts production costs and efficiency, necessitating an assessment of the supply radius for various raw materials: For stone, quarries within 50 kilometers of the construction site should be selected to ensure controllable transportation costs; for asphalt supply, the storage capacity and delivery cycle of local refineries or distributors must be confirmed to avoid production stoppages due to asphalt shortages; for fuel, the distribution of gas stations or fuel delivery services should be examined, prioritizing partners with stable supply and favorable prices. Generally, it is recommended that the overall supply radius for all raw materials be controlled within 100 kilometers.

Investment payback period calculation requires clarifying two core elements: revenue and costs. Revenue includes the unit price of the mixed material, the estimated annual output, and the number of projects undertaken. Costs cover equipment depreciation (or rent), raw material costs, labor costs, energy costs, operation and maintenance costs, and taxes. The payback period is calculated using the formula “Investment Payback Period = Total Investment ÷ (Average Annual Total Revenue – Average Annual Total Cost)”. Typically, a reasonable payback period for a mobile mixing plant is 1-3 years. If it exceeds 3 years, the project feasibility needs to be reassessed.

An ideal site for a construction project should meet the following eight conditions: First, convenient transportation, close to main roads or construction access roads to facilitate the transport of raw materials and finished products; second, flat terrain with a slope of no more than 3% to reduce site leveling costs; third, good drainage to avoid water accumulation during the rainy season affecting equipment operation; fourth, stable water and electricity supply, with the conditions for connecting to industrial power, and water sources can be municipal water supply or self-supplied wells; fifth, far away from environmentally sensitive areas (such as water sources and nature reserves); sixth, the land use designation should conform to industrial use to avoid compliance risks; seventh, no densely populated residential areas nearby to reduce noise and dust complaints; and eighth, a moderate distance from the main construction site to control transportation costs.

Asphalt mixtures need to be maintained at a certain temperature during transportation (usually not lower than 130℃), as excessively low temperatures will affect paving quality. Considering the transportation time and temperature loss patterns, the optimal transportation radius between the mixing plant and the paving site is 30-80 kilometers. Within this range, efficient transportation can be achieved using ordinary engineering vehicles, ensuring mixture quality while controlling transportation costs. If the distance exceeds 80 kilometers, refrigerated transport tankers are required, which will significantly increase transportation costs.

According to the “Emission Standard for Environmental Noise at the Boundary of Industrial Enterprises,” the distance between a concrete mixing plant and residential areas should be no less than 500 meters during nighttime operation and no less than 300 meters during the day. Site selection requires on-site surveys and map measurements to ensure a safe distance from residential areas, with priority given to downwind locations to minimize the impact of dust on residents’ lives. If proximity to residential areas is unavoidable due to constraints, sound insulation facilities and high-efficiency dust removal equipment must be installed in advance, and communication with local residents must be conducted.

Regarding electricity, it is necessary to confirm whether the local power grid can provide the voltage level (usually 380V industrial power) and power load required for the equipment. If necessary, a backup generator should be provided to deal with sudden power outages. The water source must meet the needs of production water (such as drum cooling and dust removal) and domestic water, and the water quality must meet industrial water standards. For fuel supply, a long-term supply agreement should be signed with local distributors to ensure a stable supply of fuels such as diesel and heavy oil, and the accessibility of fuel transportation channels should also be investigated.

The site area needs to be determined based on the equipment’s production capacity. Equipment with a capacity of 60-80 TPH requires at least 5 mu (approximately 0.33 hectares), while equipment with a capacity of 140-160 TPH requires more than 10 mu (approximately 0.67 hectares). Functional zoning should follow the principles of “smooth workflow, safety, and efficiency,” dividing the area into equipment installation area, raw material storage area (aggregate silos, asphalt tanks), finished product storage area, transport vehicle dispatching area, office and living area, and safety buffer zone. The raw material storage area must have adequate rain and moisture protection measures, and the transport dispatching area must ensure orderly vehicle entry and exit to avoid congestion.

The site geology must have good bearing capacity; the foundation bearing capacity of the equipment installation area should not be less than 150 kPa to avoid settlement during equipment operation. A geological survey must be conducted before site selection. If the site is a soft soil foundation, reinforcement measures such as replacing with crushed stone and laying steel plates must be taken in advance. At the same time, areas with geological disaster risks such as faults and landslides must be avoided to ensure site safety and stability.

Strictly avoid all environmentally sensitive areas, including drinking water source protection areas, nature reserves, scenic spots, and ecological red line areas. Before selecting a site, consult the local environmental protection department regarding regional environmental planning to obtain clear environmental access opinions, avoiding project failure to pass environmental impact assessment approval due to improper site selection. If the project is located in an area with strict environmental control, higher-level environmental protection equipment must be installed to ensure emissions meet standards.

The land use must be clearly defined as industrial land or temporary construction land, avoiding the use of agricultural land or ecological protection land to prevent legal risks; the rental cost must be combined with the regional land price level, and the rent payment method and increase mechanism must be clearly defined with the land owner; the lease contract must clearly specify the lease term (which should cover the entire project cycle and reserve a certain buffer period), site maintenance responsibility, demolition compensation clauses and liability for breach of contract to avoid disputes later.

Environmental impact assessment (EIA) approval is a prerequisite for plant construction. A professional agency must be commissioned to prepare an EIA report, which must then be submitted to the local environmental protection department for approval. After approval, a discharge permit must be applied for based on the equipment’s emission type (exhaust gas, noise, solid waste), specifying emission limits and monitoring requirements. During operation, regular self-monitoring must be conducted, and monitoring reports must be submitted to the environmental protection department to ensure emissions meet standards.

Bring the site lease agreement, legal representative’s identification, and other materials to the local market supervision department to apply for a business license, clearly defining the business scope (e.g., “production and sale of asphalt mixture”). Then, go to the tax department to register for tax, determine the tax types and rates, and fulfill tax obligations in accordance with the law. If it is a sole proprietorship or partnership, an additional cooperation agreement is required.

If the construction of the site involves permanent buildings (such as office space or equipment foundations), a building planning permit must be applied for from the planning department, specifying the location, area, and structure of the buildings. If site leveling, pipeline laying, or other construction activities are involved, a construction permit must be applied for from the construction department to ensure that the construction activities are legal and compliant. If it is a temporary site construction, a temporary construction permit is required.

To apply for a safety production license from the local emergency management department, several conditions must be met before application: establishing a sound safety production management system, appointing a full-time safety officer, providing safety training to employees, and equipping the site with standard safety protection facilities and fire-fighting equipment. The emergency management department will conduct an on-site inspection of the site’s safety conditions and the establishment of its systems; the license will only be issued after the standards are met.

Asphalt and fuel oil are classified as hazardous chemicals and require a hazardous chemicals operation license from the local emergency management department. The application must include a site safety assessment report, a hazardous chemicals storage facility acceptance report, safety management regulations, and hazardous chemicals operation qualification certificates for all personnel. During storage, strict adherence to hazardous chemicals storage regulations is mandatory, along with clearly visible warning signs and the provision of spill response equipment.

If you choose to build your own transport fleet, you will need to obtain road transport permits for the vehicles, and the drivers must hold the corresponding professional qualification certificates. If you entrust a third party with transport, you must confirm that the partner has legal transport qualifications. In addition, if the equipment relocation involves oversized transport, you will need to apply for an oversized transport permit from the transportation department and plan a reasonable transport route and time.

While ISO 9001 quality management system certification is not mandatory, it is crucial for enhancing a company’s competitiveness. Certification demonstrates that a company’s production processes and quality control meet international standards, which helps in securing large-scale engineering projects and establishing long-term partnerships. The certification process requires improving quality management systems and standardizing raw material inspection, production process control, and finished product inspection procedures.

Upon arrival, the site is first leveled using bulldozers and rollers to flatten and compact the ground, ensuring the slope does not exceed 3%. Then, according to the equipment installation drawings, a concrete cushion layer (with a thickness of not less than 20cm) or steel plates are poured or laid at the equipment support points to enhance the bearing capacity of the foundation. At the same time, drainage ditches are dug to ensure that rainwater can be drained quickly and to prevent water accumulation on the site.

Transport the trailer-mounted equipment modules to the designated location and use a crane to precisely position each module; adjust the equipment level and ensure the error does not exceed 2mm/m using a laser level; then unfold the equipment support legs, place thick steel plates at the bottom of the support legs, and fix the support legs to the concrete pad with anchor bolts to prevent the equipment from shifting during operation.

Install cold material feed hoppers, ensuring clear separation of each hopper and accurate docking with the belt conveyor; then install the inclined belt conveyor, adjusting its tension and flatness to prevent deviation and slippage during operation; install guardrails on both sides of the belt conveyor and set up emergency stop buttons to ensure operational safety.

Use a crane to hoist the drying drum onto the support frame, and adjust the installation angle of the drum (usually 3-5°) to ensure that the material can flow smoothly; then connect the burner to the feed end of the drum, seal the gaps at the connection to prevent air leakage; connect the fuel line of the burner to the ignition system, and conduct a pressure test to ensure that there is no leakage.

Select either a baghouse dust collector or a wet scrubber according to environmental protection requirements. Hoist the dust collector to the designated location and connect it to the exhaust port of the drying drum through a pipe. Ensure that the pipe connection is tight to reduce dust leakage. Install the dust collector’s pulse cleaning system and ash discharge device, and adjust the cleaning cycle and ash discharge speed to ensure dust removal efficiency.

Install the asphalt tank and the heat transfer oil heater at the edge of the equipment area, ensuring that the distance between them meets safety standards (not less than 5 meters); connect the heating pipelines of the heat transfer oil heater and the asphalt tank, and conduct a pressure test to ensure smooth circulation of the heat transfer oil; install the finished product silo, adjust the unloading height of the silo to match the feed inlet of the transport vehicle, and install a level gauge to monitor the silo inventory in real time.

Position the control room module and connect the control room to each piece of equipment, including power and control cables. Cables must be laid in conduits for protection to prevent damage from crushing. Install the distribution box and grounding system to ensure that the grounding resistance is no greater than 4Ω to prevent electric shock accidents. Debug the control system to ensure that the operating parameters of each piece of equipment can be accurately displayed and controlled in the control room.

Complete the connection of asphalt delivery pipelines and fuel pipelines, seal the joints with sealant, and conduct airtightness tests; organize the cable lines and mark them for easy future maintenance; connect the compressed air system to provide air supply for pneumatic valves, dust collector cleaning systems, etc., and adjust the air pressure to 0.6-0.8MPa; finally, conduct a comprehensive inspection of all pipelines and cables to ensure that the connections are firm and leak-free.

Before no-load operation, the following items must be checked: whether the connecting bolts of all equipment components are tightened; whether the lubricating oil in rotating parts such as bearings and gears is sufficient; whether the rotation direction of equipment such as belt conveyors and rollers is correct; whether the indicator lights and instruments of the control system are normal; whether the safety devices (such as emergency stop buttons and limit switches) are sensitive and effective; and whether the valves of the dust removal system and burner are in the closed position. The no-load operation time should be no less than 4 hours, with a focus on observing the stability of equipment operation and noise level.

According to the construction mix requirements, the discharge ratio of the cold material feed hopper was calibrated. By adjusting the speed of the variable frequency motors in each hopper, the discharge amount of aggregates of different specifications was controlled. The deviation between the actual discharge ratio and the design ratio was detected by the “weighing method” to ensure that the deviation does not exceed ±2%. At the same time, a screening test was conducted on the mixed material conveyed by the belt conveyor to verify whether the aggregate gradation met the design requirements. If there was a deviation, it was corrected by adjusting the opening of the hopper gate or the motor speed.

When calibrating the asphalt flow meter, the actual asphalt delivery volume must be weighed and compared with the flow meter display value to ensure that the error does not exceed ±1%. For temperature control calibration, different asphalt heating temperatures (such as 150℃ and 160℃) are set. After the temperature stabilizes, an infrared thermometer is used to detect the actual asphalt temperature, and the heating power of the thermal oil furnace is adjusted to control the deviation between the actual temperature and the set temperature within ±3℃.

During the first trial mixing of hot asphalt, raw materials were added according to the construction mix proportions. The outlet temperature of the drying drum was controlled at 160-180℃, and the asphalt temperature at 150-170℃. The mixing time was set to 30-45 seconds to ensure uniform mixing. After the trial mixing was completed, Marshall specimens were prepared and their stability, flow value, porosity, and other indicators were tested. If the indicators did not meet the requirements, the asphalt content or aggregate gradation needed to be adjusted until the standards were met.

A third-party testing agency was commissioned to test the environmental indicators of the equipment: the concentration of particulate matter emissions must comply with the “Emission Standard of Pollutants for Asphalt Industry” (GB 4915-2013), i.e., not exceeding 10 mg/m³; the noise level at the plant boundary must not exceed 65 dB(A) during the day and 55 dB(A) at night; production wastewater must be treated in a sedimentation tank before reuse and must not be discharged externally. If any test indicators exceed the standards, the parameters of the dust removal equipment must be adjusted in a timely manner and sound insulation facilities must be installed to ensure that emissions meet the standards.

Before disassembly, three preparatory tasks must be completed: First, a detailed disassembly plan must be developed, clearly defining the disassembly sequence of each module, responsible personnel, and safety precautions; second, all raw materials inside the equipment must be emptied, including aggregates in the cold material silo, asphalt in the asphalt tank, and fuel in the fuel tank, to prevent leakage during transportation; third, the equipment’s water and electricity supply must be cut off, all valves closed, and pipelines purged to prevent residual materials from solidifying and causing blockages. The shutdown procedure must be strictly followed according to the equipment manual to ensure the equipment is in a safe shutdown state.

A scientific disassembly sequence can improve efficiency and avoid damage to components. It is recommended to follow the principle of “from top to bottom, from outside to inside, and accessories before main body”: First, disassemble the external cables and instrument accessories of the control room; then disassemble the upper equipment such as the finished product silo and dust collector; next, disassemble the main equipment such as the drying drum and burner; finally, disassemble the lower equipment such as the cold material supply system and asphalt tank. During the disassembly process, large components should be numbered and marked to facilitate reinstallation.

Critical components require special protection: Circuit boards and instruments of the control system must be wrapped in moisture-proof film and placed in a special packaging box to avoid vibration and moisture; precision components such as bearings and gears must be coated with anti-rust oil and sealed with plastic film; conveyor belts must be cleaned, wound up, and secured with rope; dust collector bags must be stored separately to avoid dust contamination. Special packaging materials must be used when packing, and fragile parts should be padded with cushioning layers and marked with warning labels such as “Fragile” and “Here” or “This Side Up”.

Select the transport vehicle according to the weight and size of the components: small modules can be transported by ordinary trucks, while large components (such as drying drums and finished product silos) need to be transported by flatbed trailers; when loading, the principle of “heavy on the bottom and light on the top, and evenly distributed” should be followed to avoid the vehicle’s center of gravity shifting; use wire ropes, tensioners, etc. to fix the components to the truck bed, and put rubber pads at the contact points between the wire ropes and the components to prevent wear on the surface of the components; when the transport height exceeds 4.5 meters, an oversized transport permit is required.

The advantages of a professional dismantling and assembly team lie in its high efficiency and rich experience, which can avoid equipment damage. This makes them suitable for large equipment or projects requiring urgent relocation, but their costs are higher (typically 1%-2% of the equipment value). Having your own team is less expensive and suitable for smaller equipment or projects requiring frequent relocation, but it requires professional training to ensure the team possesses dismantling skills and safety awareness. Companies can choose the appropriate dismantling and assembly model based on the project’s urgency, equipment complexity, and budget. A hybrid model combining a professional team and an in-house team can also be adopted to reduce costs while maintaining efficiency.

Currently, the fastest relocation record for small mobile mixing plants in the industry is 3 days (1 day for dismantling, 1 day for transportation, and 1 day for installation), while the fastest relocation record for large equipment is 7 days. Suggestions for optimizing relocation efficiency include: 1) completing foundation preparation at the new site in advance to shorten installation time; 2) pre-assembling equipment modules to reduce on-site connection procedures; 3) equipping dedicated dismantling and assembly tools and transport vehicles to avoid waiting; and 4) establishing a standardized relocation process manual to clearly define the time nodes and division of responsibilities for each step.

A strict inspection procedure must be performed before starting the machine each day: check whether the connecting bolts of each component are loose; whether the lubricating oil level and quality are normal; whether the fuel and asphalt reserves are sufficient; whether there are any leaks in the water pipes and oil pipes; whether the parameter settings of the control system are correct; and whether the safety devices (such as fire extinguishers and emergency exits) are intact. After the inspection is completed, fill out the “Pre-Start Inspection Record Form”, and start the machine only after the person in charge has signed and confirmed it.

Establish a raw material control mechanism of “mandatory inspection upon arrival, rejection of substandard materials”: When aggregates arrive, their particle size distribution, mud content, and crushing value must be tested, with each batch consisting of 2000 tons; when asphalt arrives, its penetration, ductility, and softening point must be tested, with each batch consisting of 500 tons; fuel oil must be tested for its calorific value and flash point to ensure combustion efficiency and safety. Inspection results must be recorded and archived; substandard raw materials must be returned promptly and are strictly prohibited from being used in production.

Key quality indicators must be monitored in real time during production: For temperature, the outlet temperature of the drying drum and the asphalt temperature must be checked hourly to ensure they meet construction requirements; gradation control is achieved through real-time monitoring of hot aggregate gradation using an online sieve analyzer, with samples taken every 4 hours for laboratory testing; the asphalt-aggregate ratio must be continuously monitored using an infrared spectrometer, with samples taken from each batch of mixture for testing to ensure the asphalt-aggregate ratio deviation does not exceed ±0.3%. If any abnormal indicators are detected, equipment parameters must be adjusted immediately, and production of substandard mixtures must be stopped.

Finished material silos must be equipped with insulation layers to ensure that the temperature drop of the mixture does not exceed 5°C/hour during storage; the mixture in the silo must follow the “first-in, first-out” principle to avoid clumping caused by long-term storage; the mixture stored for more than 24 hours must be retested for temperature and quality, and if it does not meet the requirements, it must not be used for paving; the bottom of the silo must be cleaned regularly to prevent residual mixture from accumulating and hardening, which would affect the smooth unloading.

Fleet dispatching needs to achieve “supply and demand matching and route optimization”: Based on the demand at the paving site, the number and frequency of transport vehicles should be rationally arranged to avoid situations where “materials wait for vehicles” or “vehicles wait for materials”; GPS positioning systems should be used to monitor vehicle trajectories and plan the shortest transport routes to avoid congested sections; vehicle transport ledgers should be established to record information such as the load amount, transport time, and unloading location of each vehicle for cost accounting and performance evaluation; and drivers should be regularly trained to improve safety awareness and driving efficiency.

Daily maintenance includes: cleaning dust and debris from equipment surfaces; checking lubricating oil levels and replenishing as needed; cleaning the dust collector hopper; and checking the belt tension of the conveyor belt. Weekly maintenance includes: tightening connecting bolts on all components; checking bearing temperature and vibration; cleaning the fuel filter and air filter; and calibrating temperature instruments and flow meters. Monthly maintenance includes: checking the gearbox oil quality and replacing lubricating oil if necessary; checking the sealing of asphalt pipelines and replacing aged seals; and conducting a comprehensive commissioning of the control system. Annual maintenance includes: disassembling and inspecting core components such as the drying drum and burner; replacing severely worn parts (such as belts and bearings); and performing comprehensive rust removal and anti-corrosion painting on the equipment.

Establish a consumable parts inventory ledger, specifying the minimum inventory level for each component (e.g., 10 sets of cloth bags and 5 sets of bearings). When the inventory falls below the minimum value, promptly initiate the procurement process. Consumable parts should be stored separately and protected against moisture and dust. For example, cloth bags should be stored in a dry and ventilated warehouse, and bearings should be stored in sealed packaging boxes. Sign long-term supply agreements with suppliers to ensure that consumable parts can be delivered quickly and avoid equipment downtime due to part shortages.

Burner maintenance requires regular cleaning of carbon deposits in the nozzles and furnace to avoid affecting combustion efficiency; checking the gap and wear of the ignition electrodes and adjusting or replacing them as needed; and monitoring fuel pressure and atomization to ensure complete combustion. For energy-saving retrofits, ordinary burners can be replaced with low-NOx burners, reducing nitrogen oxide emissions and improving thermal efficiency; installing waste heat recovery devices utilizes the waste heat from the drying drum to heat cold air or asphalt, reducing fuel consumption and typically achieving energy savings of 10%-15%.

Winter anti-freezing measures: After production stops, drain residual materials and accumulated water from asphalt and water pipelines to prevent them from freezing and cracking; insulating asphalt tanks and heat transfer oil furnaces, such as wrapping them with rock wool insulation layers, and turning on heating devices to maintain temperature if necessary; the hydraulic system of the equipment can be replaced with low-temperature anti-wear hydraulic oil. Summer high-temperature prevention measures: Install cooling fans or air conditioners for control rooms, motors, and other equipment; regularly check the water level and quality of the cooling system to ensure cooling effect; avoid prolonged full-load operation during the midday high-temperature period, and appropriately reduce production capacity if necessary.

High-risk operations include equipment hoisting, electrical maintenance, burner commissioning, and asphalt tank cleaning. Specific safety operating procedures must be developed: During hoisting operations, the tonnage and hoisting radius of the crane must be confirmed, a warning area must be set up, and unauthorized personnel are strictly prohibited from entering; before electrical maintenance, the power must be cut off and a “Do Not Operate” sign must be hung; when commissioning the burner, nitrogen purging must be performed first to prevent gas leaks from causing an explosion; when cleaning the asphalt tank, ventilation and replacement are required, the oxygen concentration inside the tank must be checked, and gas masks and protective gloves must be worn.

Based on the site area and equipment layout, fire protection facilities should be configured reasonably: two 4kg dry powder fire extinguishers should be provided for every 50 square meters of equipment installation area, asphalt tank area, and fuel storage area; fire hydrants should be installed to ensure that the pressure of the fire hydrants is not less than 0.1MPa and the range is not less than 15 meters; fire sand pits (with a volume of not less than 2 cubic meters) and fire blankets should be provided to extinguish fires caused by asphalt and fuel leaks; fire protection facilities should be inspected regularly to ensure that they are in good working order and that employees are proficient in their use.

Provide employees with standard-compliant personal protective equipment (PPE): operators must wear safety helmets, dust masks, noise-canceling earplugs, and high-temperature resistant gloves; electrical maintenance personnel must wear insulated gloves and insulated shoes; asphalt workers must be equipped with chemical protective suits and goggles; and workers at heights must wear safety belts. Establish a PPE requisition and inspection system, regularly replace aging and damaged protective equipment, and strictly prohibit employees from working without protective equipment.

New employees must undergo three levels of safety training—company-level, workshop-level, and job-level—before starting work. Company-level training focuses on explaining safety production laws and regulations and company safety systems; workshop-level training introduces the safety risks of the mixing plant and the location of fire-fighting facilities; job-level training involves on-site instruction from a mentor, explaining the safe operating procedures for the position, equipment risk points, and emergency response methods. The total training time for all three levels is no less than 24 hours. After completing the training, an assessment is required, and only those who pass the assessment can work independently.

Develop comprehensive emergency response plans, including emergency handling procedures for scenarios such as fire accidents, equipment failures, personnel injuries, and leaks; conduct at least one emergency drill per quarter, such as a simulated asphalt tank leak fire drill or a personnel electric shock rescue drill; clearly define the drill objectives, participating personnel, and their responsibilities before each drill, and conduct a summary and evaluation after each drill to analyze existing problems and optimize the emergency response plan. Through drills, improve employees’ emergency response capabilities and ensure a rapid and effective response to emergencies.

In recent years, the national environmental protection requirements for asphalt mixing plants have been continuously increasing. The “14th Five-Year Plan for Ecological and Environmental Protection” clearly states the need to strengthen the control of industrial waste gas and noise pollution and promote the green transformation of the asphalt industry. At the local level, many regions have introduced stricter local standards. For example, some provinces require that the concentration of particulate matter emissions from asphalt mixing plants not exceed 5 mg/m³ and the concentration of nitrogen oxide emissions not exceed 100 mg/m³. Enterprises need to closely monitor updates to local environmental protection policies, upgrade their environmental protection equipment in a timely manner, ensure compliant operation, and avoid production shutdowns and rectifications due to policy non-compliance.

Baghouse dust collectors offer advantages such as high dust removal efficiency (up to 99.9% or higher) and low dust emission concentration, making them suitable for areas with stringent environmental regulations. The collected dust can be recycled, reducing solid waste emissions. However, they require higher investment, the filter bags need regular replacement, and they are prone to condensation and clogging in humid environments. Wet scrubbers, on the other hand, offer lower equipment costs and can simultaneously remove dust and some harmful gases, making them suitable for high-temperature and high-humidity conditions. However, their dust removal efficiency is relatively low (approximately 95%), they generate wastewater requiring wastewater treatment facilities, and they are susceptible to freezing and cracking in cold regions. Companies should select appropriate dust removal equipment based on local environmental requirements, climate conditions, and cost budgets.

Waste gas treatment employs a combined approach of “burner optimization + dust removal + denitrification”: optimizing burner parameters to achieve complete combustion and reduce black smoke emissions; using high-efficiency bag filters to remove dust; and installing SCR denitrification devices to reduce nitrogen oxide emissions. Wastewater treatment implements a “zero-discharge” scheme: production wastewater is treated in sedimentation and filtration tanks and then reused for dust collector makeup or site sprinkling, with no external discharge; domestic sewage is treated in septic tanks and then entrusted to a third party for collection and transportation. Noise control adopts a “source control + transmission path blocking” approach: low-noise equipment is selected, and vibration damping devices are installed on motors, rollers, and other equipment; sound barriers are set up around the equipment, and the control room is decorated with soundproof materials to reduce the impact of noise on the surrounding environment.

Waste asphalt recycling technology is an important way to achieve green production. Its core involves crushing and screening waste asphalt mixtures from milled old road surfaces, then mixing them with new aggregates and asphalt in a specific ratio to produce standard recycled asphalt mixtures. This technology can save 30%-50% of the amount of new aggregates and asphalt used, reducing solid waste emissions. Depending on the heating method, it can be divided into two processes: hot recycling and cold recycling. Hot recycling is suitable for large-scale production and produces high-quality recycled mixtures; cold recycling is suitable for base course construction and requires lower equipment investment. Enterprises can equip themselves with recycled material addition systems according to project needs to achieve resource recycling.

Establish a refined cost accounting system: Fuel consumption per ton requires recording the fuel consumption and mixed material output for each batch of production, calculating unit fuel consumption, and reducing fuel consumption by optimizing burner parameters and increasing equipment load rate (target control at 6-8 kg/ton of mixed material); Electricity consumption per ton requires calculating the total electricity consumption during the production process and allocating it to each ton of mixed material, reducing electricity consumption by selecting energy-saving motors and rationally scheduling production time (avoiding peak electricity consumption periods) (target control at 8-10 kWh/ton of mixed material); Labor cost accounting requires calculating labor costs by job position, reducing the number of operators through automation upgrades, increasing per capita output, and reducing labor costs per ton.

Uptime directly impacts profitability. Improving uptime requires a three-pronged approach: First, expand business channels by establishing long-term partnerships with construction companies and participating in bidding processes to ensure stable orders. Second, strengthen equipment maintenance by reducing downtime through preventative maintenance, ensuring equipment availability is above 95%. Third, optimize production planning by proactively stockpiling raw materials and scheduling personnel to avoid downtime due to raw material shortages or insufficient staff. Typically, a 10% increase in uptime can boost profitability by 15%-20%.

Stone powder collected by dust collectors is an important byproduct that can be comprehensively utilized to generate revenue: it can be used as an admixture in cement production, or as a raw material in the production of concrete products and bricks; it can also be sold to road base construction units to improve soil compaction performance. By establishing stone powder sales channels, each ton can generate 50-100 yuan in revenue, which not only reduces solid waste disposal costs but also increases additional income and enhances the overall profitability of the project.

Common reasons for losses include: excessively high raw material procurement costs (lack of long-term cooperative channels), frequent equipment failures (inadequate maintenance), insufficient orders (weak market development capabilities), excessive energy consumption (outdated equipment or improper operation), and fines for safety and environmental accidents (weak compliance awareness). Recommendations to avoid these pitfalls: Sign long-term supply agreements with quarries and asphalt suppliers to lock in raw material prices; establish a comprehensive equipment maintenance system and conduct regular maintenance; build a market development team and strengthen communication with local transportation and municipal departments; upgrade energy-saving and environmentally friendly equipment and standardize operating procedures; strictly comply with safety and environmental regulations to avoid the risk of fines.

In the future, mobile asphalt mixing plants will evolve towards intelligent and unmanned operation. By introducing technologies such as the Industrial Internet and AI algorithms, remote monitoring and automatic control of the equipment will be achieved—managers can view equipment operating parameters and production progress in real time via a mobile app; AI systems can automatically adjust production parameters and optimize mix proportions based on raw material characteristics; unmanned operation will reduce human intervention, improve production accuracy and efficiency, and reduce safety risks. It is expected that intelligent equipment will dominate the market in the next 5-10 years.

The integration of warm-mix asphalt technology and plant-mixed hot recycling technology will become a key development focus. Warm-mix technology, by adding warm-mix additives, can reduce the production temperature of asphalt mixtures by 30-50℃, significantly reducing energy consumption and emissions; plant-mixed hot recycling technology enables the efficient recycling of waste asphalt. After integration, the equipment will possess the dual functions of “warm-mix production + recycling,” meeting environmental protection requirements while reducing raw material costs, representing an important direction for achieving green road construction.

In terms of environmental protection, the equipment will be equipped with more efficient dust removal, denitrification, and noise reduction systems to achieve near-zero emissions. Regarding efficiency, by optimizing equipment structure and adopting new materials, production efficiency will increase by 20%-30%, while energy consumption will decrease by more than 15%. In terms of miniaturization, smaller, faster-to-assemble micro-mobile mixing plants will be widely used to meet the needs of small projects such as rural roads and municipal maintenance. This development direction of “environmentally friendly, efficient, and miniaturized” will better adapt to the diversified needs of the future road construction market and promote the high-quality development of the asphalt mixing equipment industry.