In the modern road construction field, efficient, flexible and low-cost mode of operation has become the core demand, Mobile Drum Mix Plant has gradually become a temporary project by virtue of its unique advantages of rapid deployment and flexible transfer, The Mobile Drum Mix Plant, with its unique advantages of rapid deployment and flexible transfer, has gradually become the equipment of choice for temporary projects, municipal repairs and construction in remote areas. Whether it is for emergency repair of municipal roads or segmental paving of rural highways, mobile asphalt mixing plants can break the geographical limitations of fixed mixing plants and significantly improve construction efficiency. Among them, Zoomline Super Mobile Drum Mix Plant (ZAP-C series), as a benchmark product in the industry, highly integrates all the functions in a trailer, without complex foundation, and the installation and commissioning is completed quickly, which completely solves the pain points of inconvenient transferring and long commissioning period of traditional mixing plant. Today, we will fully analyze this Super Mobile Drum Mix Plant and see how it can help constructors efficiently produce high-quality hot mix asphalt and easily cope with all kinds of complex construction scenarios.

Super Mobile Drum Mix Plant is a new type of asphalt mixing plant based on the continuous drum mixing process, the core feature of which is that all the operating systems are integrated in the chassis of a single or double trailer, which can be directly transported by highway dragging, and it can realize the portable concept of “one truck is one plant”, combining mobile flexibility and production stability. It realizes the portable concept of “one vehicle is one plant”, which takes into account the flexibility of mobility and stability of production. Compared with the traditional fixed Drum Mix and Mobile Batch Mix, its advantages are particularly outstanding: no need to build foundations in advance, eliminating the need for tedious foundation construction; the whole system is highly integrated, so there is no need to split it up when transferring, and it can be restarted within a few hours of arriving at the site, dramatically shortening the start-up cycle.

As a high-efficiency equipment suitable for multiple scenarios, Mobile Drum Mix Asphalt Plant and Super Mobile Drum Mix Plant are essentially in the same category, with “mobility” as the core positioning, while the Zoomline ZAP-C series has upgraded the level of integration. The Zoomline ZAP-C series is a step up in integration. With typical capacities ranging from 20-200 t/h (from ZAP-C20M to ZAP-C200M), the Zoomline ZAP-C series can be precisely adapted to a wide range of scenarios, such as small and medium-sized road paving, pavement patching, and municipal pipeline roads. For example, in urban roads with high traffic flow and narrow construction space, the Super Mobile Drum Mix Plant can be deployed directly near the construction section to produce hot mix asphalt quickly, and then transfer it immediately after completing the emergency repair of the road surface, avoiding occupying the road for a long time and affecting the traffic, which is a perfect match for the rapid response to the repair needs of urbanized areas.

Zoomline Super Mobile Drum Mix Plant appearance is designed with “compactness and practicality” as the core, and the overall trailer-type layout is adopted, with the long drum as the core mixing component located in the middle of the plant. The overall structure is simple and neat, with the long drum as the core mixing component, located in the center of the plant, and equipped with folding cold bins, an integrated control room, and hydraulic legs on both sides, with a much smaller footprint than traditional mobile plants. This compact design makes it easy to enter narrow construction sites, city blocks and other areas that are difficult for conventional equipment to reach, especially suitable for densely populated urbanized areas with limited construction space.

In terms of design innovation, the equipment adopts a high-strength trailer chassis with strong load-bearing capacity, which can be adapted to the transportation needs of different road conditions, and the number of axles is set to 2-4 axles, which is in line with the road transportation standards of most regions in the world, and makes it convenient and safe for towing and moving. At the same time, the equipment is equipped with quick-connect interface, water, electricity, fuel and other pipelines can be quickly docked, without the need for professional technicians to cumbersome operation; hydraulic legs can automatically adjust the height, to ensure that the equipment can be placed stably on uneven sites, to provide a guarantee of efficient production.

Compared with traditional equipment, the Zoomline Mobile Asphalt Plant’s design advantage is also reflected in the “time-saving”: there is no need for large-scale lifting equipment to assist in the installation, and after positioning on the site, the operator only needs to complete the simple pipeline connection and parameter debugging, and then the production can be started, the shortest time from the arrival of the equipment on the site to the official production can be controlled. From the arrival of the equipment to the official production, the shortest time can be controlled within 4 hours, which greatly improves the construction efficiency, especially suitable for multi-point construction projects that require frequent transfer.

The high efficiency of Zoomline Super Mobile Drum Mix Plant (ZAP-C series) is inseparable from the precise cooperation of each core component, and each system has been optimized and designed, taking into account high efficiency, energy saving and environmental protection, as follows:

is equipped with folding cold aggregate silos, with a single silo volume of 4.5-8 m³, and multiple silos can be configured according to the construction requirements, realizing the separate storage and feeding of aggregates of different specifications. The system adopts frequency conversion feeding design, which can precisely adjust the feeding speed to ensure uniform and stable supply of aggregates and avoid fluctuation of asphalt mixture quality due to uneven feeding, and at the same time, the frequency conversion control can also effectively reduce the energy consumption, which is in line with the concept of green construction.

As the core component of the equipment, the drying/mixing drum adopts the optimized size of 1.2-2.2m in diameter and 3.8-8.5m in length, which can be flexibly matched according to the capacity demand. The drum adopts downflow or counterflow mixing process, the downflow process has high heating efficiency and is suitable for construction in low-temperature environment; the counterflow process is more energy-saving and environmentally friendly, which is in line with the requirements of the European Union and other regions with stringent environmental protection laws and regulations, and it can effectively reduce the emission of fumes and heat loss, and at the same time, ensure that the aggregates are dried uniformly, and the asphalt is coated sufficiently.

adopts high-efficiency energy-saving burner, with fuel consumption as low as ≤7 kg/t, much lower than the average level of the industry, which significantly reduces the operating cost. The system supports a variety of fuel types such as diesel, heavy oil, natural gas, etc., which can be flexibly switched according to the fuel supply situation in the construction area to meet the needs of construction in different regions. Meanwhile, the burner adopts intelligent temperature control technology with high thermal efficiency, which can accurately control the temperature in the drum to ensure the drying effect of aggregates and asphalt mixing quality, and part of the model can also be adapted with low-NOx combustion technology to further reduce the emission of nitrogen oxides and meet the stringent environmental standards.

is equipped with high efficient Baghouse system, the filter bag area covers 115-340 m², with high power induced draft fan, it can effectively filter the dust generated during the production process, the dust emission concentration meets the national and EU environmental standards, avoiding the construction environment pollution. The system is easy to maintain. The system is easy to maintain, the filter bag can be replaced quickly and the maintenance cost is low, which is especially suitable for the areas with high environmental protection requirements, such as the construction scenes in the EU countries, and also meets the requirements of air pollution control in urban areas.

integrates asphalt storage tank (Bitumen Tank), flow metering device and heating system. The asphalt storage tank can be selected with different volumes according to the demand, and the heating method supports three options of electric heating, thermal oil heating and direct-fired heating, which can adapt to different ambient temperatures to ensure that the asphalt always maintains a suitable flow state. Measuring system with high accuracy, can strictly control the asphalt dosage, to ensure that the ratio of asphalt mixture in line with the construction standards, to improve the quality of pavement paving, while the double-layer heat preservation structure design can effectively reduce the asphalt temperature drop, to avoid waste of resources.

is equipped with Drag Conveyor and 1.5 m³ small silo for finished products, which can realize fast discharging and temporary storage of finished asphalt to avoid segregation of the mixture. At the same time, 7.5-20 m³ silo can be selected according to the construction demand, further improving the storage capacity, adapting to the continuous construction demand, ensuring the smooth construction process and reducing the time of stopping and waiting for materials.

adopts PLC automatic control and manual control dual mode, with integrated operation cabin, the operation interface is simple and intuitive, the operator can get started after simple training. The system supports remote monitoring function, which can real-time view equipment operating parameters, production output, energy consumption, etc., which is convenient for managers to control remotely, timely detection and solution of problems in equipment operation, and reduce labor costs, while part of the model supports remote monitoring by cell phone APP, which further improves the convenience of operation.

One of the core advantages of Mobile Asphalt Drum Mix Plant is its continuous production process. The production process of Zoomline Super Mobile Drum Mix Plant has been optimized and designed to be simple and efficient without complicated operation. The specific process is as follows: firstly, the cold material enters the drying/mixing drum through the frequency conversion feeding system, and is heated by the burner in the drum to realize the drying and warming of the aggregate; then, the dried aggregate and the accurately measured asphalt and mineral powder synchronously enter the drum mixing area, and are fully mixed in the continuously rotating drum to ensure that the asphalt is evenly coated on the surface of the aggregate; lastly, the mixed hot asphalt is transferred to the final product silo through a scraper conveyor. Finally, the finished hot-mix asphalt is transported to the finished product warehouse through the scraper conveyor, which can be directly used for road paving or temporary storage, and the whole process is in continuous operation, which greatly improves the production efficiency.

For the characteristics of mobile operation, the process has been specially optimized: the combustion system adopts a rapid heating design, the equipment can quickly reach the temperature required for production after startup, reducing the preheating time; the drum adopts a thermal insulation structural design, low heat loss, to ensure that the temperature of the finished asphalt stabilized in the 130-160 ℃ within the standard range; the optimization of the integrated mixing zone design, effectively avoid the The optimized design of the integrated mixing zone effectively avoids the problem of segregation of the mixture and improves the quality of hot mix asphalt. In the production process, aggregate dryness, asphalt proportioning accuracy, fuel consumption are the three key parameters, Zoomline ZAP-C series through the precise control system, real-time regulation of these three parameters, to ensure that each batch of finished products are in line with the construction standards, and at the same time, the fuel consumption control of ≤ 7 kg / t, to achieve the dual goals of high efficiency and energy saving.

In order to show the advantages of Super Mobile Drum Mix Plant more clearly, we will make a comprehensive comparison with the traditional fixed Drum Mix (drum mixing plant) and Mobile Batch Mix (mobile intermittent mixing plant) to facilitate the construction party to choose the right plant for their needs. This is to facilitate the constructor to choose the right equipment according to their own needs:

| Comparison Items | Super Mobile Drum Mix plant | Stationary Drum Mix plant | Mobile Batch Mix plant |

| Mobility/Transfer speed | ★★★★★(one-truck dragging, restarting production in several hours) | ★(fixed installation, unable to transfer) | ★★★★(modular design, need to be transported by multiple trucks, split and transferred) |

| Installation Requirements | No foundation needed, can be debugged on site | Need to build special foundation in advance, long construction period | Site needs to be leveled, no foundation is needed but assembly and debugging are required. |

| Production Mode | Continuous drum mixing, high efficiency | Continuous drum mixing, stable production capacity | Intermittent mixing kettle, high proportioning accuracy, but slightly lower efficiency |

| Capacity range | 20-200 t/h, suitable for Small and medium-sized projects | Higher capacity, suitable for large-scale long-term projects | Comparable to or slightly higher than ultra-mobile |

| Investment and operating costs | low, no foundation investment, low fuel consumption, fast payback | medium, large foundation investment, stable operating costs | high, high cost of modular equipment, high transfer costs |

| Suitable scenario | Municipal maintenance, remote areas, frequent transfer, narrow construction sites | Large highways, long-term stable production projects | Municipal roads, highway section construction |

Entering 2026, environmental regulations are becoming increasingly stringent, especially in regions such as the European Union, where the emission requirements for asphalt mixing plants continue to increase. Super Mobile Drum Mix Plant has gradually become the mainstream choice in these regions due to its advantages of high efficiency in dust removal, low fuel consumption, and flexible transferability. Compared with the fixed mixing plant, it does not need to occupy fixed land and can be flexibly deployed according to the construction demand, which reduces the pressure of environmental protection approval brought by site occupation; meanwhile, the design of low emission and low noise can also be better adapted to the construction scenarios of cities, scenic spots and other construction scenes with high environmental requirements, which is in line with the industry’s green development trend.

In the face of all kinds of Mobile Asphalt Drum Mix Plant products on the market, how to choose a construction party to adapt to their own needs, cost-effective Super Mobile Drum Mix Plant?The core lies in the combination of their own construction needs, from capacity, The core is to combine their own construction needs, from the capacity, scene, configuration and other aspects of a comprehensive assessment, the specific can follow the following suggestions:

First of all, we need to clarify their own construction scenes and needs: for example, daily municipal maintenance, pavement patching, or small and medium-sized paving of the road is the main focus; the construction of the location of the frequent transfer, for example, need to be in a number of townships and neighborhoods switching between the operation; the construction of the site is restricted, such as urban areas of the narrow site. For example, narrow construction sites in urban areas; also consider the local environmental requirements, such as whether to meet the EU emission standards, in order to determine the core configuration needs of the equipment.

Capacity is the core indicator for equipment selection. The capacity of Zoomline ZAP-C series covers 20-200 t/h, which can be accurately matched according to the construction scale: 20-60 t/h models are suitable for small-scale pavement maintenance, community road paving, and other small batch production needs; 60-120 t/h models are suitable for small pavement maintenance, community road paving, and other small production needs; and 60-120 t/h models are suitable for small batch production. The 60-120 t/h model is suitable for medium-sized construction projects such as municipal roads and rural highways; and the 120-200 t/h model can meet the mass production needs of large sectional highways and industrial park roads. Avoid blindly pursuing high capacity, resulting in idle equipment and increased energy consumption, and do not affect the construction progress due to insufficient capacity.

The core configuration directly determines the production efficiency of the equipment, product quality and operating costs: drum type can be selected according to the needs of environmental protection, countercurrent drum is more energy-saving and environmentally friendly, suitable for environmental requirements of the region; dust removal system prioritizes the selection of bag-type dust removal, to ensure that the emissions meet the standards, and at the same time pay attention to the area of the filter bag and the ease of maintenance, reducing the cost of late maintenance; the fuel system is recommended to choose a multi-fuel switching model. Choose the model with multi-fuel switching to enhance the adaptability of the equipment; if the construction cycle is long and continuous production is required, a large-capacity finished goods warehouse can be selected to avoid stopping work and waiting for materials. In addition, the thermal efficiency of the burner, asphalt metering accuracy should also be focused on, directly affecting the construction quality and energy consumption.

When choosing the equipment, you should also consider the future upgrading of construction needs, such as whether it is possible to expand the construction scale, whether it is necessary to adapt to higher environmental protection standards, whether it is necessary to increase the RAP (Recycled Asphalt Pavement) inlet and so on. Zoomline Super Mobile Drum Mix Plant supports modularization and can be upgraded according to later needs by adding a finished product silo, a RAP processing system, a larger cold material bin, etc. without replacing the whole plant, which greatly reduces the long-term investment cost and meets the long-term development needs of the construction company.

Many builders will encounter some common questions when purchasing and using Super Mobile Drum Mix Plant, especially those who are using the mobile equipment for the first time, and are prone to fall into cognitive misunderstandings, the following answers to three of the most common questions:

Q1: Is it true that no foundation is needed for Super Mobile Drum Mix Plant installation? What do I actually need to prepare?

The answer is: It is true that you do not need to build the concrete foundation of traditional fixed mixing plant, but you need to prepare a level and solid site. The plant is equipped with hydraulic legs, which can be directly supported on level ground, but the site should be free from the risk of subsidence to avoid the plant shaking during operation, which will affect production safety and product quality. At the same time, the site needs to reserve space for equipment transfer, feeding and discharging to ensure that forklifts, dump trucks and other equipment can operate smoothly; if the ground is soft at the construction site, steel plates or gravel can be paved to enhance the load-bearing capacity of the ground, eliminating the need for complex foundation construction and truly realizing rapid deployment.

Q2: How long does it take to transfer equipment and restart production? How to avoid common problems?

The transfer of Zoomline Super Mobile Drum Mix Plant is extremely efficient. The complete plant can be transported by trailer without disassembling, and the transfer time mainly depends on the transportation distance. After arriving at the site, the operator completes the steps of hydraulic leg positioning, pipeline connection, parameter adjustment, etc. Under normal circumstances, the production can be restarted in 4-8 hours, and the fastest production can be realized in 3 hours. Common problems mainly include loose pipeline connection and improper parameter debugging, avoiding the following methods: carefully check the pipeline interfaces before transferring, and do a good job of fixing and protection; after arriving at the site, debugging is carried out in strict accordance with the operation manual, focusing on checking the parameters of the combustion system and the metering system to ensure that the equipment operates normally before starting the production, and at the same time, regular maintenance is carried out on the equipment to minimize the incidence of malfunctions.

Q3: Is baghouse dust collection enough under EU environmental protection requirements? Is the maintenance cost high?

Zoomline Super Mobile Drum Mix Plant is equipped with bag filter system, the filter bag area can be up to 115-340 m², with high efficiency induced draft fan, the dust emission concentration can be controlled within the EU environmental protection standard, and can be upgraded to high efficiency filter bag according to the demand, to further reduce the emission concentration, which is suitable for the EU and other environmentally stringent areas. It is suitable for the EU and other regions with strict environmental requirements. Low maintenance cost, the service life of the filter bag can be up to 1-2 years, depending on the construction environment and the frequency of use; the replacement of the filter bag is simple, no need for professional equipment, the operator can be completed; daily maintenance only need to regularly clean up the dust on the surface of the filter bag, check the status of the induced draft fan, without high maintenance costs, compared with other dust removal methods, bag filter is more suitable for mobile equipment, combining environmental protection and economic efficiency. Compared with other methods of dust removal, bag filter is more suitable for mobile equipment, taking into account the environmental protection and economy.

Among many Mobile Asphalt Drum Mix Plant brands, Zoomline Super Mobile Drum Mix Plant (ZAP-C series) can stand out and become the first choice of global builders because of its excellent product quality, perfect service system and rich experience in the industry, the specific advantages are as follows:

The biggest advantage of Zoomline Super Mobile series is its “ultra-high degree of integration”, which integrates all the systems of cold material supply, drying and mixing, asphalt supply, dedusting, and control into a single trailer, thus truly realizing the concept of “one trailer is one plant”; quick installation and installation of the ZAP-C series. A plant”; fast installation and transfer capacity, significantly shorten the commissioning cycle, reduce construction costs; fuel consumption as low as ≤ 7 kg / t, than the industry average to save 10% -15% of the fuel cost, long-term use can save a lot of operating expenses; high-efficiency bag-type dust removal system to ensure that the environmental protection standards, suitable for all kinds of stringent environmental protection scenarios around the world; At the same time, the high-strength chassis design can be adapted to the transportation of complex road conditions, whether it is the mountains of Peru, hot and humid areas in Thailand, or remote villages in Indonesia, all of them can operate stably.

Zoomline has rich global export experience, and its products have been exported to Europe, Africa, North America, Asia and other countries and regions, accumulating a large number of real successful cases, and its reputation is widely recognized: in Kenya, 40 t/h ZAP-C40M model is used for paving rural highways, fast production, flexible transfer, perfectly adapted to the construction needs of remote areas, which greatly improves the road paving demand, and improves the quality of road paving in the country. In Madagascar, the 60 t/h model is used for municipal road maintenance, which can quickly respond to the construction demand and transfer to the next construction site immediately after completing the road repair, effectively shortening the construction cycle; in Peru, the 120 t/h model successfully adapts to the complex mountain road conditions with its high-strength chassis, and its continuous and stable production has won the high praise of the local construction authorities. In addition, this series of equipment also successfully completed the construction tasks in the municipal emergency repair projects with the advantages of flexibility and high efficiency.

Zoomline has always insisted on quality as the core, the core components of the equipment are all made of international famous brands, and undergo strict quality testing to ensure the long-term stable operation of the equipment with a low failure rate; at the same time, it provides a full range of after-sales service, including equipment installation and debugging, operator training, remote technical support, supply of spare parts, etc., and there are service outlets in many regions around the world. At the same time, we provide a full range of after-sales service, including equipment installation and commissioning, operator training, remote technical support, parts supply, etc., with service points in many regions around the world, to ensure that the construction side in the use of the process of encountering problems, can get a rapid response and solution. Whether it is the quality of the product or after-sales service, Zoomline is committed to providing a full range of protection for the builder, so that the user can buy with confidence and use with peace of mind.

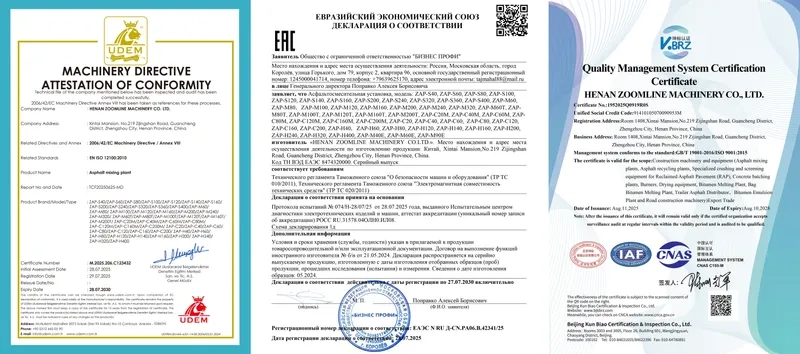

Zoomline Super Mobile Series Mobile Asphalt Drum Mix Plant has been plowing into the global market for many years, and has always been strictly controlling the quality of products by international standards. All of its ultra-mobile asphalt drum mixing plants have passed the certification of the three authoritative systems of CE, EAC, and ISO, and are equipped with relevant technology patents. All of our ultra mobile asphalt drum mixing plants have successfully passed the three authoritative systems of CE, EAC and ISO, and are supported by relevant technical patents.

ISO9001 quality management system certification, covering the whole process of product development, production, testing, after-sales service, to ensure that each piece of factory equipment meets the unified high-quality standards, from the selection of core components to the whole machine assembly and commissioning, all through a rigorous review, significantly reducing the failure rate of the equipment; CE certification signifies that the product is fully in line with the European Union’s safety, health, environmental protection and other relevant directive requirements, and can be freely entered into the European Union member states and regions that recognize the CE certification. CE certification indicates that the product is fully compliant with EU safety, health and environmental directives, and can freely enter the EU member states and regional markets that recognize CE certification, which is in line with the EU’s stringent environmental protection and safety standards; EAC certification ensures that the equipment can be compliant with the Customs Union countries such as Russia and Central Asia, which eliminates the need for additional compliance testing and shortens the cycle of entering the field of the equipment for overseas projects.

These authoritative certificates are not only a strong proof of the quality of Zoomline’s products, but also a direct reflection of the brand’s strength. Compared with similar products that have not obtained international certification, the Zoomline Super Mobile series does not need to invest in additional costs to carry out compliance rectification, and can be quickly adapted to meet the needs of the market in different regions of the world, whether it is Europe, Central Asia, Africa or Southeast Asia, to ensure that the equipment is compliant with the construction projects, and can also ensure that the equipment is compliant. Whether in Europe, Central Asia, Africa or Southeast Asia, the Zoomline Super Mobile series can ensure the compliant operation of the equipment and protect the overseas construction projects.

Zoomline Super Mobile series has been optimized locally to meet the construction needs of different regions. For example, to meet the requirements of narrow construction space and strict environmental protection, the equipment is compact in size and meets the emission standards, so it can respond to the needs of municipal emergency repair quickly; to meet the complex road conditions and construction environments in Peru, Thailand, Indonesia and other regions, it has been optimized for the design and fuel adaptability of the chassis to ensure that the equipment can meet the requirements of different regions and the road conditions. For the complex road conditions and construction environments in Peru, Thailand, Indonesia and other regions, the chassis design and fuel adaptability have been optimized to ensure the stable operation of the equipment in high temperature, high humidity, mountainous areas and other scenarios, thus truly realizing the adaptive service of “adapting to local conditions”.

Kenya 40 t/h project: accurately matching the needs of local rural road construction, realizing rapid start-up and efficient construction. With compact body, the equipment can flexibly travel through small rural roads, and can be quickly deployed without complex site formation. It is suitable for local simple fuels, which effectively solves the pain point of “difficult to enter the site and slow to put into operation” of the rural road construction, and provides support for the local transportation upgrading.

Madagascar 60 t/h project: adapted to local multi-region decentralized construction scenarios, achieving stable operation and efficient transfer. The equipment optimizes the mobile performance and stability, can easily cope with bumpy road surface, can be quickly disassembled and assembled without the need for large-scale lifting, and efficiently produces qualified asphalt mixtures after being put into operation, which is suitable for the local mobile construction needs.

Peru 120 t/h project: Relying on the high-strength customized chassis, the machine can easily cope with the complicated terrain and severe construction test. The equipment optimizes the chassis structure for the rugged terrain, adopts high-strength steel to strengthen stability, and adapts to the local easy-to-access fuels to maintain stable operation during the high-intensity construction, demonstrating the strong adaptability.

With the continuous upgrading of road construction technology and increasingly stringent environmental protection requirements, 2026

will move towards the direction of “more environmentally friendly, smarter, more efficient and more flexible”. In 2026, Mobile Asphalt Drum Mix Plant will develop in the direction of “greener, smarter, more efficient and more flexible”, and the core trends are mainly reflected in four aspects:

1.Lower emission, electric/hybrid power becomes the new direction. In line with the global green development concept, the future of ultra-mobile asphalt mixing plant will gradually launch electric or hybrid models to reduce fuel consumption, reduce emissions, while with more efficient dust removal system and low nitrogen burner, to further enhance the environmental performance, to adapt to the more stringent environmental standards, which is also one of the core trends of the industry development in 2026.

2.Higher RAP compatibility and resource recycling. Recycled asphalt pavement materials (RAP) reuse has become an industry hotspot, the future equipment will further enhance the RAP compatibility, can be directly recycled asphalt materials into the production of new materials, reducing waste of resources, reduce construction costs, while meeting the concept of sustainable development, some manufacturers have begun to research and development of microwave-assisted heating system to further enhance the efficiency of RAP regeneration.

3.The integration of intelligent monitoring to improve management efficiency. Intelligent upgrading will become the focus of the equipment will be integrated into a more advanced Internet of Things system to support real-time data collection, remote monitoring, fault early warning and other functions, management personnel can be cell phones or computers, anytime, anywhere, check the status of the equipment, production output, energy consumption, etc., to achieve accurate management, reduce labor costs, while intelligent diagnostic system can be early warning of equipment failure, reduce downtime.

4.Modularization upgrade, improve adaptability. Future equipment will further optimize the modular design, in addition to the conventional finished product warehouse, RAP entrance upgrade, will also introduce more personalized upgrade options, according to the specific needs of the construction side, flexible with different configurations, to achieve the “one machine for multiple uses”, while the modular design will also reduce the cost of maintenance and upgrading of equipment, extend the service life of the equipment! At the same time, the modularized design will reduce maintenance and upgrade costs and extend the service life of the equipment, which is suitable for the long-term development needs of the constructor.

In the pursuit of high efficiency, flexibility and environmental protection in road construction, Mobile Asphalt Drum Mix Plant has become the core equipment in the new era of construction, Super Mobile Drum Mix Plant has completely solved the pain points of traditional mixing equipment by virtue of its unique advantages, such as “no need for foundation, quick transfer, high degree of integration”, which is suitable for temporary projects, municipal maintenance, remote areas and other complex construction scenarios. Zoomline Super Mobile Drum Mix Plant (ZAP-C series), as a benchmark product in the industry, not only excels in capacity, configuration, and efficiency, but also adapts to localized scenarios, and meets the stringent environmental requirements of the European Union, etc. With its rich experience in environmental protection, Zoomline Super Mobile Drum Mix Plant (ZAP-C series) also meets the stringent environmental requirements of the European Union. With abundant global cases and perfect after-sales service, ZAP-C series has become the preferred brand of builders.

In 2026, with the continuous upgrading of technology, Super Mobile Drum Mix Plant and Drum Mix Asphalt Plant will develop in the direction of being more environmentally friendly, smarter and more efficient, and Zoomline will continue to innovate and launch products that better meet the market demand, helping global construction companies to reduce costs, improve efficiency and easily meet all kinds of road construction challenges. road construction challenges. If you are looking for a cost-effective mobile asphalt drum mixing plant that is suitable for multiple scenarios, the Zoomline ZAP-C series is definitely the right choice for you.