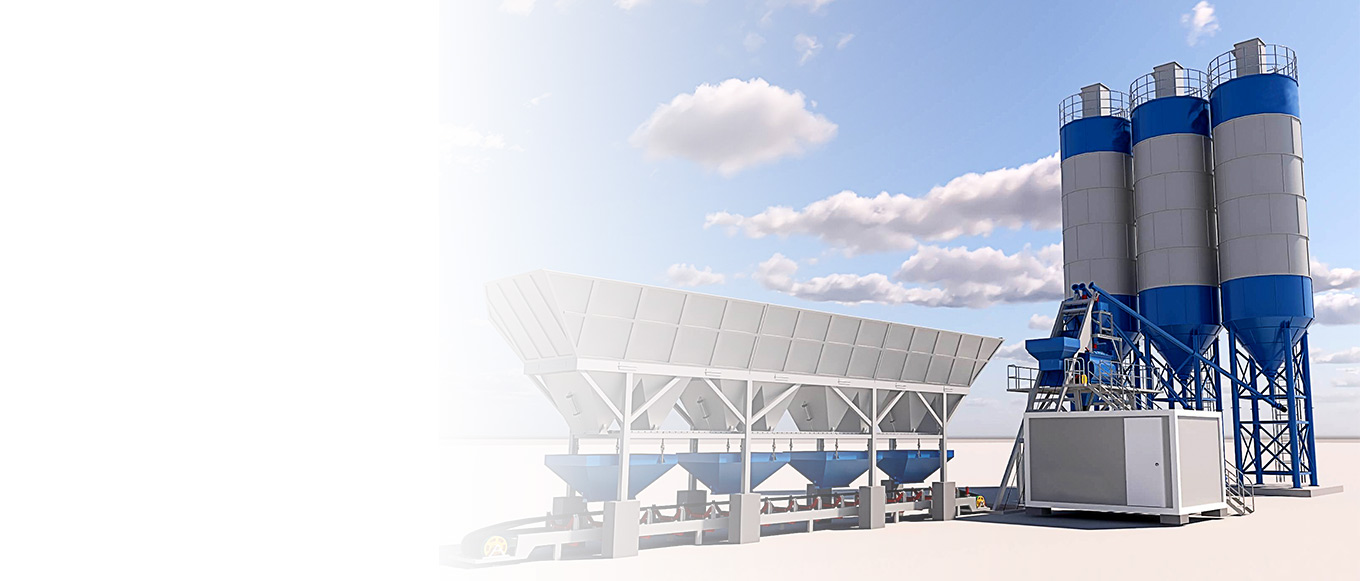

Introduction to Asphalt Mixing Plants

Asphalt mixing plants serve as core facilities in modern road construction, converting aggregates, asphalt, and other raw materials into various grades of asphalt mixtures. These mixtures provide essential materials for highways, parking lots, and various paving projects. Beyond their basic production functions, asphalt mixing plants offer multiple advantages in terms of efficiency enhancement, quality assurance, environmental performance, economic benefits, and application flexibility.

Improve the Production Efficiency of Construction

In the fast-paced modern road construction industry, improving construction efficiency is of utmost importance. As a critical piece of equipment in the construction process, asphalt mixing plants provide strong support for project progress through optimized production processes and intelligent design.

High-Speed Production Capacity

Traditional manual mixing methods are inefficient and lack stability, whereas asphalt mixing plants utilize automated production lines to achieve high-efficiency production capacity. Compared to manual mixing, they significantly reduce the production cycle of asphalt mixtures and quickly produce large quantities of qualified materials. This high-speed production not only saves construction time but also ensures projects proceed as scheduled, easily addressing the challenges of tight deadlines.

Convenient Operating Experience

Modern asphalt mixing plants are equipped with intelligent control systems, offering simple and efficient operation. Only a small number of specialized personnel are required to monitor and manage the entire process from raw material input to finished product output, significantly reducing labor costs. The simplified operation process reduces the likelihood of human error, allowing construction personnel to focus more on on-site construction tasks and further improve overall work efficiency.

Enhance the Quality of the Asphalt Mixture

The quality of the asphalt mix directly determines the service life and performance of road engineering projects. Asphalt mixing plants provide comprehensive quality assurance for high-quality mix production through multi-dimensional, precise control.

Precise Batching System

- Precise raw material measurement: The asphalt mixing plant is equipped with an advanced batching system that can precisely measure various raw materials such as coarse aggregate, fine aggregate, filler, and asphalt. By strictly controlling the quantity of each material it ensures that the asphalt mixture fully meets the design gradation requirements. Precise aggregate gradation and asphalt quantity are key to mixture performance, effectively avoiding performance instability issues caused by batching errors.

- Stable quality control: A stable batching process ensures consistent quality for each batch of asphalt mixture. Regardless of production scale, precise batching maintains mixture performance within a stable range, minimizing quality issues caused by batch variations and providing a reliable material foundation for road construction.

Efficient Mixing Process

The mixing equipment within the asphalt mixing plant achieves thorough and uniform mixing of all raw materials, ensuring that aggregate surfaces are uniformly coated with asphalt to form a stable structure. Optimal mixing enhances the bond strength between aggregate and asphalt, thereby improving the overall performance of the mixture. When preparing asphalt mixtures that meet specifications, uniform mixing is a critical step in ensuring their performance, and the efficient mixing equipment in asphalt mixing plants fully meets this requirement. Additionally, efficient mixing helps improve the stability of the mixture during storage and transportation, reducing segregation and ensuring that the mixture meets construction requirements and quality standards upon arrival at the construction site.

Strict Temperature Control

- Ensuring optimal construction temperature: The construction temperature of the asphalt mixture significantly affects its performance. The asphalt mixing plant can precisely control the heating temperature of asphalt, the drying temperature of aggregates, and the discharge temperature of the mixture, maintaining them within the optimal construction temperature range. Appropriate temperatures ensure that asphalt has good flowability, enabling better adhesion with aggregates while improving the compaction of the mixture. For special mixtures such as nano-silica modified asphalt, appropriate temperature conditions are crucial for fully leveraging their performance, and asphalt mixing plants can effectively control this core condition.

- Preventing material aging: Strict temperature control also prevents asphalt aging caused by excessive temperatures, thereby avoiding damage to mixture performance. Proper temperature management extends the service life of asphalt and ensures the long-term stability of asphalt mixture performance.

Advanced Quality Inspection Methods

- Real-time monitoring and feedback: Asphalt mixing plants are typically equipped with comprehensive quality inspection equipment to conduct real-time testing of raw materials, mixed materials during production, and finished products. By continuously monitoring performance indicators such as asphalt penetration, softening point, Marshall stability, and flow value, production parameters can be adjusted in a timely manner to ensure product quality.

- Comprehensive performance assessment: Using advanced testing methods, comprehensive performance assessments can be conducted on the high-temperature stability, low-temperature crack resistance, and water stability of asphalt mixtures. This enables the early identification of potential quality issues and the implementation of targeted improvement measures to further enhance mixture quality.

Professional Technical and Management Team

- Extensive experience and technical support: The asphalt mixing plant is staffed by professional technical personnel and managers who possess extensive experience and expertise in asphalt mixture production. They can optimize production processes according to different engineering requirements, resolve various technical challenges during production, and provide robust technical support to enhance asphalt mixture quality.

- Continuous Quality Improvement: The professional team continuously monitors the latest industry technologies and trends, improving production processes and management methods. By introducing new technologies and concepts, they continuously enhance the quality of asphalt mixtures to meet the increasingly stringent quality requirements of road engineering projects.

Excellent Environmental Performance

Asphalt mixing plants play a critical role in the production of road construction materials, with significant environmental advantages achieved through multiple technical measures to minimize environmental impact.

Application of Pollution Control Systems

- Function of baghouse dust collectors: Baghouse dust collectors are commonly used high-efficiency dust collection equipment in asphalt mixing plants. During asphalt production, large amounts of dust are generated. If directly emitted into the atmosphere, this not only degrades air quality, affects the living environment and health of surrounding residents, but may also reduce visibility and impact traffic safety. Baghouse dust collectors utilize filter media to capture dust particles on the surface of filter bags, with purified gas then discharged into the atmosphere via a fan. They have high filtration efficiency, effectively removing smaller dust particles, with strong capture capability for fine dust, ensuring that emitted gases meet strict environmental standards and significantly reducing dust pollution of the atmospheric environment. For example, some asphalt mixing plants using baghouse dust collectors can reduce dust emission concentrations to several dozen milligrams per cubic meter, a significant decrease compared to those without such equipment.

- Synergistic effects with other dust collectors: In addition to baghouse dust collectors, there are other types of dust collection equipment, such as cyclone dust collectors. Cyclone dust collectors utilize the centrifugal force generated by rotating airflow to separate dust particles from the airstream. They have a simple structure, lower costs, and are effective at separating larger dust particles. In practical applications at asphalt mixing plants, cyclone dust collectors are often used as primary dust collection equipment to preliminarily treat dust-laden gases, reducing dust concentrations before sending the gases to baghouse dust collectors or other fine dust collection equipment for further treatment. This synergistic approach involving multiple dust collectors enables more efficient removal of dust generated during asphalt production, achieving optimal environmental benefits. By reasonably configuring different types of dust collectors, asphalt mixing plants can optimize their dust collection systems based on their production processes and dust characteristics, minimizing the environmental impact of dust emissions.

Support for the Reuse of Recycled Asphalt Pavement (RAP)

- Resource recycling: Supporting the reuse of recycled asphalt pavement (RAP) involves reusing old asphalt pavement materials. In traditional road construction, old asphalt pavement materials are often discarded, not only occupying large amounts of land resources but also causing resource waste. By processing and reusing RAP through asphalt mixing plants, these waste materials can be converted into usable road construction materials. For example, after pre-processing recycled old asphalt pavement milling materials through crushing and screening, they are mixed with new aggregates, asphalt, and other materials in specific proportions to produce a recycled asphalt mixture for road paving. This reduces the need for new aggregate mining, lowers natural resource consumption, achieves resource recycling, and aligns with sustainable development principles.

- Reducing carbon emissions: From a carbon emissions perspective, using RAP offers significant environmental benefits. The extraction and processing of new aggregates consume large amounts of energy, such as fuel consumption during mining equipment operation and transportation, which generate substantial greenhouse gas emissions. By utilizing RAP, the need for new aggregate extraction is reduced, thereby lowering energy consumption and carbon emissions. Studies have shown that using a certain proportion of RAP in asphalt pavement construction can reduce the percentage of greenhouse gas emissions, such as carbon dioxide. Additionally, since RAP contains a certain amount of old asphalt, the demand for new asphalt during the recycling process is also reduced. Asphalt production is one of the primary sources of energy consumption and carbon emissions, so using RAP indirectly reduces carbon emissions during the asphalt production process, contributing positively to mitigating global climate change.

Modern Burner Technology Reduces Emissions

- Efficient combustion reduces pollutant generation: Modern burner technology employs advanced design and control concepts to achieve more efficient combustion processes. For example, some burners optimize their structure to ensure thorough mixing of fuel and air, enabling complete combustion of fuel within the combustion chamber and reducing the generation of byproducts from incomplete combustion. Incomplete combustion produces pollutants such as carbon monoxide and hydrocarbons, which not only pollute the atmospheric environment but also reduce energy utilization efficiency. Modern burners can effectively reduce emissions of these pollutants by improving combustion efficiency. Additionally, precise combustion control technology can adjust fuel and air supply in real-time according to production needs, keeping the combustion process in optimal condition and further reducing pollutant generation.

- Reducing nitrogen oxide emissions: Nitrogen oxides (NOx) are a major pollutant generated during the combustion process in asphalt mixing plants, posing a serious threat to the atmospheric environment and human health. Modern burner technology employs low-nitrogen combustion techniques, such as staged combustion and flue gas recirculation, to effectively reduce NOx emissions. Staged combustion divides the combustion process into multiple stages, controlling oxygen supply in each stage to alternate between oxygen-deficient and oxygen-rich combustion conditions, thereby reducing NOx formation. Flue gas recirculation reintroduces a portion of the post-combustion flue gas back into the burner, lowering the oxygen concentration and flame temperature in the combustion zone to suppress NOx formation. Through the application of these technologies, modern burners can reduce NOx emissions to extremely low levels, meeting increasingly stringent environmental standards and minimizing pollution to the atmospheric environment.

Other Environmental Benefits

- Reducing asphalt smoke emissions: Asphalt heating and mixing processes generate asphalt smoke, which contains various harmful substances such as polycyclic aromatic hydrocarbons (PAHs) like benzo[a]pyrene, posing potential risks to human health. Asphalt mixing plants can effectively reduce asphalt fume emissions by adopting closed asphalt storage and transportation systems and installing efficient asphalt fume collection and treatment devices on mixing equipment. For example, some advanced asphalt mixing plants use activated carbon adsorption technology to treat collected asphalt fumes, removing harmful substances to ensure emissions comply with environmental standards, thereby protecting the surrounding environment and worker health.

- Reducing noise pollution: The production equipment at asphalt mixing plants generates noise during operation, which may disrupt the lives of nearby residents. To reduce noise pollution, modern asphalt mixing plants have implemented a series of measures in equipment selection and layout. Low-noise production equipment is selected, such as applying advanced noise-reduction technology to key equipment like mixers and fans to minimize noise generated during operation. Additionally, equipment layout is planned reasonably, with high-noise equipment positioned away from residential areas, and soundproofing and vibration-reduction measures are implemented, such as installing soundproof enclosures and vibration-reduction pads, to minimize noise propagation. Through these measures, asphalt mixing plants can effectively reduce noise impact on the surrounding environment, creating a quieter living and working environment.

Lucrative Economic Benefits in the Long Run

Asphalt mixing plants provide long-term stable economic returns for various stakeholders, including investors, road construction companies, and landowners, making them a highly valuable investment opportunity.

For Investors

Investing in asphalt mixing plants is a reasonable asset allocation strategy and an important means of seizing market opportunities and achieving wealth appreciation.

- Sustained and stable market demand: Infrastructure construction is the foundation of modern societal development, and asphalt mixing plants are the core equipment for producing asphalt concrete. As urbanization continues to advance and infrastructure construction (such as roads, bridges, and airports) accelerates, the demand for asphalt concrete remains sustained and stable, providing a reliable market demand guarantee for asphalt mixing plants.

- High investment return rate: Asphalt mixing plants offer a high investment return rate. As they are essential for infrastructure construction, with stable market value and strong demand, investors can achieve substantial returns. This is particularly evident in regions with faster economic growth or during periods of significant infrastructure investment.

- Independent supply chain: Owning an asphalt mixing plant means establishing an independent supply chain, no longer solely reliant on external raw material suppliers. Investors can directly procure raw materials, reducing dependence on external suppliers and ensuring supply chain stability.

- Independent raw material procurement: Investors in asphalt mixing plants can independently select raw material suppliers and procure materials based on actual conditions. By collaborating with multiple suppliers or procuring materials independently, investors can secure better prices and quality assurance, thereby reducing raw material procurement costs.

- Control over raw material quality: Owning an asphalt mixing plant means having control over the quality and origin of raw materials. Investors can select high-quality raw material suppliers and establish long-term stable partnerships to ensure raw material quality and stability, thereby enhancing the production quality of asphalt concrete.

- Flexibly respond to market changes: Investors who own asphalt mixing plants can respond more flexibly to market changes and demand fluctuations. In the event of rising raw material prices or supply shortages, investors can promptly adjust their procurement strategies, seek alternative raw materials, or adjust production plans to ensure smooth production.

- Reduce supply risks: By independently procuring raw materials and establishing a stable supply chain, investors can reduce raw material supply risks. No longer solely reliant on external suppliers, they can better control supply chain stability and reduce risks associated with supply chain disruptions or raw material quality issues.

For Road Construction Companies

In a highly competitive market, road construction companies are constantly seeking ways to enhance their competitiveness, and investing in an asphalt mixing plant is seen as an important strategic move.

- Cost reduction and efficiency improvement, increasing profit margins: Asphalt concrete is an indispensable raw material in road construction. By owning an asphalt mixing plant, companies can produce asphalt concrete internally, reducing the costs previously incurred from purchasing from external suppliers. Additionally, by optimizing production and quality control, costs can be effectively reduced, and profit margins improved.

- Flexibly managing the supply chain and accelerating project progress: By owning their own asphalt mixing plants, road construction companies can better control the raw material supply chain. Whether it comes to raw material procurement or production scheduling, companies can flexibly allocate resources, respond more quickly to market demands, accelerate project progress, shorten project cycles, and thereby increase the number of projects and revenue.

- Ensure construction quality and establish a brand image: High-quality raw materials are one of the key prerequisites for ensuring construction quality. By owning their own asphalt mixing plants, road construction companies can manage materials and production processes to ensure the production of high-quality asphalt that meets standards. By improving construction quality and road durability, companies can establish a good brand image and enhance their market competitiveness.

- Save resources and achieve sustainable development: Producing asphalt concrete independently not only reduces costs but also helps conserve resources. By optimizing production and adopting advanced hot-mix equipment, energy consumption and waste are reduced, achieving efficient resource utilization. This initiative aligns with sustainable development principles and societal expectations of corporate responsibility, enhancing the company’s positive social image.

For Landowners

For landowners, investing in an asphalt mixing plant is an effective way to fully leverage land potential and achieve stable returns.

- Fully utilize idle land: If landowners have idle land, investing in an asphalt mixing plant is an ideal choice. Asphalt mixing plants require spacious sites, effectively utilizing idle land to turn it into a profitable asset and maximize its value.

- Stable rental income: By leasing land to asphalt mixing plant operators, landowners can secure stable rental income. Asphalt mixing plants play a critical role in infrastructure construction, with long-term leases providing landowners with stable and predictable rental income.

- Enhancing land value: By investing in an asphalt mixing plant, landowners can increase the economic and market value of their land. The presence of an asphalt mixing plant enhances the land’s appeal, making it a more promising investment opportunity and thereby boosting its market value.

- Promote regional economic development: The construction and operation of asphalt mixing plants drive economic development in surrounding areas. Investing in asphalt mixing plants attracts more investment, talent, and related industries, fostering regional economic growth and generating indirect benefits for landowners.

Flexibility for a Wide Range of Applications

Asphalt mixing plants are designed to accommodate diverse construction environments and project requirements, making them highly attractive in the road construction industry. It can handle challenges from urban streets to suburban highways, demonstrating exceptional adaptability and flexibility.

Wide Range of Application Scenarios

The design of asphalt mixing plants accommodates various construction conditions and environments. Whether it is narrow urban roads or wide national highways and expressways, asphalt mixing plants can quickly adapt and efficiently complete tasks. Their modular design allows for rapid assembly and disassembly of equipment, significantly improving on-site adaptability.

Flexible Configuration Options

Depending on project scale and specific requirements, asphalt mixing plants offer multiple configuration options. From small mobile mixing plants to large fixed-type mixing plants, each model delivers optimal performance and maximum efficiency. Customers can select the most suitable model based on project needs, ensuring the highest return on investment.

Adaptation to Diverse Technical Requirements

As construction technologies evolve, asphalt mixing plants continue to innovate to meet increasingly complex technical demands. They can process various types of asphalt mixtures, including hot-mixed asphalt, cold-mixed asphalt, and recycled asphalt, making them essential equipment in modern road construction. Additionally, advanced control systems ensure precise mixture ratios, meeting project quality standards.

Conclusion

Asphalt mixing plants are not only production facilities but also the core engines driving efficiency, quality, sustainability, and profitability. By enhancing construction speed, ensuring mixture durability, minimizing environmental impact, generating economic returns, and adapting to diverse needs, these facilities play a crucial role in building infrastructure that connects communities and drives development. For investors, contractors, and landowners alike, the advantages of asphalt mixing plants make them a highly valuable long-term investment in the future development of the construction industry.