Within the production system of an asphalt mixing plant, the bitumen tank serves as the core equipment for storing and maintaining asphalt temperature. Its operational status directly impacts the plant’s overall production efficiency and the quality of the asphalt mixture. It must not only ensure asphalt maintains optimal flow-ability at the appropriate temperature but also prevent external contaminants from affecting asphalt quality. However, prolonged use often leads to issues like asphalt residue and carbonized deposits accumulating inside the tanks. Failure to clean these promptly can trigger a chain reaction of problems. Therefore, a thorough understanding of bitumen tank cleaning methods and precautions is crucial for the stable operation of asphalt mixing plants.

Bitumen tanks serve as the core equipment for storage, insulation, and material supply in asphalt mixing plants. Untimely cleaning allows residual asphalt to oxidize and carbonize inside the tank, reducing heating efficiency, increasing energy consumption, and compromising mixing quality. Impurities and degraded asphalt contaminate fresh materials, lowering asphalt quality and shortening road lifespan. Residue buildup may also clog pipelines and valves, causing equipment failures and increasing operational costs. Therefore, regular and thorough cleaning of bitumen tanks is essential for ensuring product quality and maintaining normal equipment operation.

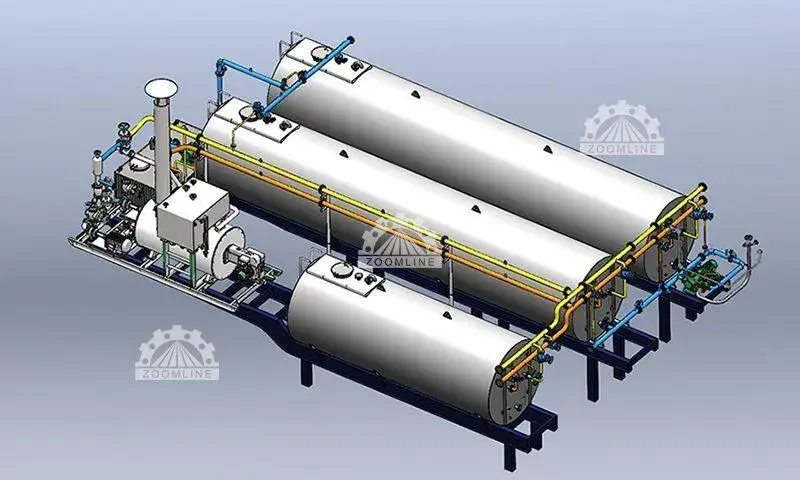

To clean bitumen tanks scientifically and efficiently, it is essential to thoroughly understand their structure and heating system, as different structural designs and heating methods directly impact cleaning procedures and techniques.

Bitumen tanks consist of an inner tank, heating coils, insulation layer, temperature sensors, and piping systems. The smoothness and integrity of the inner tank affect asphalt residue accumulation; residue on heating coil surfaces reduces heat transfer efficiency; damaged insulation causes unstable internal temperatures and increased residue buildup; temperature sensors provide data for heating regulation; and unobstructed piping ensures smooth asphalt flow.

Currently, bitumen tanks primarily employ three heating methods: thermal oil heating, direct flame heating, and electric heating. Each operates on distinct principles and imposes different requirements on cleaning procedures.

Thermal Oil Heating: Bitumen is heated by circulating preheated thermal oil through coils. This method provides relatively stable and uniform temperatures, minimizing localized overheating and carbonation within the tank. Residues are typically fluid asphalt remnants, allowing for gentler cleaning methods like hot oil flushing that cause minimal equipment damage.

Direct-fire heating: Bitumen is heated directly by a burner inside the tank. This method heats quickly but creates localized high temperatures, easily carbonizing asphalt near the tank walls. This forms thick, hard carbonized deposits that are difficult to clean. Mechanical cleaning methods are often required to remove stubborn residues, and special care must be taken during cleaning to avoid damaging the tank walls.

Electric Heating: Utilizes heat generated by electric heating elements to warm the bitumen. This method offers precise temperature control, good heating uniformity, and produces relatively fewer residues. However, since heating elements are typically installed inside the tank, extreme caution is required during cleaning to avoid damaging them. Chemical cleaning or steam cleaning—methods causing minimal equipment damage—are generally recommended.

Understanding the structural design and heating methods of bitumen tanks enables operators to develop more targeted cleaning plans before commencing work. This facilitates the selection of appropriate cleaning tools and agents, enhances cleaning efficiency, and minimizes potential damage to the equipment.

Depending on the type and thickness of residues inside the bitumen tank, as well as the heating method and structural characteristics of the equipment, different cleaning methods can be selected. The four primary methods commonly used are hot oil flushing, mechanical cleaning, chemical cleaning, and steam cleaning.

The core principle of hot oil flushing involves circulating heated thermal oil within the asphalt tank. The high temperature softens and dissolves asphalt residue adhering to tank walls and coil surfaces, which is then expelled from the tank along with the thermal oil, achieving cleaning.

Applicable Conditions: Suitable for thin residues and highly fluid asphalt residues, particularly compatible with thermal oil-heated asphalt tanks.

Procedure: Drain residual material from the tank, inspect the thermal oil system, heat to 180-220°C (adjust based on asphalt type and residue), operate the circulation pump for 2-4 hours (adjustable for enhanced efficiency), then discharge and process the dissolved residue.

Advantages: Simple operation, safe without damaging the tank, utilizes existing systems, reduces costs and improves efficiency.

Mechanical cleaning employs scrapers, wire brushes, rotating tools, or other equipment—manually or mechanically driven—to physically scrape and grind stubborn residues within bitumen tanks for thorough cleaning.

Applicable Scenarios: Suitable for tanks with hardened carbon deposits resistant to mild methods like thermal oil flushing, such as tanks heated by direct flame for extended periods without timely cleaning.

Safety Precautions: Ensure the bitumen tank is shut down and its internal temperature drops below 40°C before cleaning. Personnel must wear full PPE including heat-resistant gloves and dust masks. Maintain adequate ventilation inside the tank using vents or axial fans. Assign dedicated personnel to monitor outside the tank. Prohibit the use of spark-producing tools to prevent poisoning and explosion risks.

Chemical cleaning employs specialized asphalt cleaners that react with tank residues to dissolve, emulsify, or loosen them for removal. Common asphalt cleaners fall into two categories: solvent-based and eco-friendly.

Cleaner Types: Solvent-based cleaners primarily use organic solvents like kerosene or diesel, offering strong dissolving power and rapid cleaning but exhibiting high volatility and toxicity. Eco-friendly cleaners utilize biodegradable materials with low toxicity and weak corrosiveness, though they clean slowly and carry higher costs.

Safe Operating Procedures: Select cleaner and conduct small-scale testing; drain asphalt from tank and close valves; dilute per instructions (if required), then spray or pour; soak for 4-8 hours (adjust based on residue); flush residue with high-pressure water or tools; rinse multiple times with clean water to remove residual cleaner.

Advantages and Disadvantages Analysis: Chemical cleaning offers high efficiency, excels at cleaning complex structures, and reduces labor. However, some solvent-based cleaners are flammable and toxic, requiring strict environmental control. Improper selection or excessive concentration may corrode equipment.

The steam cleaning method utilizes high-pressure steam’s high temperature and impact force to soften and strip asphalt tank residues for cleaning.

Applicable Scenarios: Suitable for moderate residue thickness without large amounts of hard carbonized deposits. Effective for cleaning tank inner walls, coils, etc., and ideal for scenarios requiring no chemical residue.

Equipment and Operational Key Points: Requires equipment such as a high-pressure steam generator. During operation, maintain steam temperature at 160-180°C (320-356°F) and pressure at 0.8-1.2 MPa (11-16 psi). Excessive pressure may damage insulation layers, while insufficient pressure reduces cleaning effectiveness. Operators should move the handheld steam gun evenly. For stubborn areas, extend the spray duration, but avoid prolonged concentrated spraying on a single spot.

To ensure safe, orderly, and efficient asphalt tank cleaning, strictly follow these steps. Each phase is critical and must not be overlooked.

This foundational step directly impacts subsequent processes. First, shut down the bitumen tank heating system. Close power, fuel, and thermal oil circulation valves to prevent accidental equipment startup. Next, open the drain and oil discharge valves to empty the asphalt from the tank. Collect residual asphalt using an oil suction pump. Finally, wait until the tank temperature drops below 40°C (monitored via temperature sensors or thermometers) to avoid scalding risks and ensure cleaning safety.

Residue removal must be performed according to the characteristics of the tank residue and the established cleaning plan. For thermal oil flushing, activate the thermal oil circulation system to dissolve residues. For mechanical cleaning, personnel must wear protective gear and use tools to scrape, grind, and promptly remove debris. For chemical cleaning, complete filling, soaking, and rinsing as required. For steam cleaning, calibrate high-pressure equipment for spray removal. Assign dedicated personnel to monitor the process, dynamically adjusting cleaning methods and duration to ensure thorough removal.

Final flushing aims to remove residual debris, cleaning agents, and thermal oil from the tank to prepare for asphalt re-injection. After thermal oil or chemical cleaning, perform multiple flushes with clean thermal oil or water, utilizing the agitator for enhanced effectiveness. Following mechanical or steam cleaning, directly flush with high-pressure water. Flushing is considered complete when the drainage runs clear, free of residual debris and cleaning agent foam.

After flushing, promptly dry the bitumen tank to prevent moisture residue from causing asphalt degradation or equipment corrosion. Accelerate drying through natural ventilation (opening tank top vents) or using axial fans/hot air drying equipment for 8-12 hours (adjust based on temperature and humidity). After drying, personnel must inspect the tank walls, coils, pipe connections, and valves through access ports, focusing on corrosion, leaks, and component damage: Minor corrosion requires rust removal and anti-corrosion treatment; Leaks at connections or valves necessitate immediate seal replacement or repair; Damaged heating coils must be replaced by professionals. Ensure all equipment is fault-free before proceeding.

Adhering to procedures during system restart is critical for safe and stable operation. The following outlines key steps: valve inspection, asphalt injection, heating and temperature rise, monitoring, and trial production.

System restart must strictly follow procedures to guarantee safe and stable operation. First, close drain valves and inspection ports, confirming all valves are in proper condition. Slowly inject new asphalt while continuously monitoring temperature and liquid level to prevent overflow or excessive pressure. After injection, activate the heating system, raising temperature at a rate of 10-15°C per hour to avoid localized asphalt overheating and equipment damage. During heating, regularly inspect system parameters such as thermal oil temperature and pressure while simultaneously monitoring asphalt temperature and fluidity. Once asphalt reaches the appropriate temperature (150-180°C, model-dependent) with good fluidity, conduct trial production to observe asphalt delivery and mixing plant operation. Confirm all functions are normal before resuming full production.

Asphalt tank cleaning involves multiple hazards such as high temperatures, mechanical operations, and chemical agents. Therefore, strict safety measures must be implemented to ensure the personal safety of personnel and the integrity of equipment.

Before commencing cleaning, ensure the asphalt tank and its heating/conveying systems are completely shut down. Disconnect power, fuel, and thermal oil circulation. Hang a “Cleaning in Progress—Do Not Start” warning sign at equipment switches to prevent accidental operation. Cleaning may only commence once the internal temperature drops below 40°C. To accelerate cooling, open the tank top vents and spray a small amount of cooling water onto the tank walls (avoiding water ingress into the tank). High-temperature operations are strictly prohibited.

During cleaning operations, personnel must properly wear certified PPE:

When performing cleaning operations, personnel must wear appropriate personal protective equipment as follows: Heat-resistant gloves to prevent burns from high temperatures; – Dust masks for mechanical cleaning; – Respirators tailored to the type of cleaning agent used for chemical cleaning; Safety goggles to protect eyes; – Non-slip work boots to prevent falls; – Anti-static workwear when entering tanks for cleaning to avoid safety hazards caused by static electricity.

Long-term asphalt storage in tanks may leave residual combustible gases like benzene and toluene. High concentrations can explode upon contact with open flames. During cleaning, open tank ventilation ports and inspection hatches, or use axial fans for forced ventilation for over 30 minutes. After ventilation, verify combustible gas concentrations are below 10% of the lower explosive limit using detectors before proceeding. Additionally, prohibit open flames and smoking on-site; use explosion-proof tools. Obtain permits for hot work operations, clear flammable materials, and provide fire extinguishing equipment and supervisors.

Waste generated during cleaning—including asphalt residue, wastewater containing cleaning agents, and spent thermal oil—must be processed in compliance with environmental regulations. Asphalt residue shall be recycled by specialized companies or undergo harmless treatment. Wastewater must be settled, filtered, and neutralized to meet discharge standards before release. Spent thermal oil must be collected in sealed containers and recycled by qualified entities. Personnel handling these materials must wear appropriate protective gear to prevent chemical exposure.

Beyond regular cleaning, implementing daily scientific maintenance can effectively minimize residue buildup in asphalt tanks, reduce cleaning frequency, extend equipment lifespan, and lower operational costs.

Asphalt heating temperatures must be precisely controlled according to equipment specifications and operational requirements. Excessively high temperatures accelerate oxidation and carbonation, leading to carbon residue buildup and volatilization losses. Conversely, excessively low temperatures reduce flowability, increasing residue accumulation and complicating cleaning. For standard road petroleum asphalt, heating temperatures should be maintained between 150-180°C, with flexible adjustments based on penetration and softening point indicators. Regularly calibrate temperature sensors during operation to ensure accurate control.

Premium asphalt exhibits superior thermal stability and aging resistance, minimizing oxidation and carbonation during prolonged storage and heating, thereby producing fewer residues.

When selecting asphalt, prioritize nationally certified brands with established reputations. Then choose the appropriate grade based on climate and project requirements. In high-temperature regions, use asphalt with low penetration and high softening point to enhance thermal stability and reduce residue. During procurement and storage, inspect the cleanliness of transport tanks before unloading. Seal the inlet of storage tanks during storage to prevent contamination by impurities.

Periodic maintenance of key bitumen tank components reduces failures and cleaning frequency. Inspect insulation layers quarterly, promptly repairing any damage or detachment to prevent heat loss. Conduct comprehensive heating coil inspections every six months, performing pressure tests for leaks. Wipe off minor surface carbonization with a soft cloth dipped in cleaner. Calibrate temperature sensors monthly. Inspect valves and pipelines monthly for operational flexibility and interface sealing integrity. Promptly repair or replace faulty components to prevent asphalt residue degradation.

Compared to extensive cleaning after prolonged residue buildup, periodic light cleaning more effectively controls residue levels while reducing cleaning difficulty and costs. It is recommended to perform this monthly when the asphalt in the tank is nearly depleted and the temperature has dropped to 80–100°C. Inject a small amount of heat transfer oil or cleaning solvent, then start the mixing device at low speed for 10–15 minutes. Use the mixture to flush the tank walls and coils. After completion, drain the mixture and dispose of it properly. This method is simple to operate, causes no damage to equipment, effectively delays residue accumulation, reduces the frequency of mechanical or chemical deep cleaning, and significantly lowers maintenance costs.

The bitumen tank is the core equipment of an asphalt mixing plant, and its cleaning and maintenance directly impact production efficiency, product quality, and equipment lifespan. Regular, scientific cleaning prevents reduced heating efficiency, asphalt contamination, and equipment failures caused by residue buildup. Adopting appropriate cleaning methods, standardized operation, and proper safety precautions are key to efficient and safe cleaning.

Concurrently, routine maintenance is pivotal for reducing cleaning expenses. Implementing controlled heating, selecting premium asphalt, conducting regular equipment inspections, and performing mild periodic cleaning can minimize residue buildup within the tank, thereby decreasing cleaning frequency. It is recommended that asphalt mixing plants establish comprehensive maintenance protocols, enhance personnel training, and standardize operational procedures. For complex cleaning tasks or equipment malfunctions, promptly seek support from professional teams to ensure efficient bitumen storage tank operation.

In summary, only by integrating scientific cleaning with routine maintenance can the full performance of bitumen tanks be realized. This ensures the long-term stable operation of asphalt mixing plants, providing high-quality asphalt mixtures for road construction projects. Ultimately, this approach achieves dual improvements in economic efficiency and engineering quality.