In the production and operation of asphalt plants, filters play an indispensable role. Their maintenance is a critical factor affecting production efficiency, environmental compliance, and equipment safety. Prioritizing filter maintenance not only ensures the stable operation of asphalt plants but also represents a vital measure for enterprises to fulfill environmental responsibilities and reduce operational costs.

Ensuring Production Efficiency: Smooth filter operation guarantees unobstructed exhaust pathways in asphalt plants. This prevents issues like increased system resistance and insufficient airflow caused by clogged filter media, thereby maintaining continuous production processes and avoiding production interruptions or efficiency drops due to equipment malfunctions.

Compliance with Environmental Regulations: As environmental standards tighten, asphalt plants must strictly control pollutant emissions in exhaust gases. Filters effectively capture harmful substances like dust and particulates, ensuring emissions meet national and local environmental regulations and preventing penalties for non-compliance.

Extended Equipment Lifespan: Filters prevent dust and impurities from entering core equipment like blowers and heaters within asphalt plants. This reduces damage caused by dust abrasion and corrosion, lowers maintenance frequency and replacement costs, and significantly extends the overall service life of equipment.

Filtering Dust and Particulates to Ensure Compliant Exhaust Emissions: During production, especially when burning fuels like petroleum coke, asphalt plants generate substantial dust-laden exhaust gases. Filters utilize their structural design to trap harmful substances like dust and particulates from exhaust, ensuring treated emissions meet environmental standards and minimizing pollution to surrounding areas.

Protect internal components from dust damage: If dust-laden exhaust enters equipment directly, particles adhere to component surfaces, accelerating wear and aging. This compromises operational precision and performance. Filters effectively block dust ingress, maintaining optimal operating conditions for internal components.

Reduced Production Efficiency: Neglected filters become clogged, causing decreased airflow and increased pressure within the system. This reduces efficiency in heating, ventilation, and other processes at the asphalt plant, prolonging production cycles and impacting overall progress, resulting in lost production capacity.

Increased Equipment Wear: Neglected filters fail to effectively block dust. When large amounts of dust enter the equipment, it accelerates wear on moving parts like fan bearings and motors. This increases equipment failure rates, not only raising repair costs but also potentially causing greater economic losses due to equipment downtime.

Environmental Pollution and Regulatory Penalties: If filters develop issues like torn filter bags or poor seals due to inadequate maintenance, unfiltered dust-laden exhaust gases will be directly released into the atmosphere, causing environmental pollution. Should emission levels exceed regulatory standards, the company will face penalties from environmental authorities, including fines and production suspensions for rectification. This severely damages the company’s reputation and disrupts normal operations.

The core functions of asphalt plant filters manifest in two aspects: dust removal and environmental protection. On one hand, they physically intercept and separate solid impurities such as dust and particulate matter from exhaust gases, achieving gas purification. On the other hand, through efficient dust removal, they ensure exhaust emissions from asphalt plants comply with environmental standards. This supports enterprises in achieving green production, minimizes ecological damage, and fulfills social responsibilities.

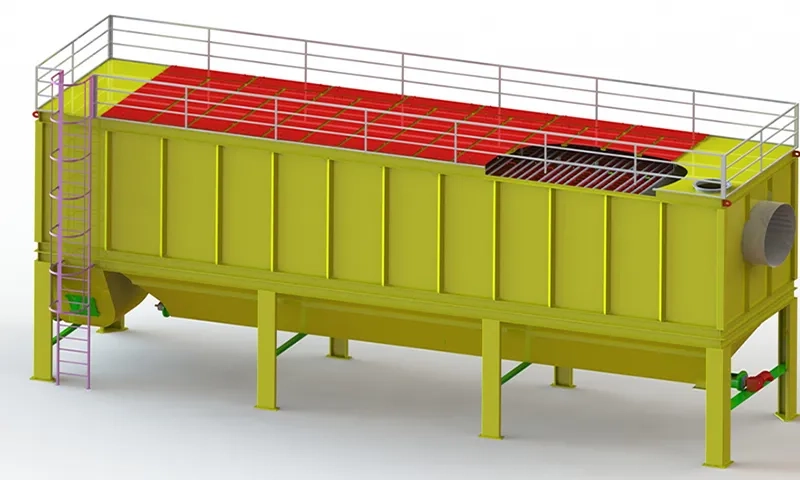

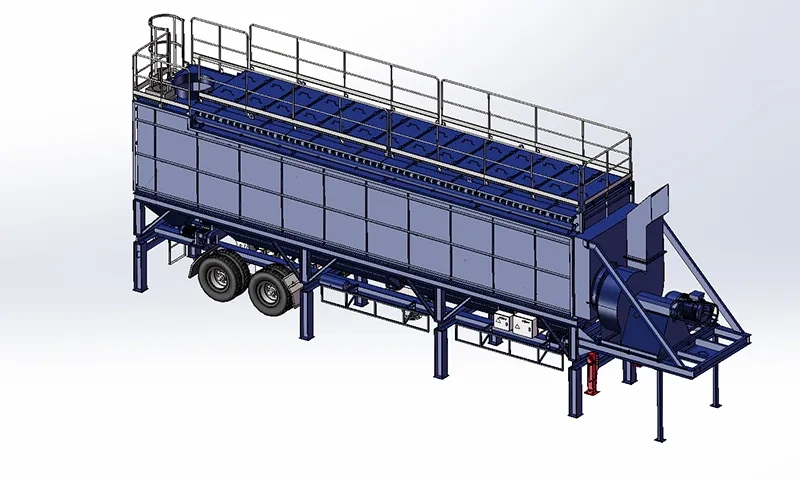

Baghouse Filter (Baghouse Dust Collector): Also known as an industrial bag filter, this is the most widely used filter type in asphalt plants. They utilize a series of filter bags with microscopic pores as the filtration medium. As dust-laden exhaust gas passes through the bags, dust and particulate matter are trapped on the bag surface, while purified gas passes through the bags and is discharged. As the filtration process continues, dust accumulates on the bag surface. When a certain pressure differential is reached, the dust must be cleaned via a cleaning device or the filter bags replaced to maintain filtration efficiency. Within the asphalt plant production process, bag filters are typically installed at multiple stages—such as heating and cooling—to ensure effective treatment of exhaust gases generated throughout each production phase.

Cartridge Filter: The cartridge filter employs a pleated cartridge as its core filtration element, providing a large filtration area within a compact space. Their operating principle is similar to bag filters, trapping dust and particulates through the pores of the filter media. Cartridge filters offer high filtration efficiency, low resistance, and easy replacement. They are suitable for areas within asphalt plants with relatively low dust concentrations and limited space, such as dust removal during raw material conveyance.

Cyclone Separator: Cyclone separators utilize centrifugal force to separate dust from gas. Dust-laden exhaust enters the cyclone inlet at high velocity, where it undergoes rotational motion within the housing. Under centrifugal force, dust and particulates are flung toward the housing walls, subsequently settling into the hopper for collection. Purified gas is discharged through the top exhaust port. Cyclone separators feature simple construction, low cost, and easy maintenance. However, their filtration efficiency for fine particles is relatively low. In asphalt plants, they are often used as pre-filtration equipment in conjunction with bag filters or cartridge filters. This setup first removes larger dust particles from the exhaust gas, reducing the filtration burden on subsequent filters.

Filter Media (Fabric Bags, Cartridges): Filter media are the core components enabling filtration functionality, directly determining filtration efficiency and service life. Fabric bag media are typically made from high-temperature and wear-resistant fibers such as polyester or glass fiber, capable of withstanding the high-temperature environment in asphalt plant production processes. Cartridge media are often paper or synthetic fiber materials that undergo special treatment to achieve high filtration precision and stability. Different filter media suit varying operating conditions, requiring selection based on factors like exhaust gas temperature, humidity, and dust properties at the asphalt plant.

Dust Removal System (Reverse Air Cleaning System, Pulse Jet Cleaning System): The dust removal system promptly clears accumulated dust from the filter media surface, restoring filtration performance and ensuring stable filter operation. The reverse air cleaning system introduces clean air in the opposite direction to the filter media, causing vibration that shakes off surface dust. The pulse jet cleaning system employs compressed air for instantaneous bursts, generating intense airflow impacts to dislodge accumulated dust from the filter media surface. In bag filters at asphalt plants, pulse-jet systems are more widely adopted due to their superior cleaning effectiveness and high efficiency, effectively preventing filter media blockage caused by excessive dust accumulation.

Dust Collection System (Hoppers, Dust Discharge Ports): The dust collection system gathers dust and particulates dislodged by the cleaning mechanism and expels them from the filter. The hopper, located at the bottom of the filter, features a funnel shape to facilitate dust accumulation and descent. The waste dust discharge port, positioned at the hopper’s base, is equipped with control devices such as valves to periodically discharge collected dust for centralized processing. Within asphalt plants, collected waste dust must be properly disposed of in accordance with environmental regulations to prevent secondary pollution.

Sudden Increase in Dust Emissions: If significantly higher dust concentrations are observed at the asphalt plant’s exhaust outlet—such as noticeable black or gray smoke—this may indicate filter media damage, poor sealing, or incomplete cleaning. This allows unfiltered dust-laden exhaust to escape directly, necessitating immediate filter inspection and maintenance.

Decreased System Airflow or Pressure: During asphalt plant operations, increased fan operating current, noticeable reduction in outlet airflow, or sustained system pressure drop may indicate filter media clogging causing increased system resistance. Perform filter cleaning. If airflow and pressure remain abnormal after cleaning, inspect filter media for damage and replace if necessary.

Abnormal Noise from Exhaust Equipment: If exhaust equipment like fans produces unusual noises during operation—such as sharp friction sounds or vibration noises—this may result from loose internal components, damaged filter media rubbing against equipment parts, or excessive fan load due to clogged filter media. Immediately shut down the equipment for inspection to identify the cause of abnormal noise and perform corresponding maintenance.

Visual Detection of Dust Accumulation, Filter Bag Damage, or Seal Wear: During routine inspections, if excessive dust accumulation is observed in the filter hopper, visible holes or tears appear on filter bag surfaces, or filter seals show signs of aging, cracking, or wear, maintenance must be performed promptly. Excessive dust accumulation impairs the dust collection system’s normal operation, while damaged filter bags and worn seals reduce filtration efficiency, leading to pollutant emissions exceeding standards.

Peak Season (Recommended Inspection Frequency: Every 1-2 Weeks): During asphalt plant production peaks, such as road construction surges, equipment operates continuously with high exhaust emissions. Filters face heavy workloads, accelerating filter media wear and dust accumulation rates. To ensure stable filter operation, conduct comprehensive inspections every 1-2 weeks. This includes assessing filter media integrity, cleaning device functionality, and overall dust collection system performance to promptly identify and address potential issues.

Pre-startup Inspection After Extended Downtime: Following prolonged shutdowns (e.g., holidays, maintenance), perform thorough filter inspection and maintenance before resuming production. Prolonged shutdowns may cause issues such as moisture-induced clumping of accumulated dust inside the filter, filter media aging, seal deformation, and the accumulation of debris within the equipment. Pre-startup checks should focus on the integrity of the filter media, the unobstructed operation of the cleaning device and dust collection system, and the normal functioning of electrical circuits. The filter should only be put into operation after confirming that all performance indicators meet the startup requirements.

Wear necessary personal protective equipment (PPE) such as dust masks and gloves: During filter maintenance, personnel will be exposed to significant amounts of dust and particulate matter. Some work environments may also involve risks like high temperatures and hazardous gases. Therefore, appropriate PPE must be worn, such as dust masks to prevent respiratory harm from inhaled dust; wear abrasion-resistant, heat-resistant gloves to protect hands from mechanical injury and burns; depending on conditions, safety goggles and protective clothing may also be required to ensure comprehensive worker safety.

Ensure equipment is shut down, power is disconnected, and Lockout/Tagout procedures are implemented: Before commencing maintenance, all equipment associated with the filter—such as fans and cleaning devices—must be stopped and power sources disconnected to prevent accidental startup during maintenance, which could cause accidents. Simultaneously, strictly enforce the Lockout/Tagout procedure by securing equipment power switches, valves, etc., and affixing “Under Maintenance – Do Not Operate” warning signs. This clearly informs other personnel that the equipment is in maintenance mode and prohibits unauthorized operation.

Cleaning Tools: Vacuum cleaner, brushes, high-pressure air gun: The vacuum cleaner is used to remove loose dust from the interior of the filter and the surface of the filter media. Especially when replacing filter media, it can be used to thoroughly clean accumulated dust from the hopper and the interior of the equipment, preventing dust from becoming airborne and causing secondary contamination. Brushes are suitable for cleaning stubborn accumulated dust on the surface of the filter media. Choose soft brushes that are unlikely to damage the filter media. The high-pressure air gun cleans nozzles, pipes, and other components of the dust removal system to ensure unobstructed flow and enhance cleaning efficiency.

Spare Parts: New filter bags or cartridges, sealing gaskets, etc.: During maintenance, if filter bags or cartridges are found damaged, aged, or unusable, they must be replaced promptly. Therefore, spare parts matching the filter model should be prepared in advance. Sealing gaskets are critical components for ensuring filter sealing performance. If gaskets are aged or worn, they must also be replaced immediately to prevent exhaust gas leakage and maintain filtration efficiency.

At the filter maintenance site, establish dedicated maintenance zones that are cleaned and isolated. These areas must remain dry and dust-free, preventing accumulation of debris. Lay protective mats or plastic sheeting around the zones to contain dust and waste filter materials during maintenance, avoiding environmental contamination. Discarded filter media, gaskets, and other waste materials must be promptly collected and placed in designated containers for disposal in accordance with environmental regulations to prevent secondary contamination.

Lightly tap or knock bag filters to remove loose dust: For bag filters, gently tap or knock the surface to dislodge loose dust. During operation, gently tap the upper and middle sections of the filter bag with your hand or a specialized tapping tool, applying moderate force to prevent bag damage from excessive pressure. This vibration causes loose dust to fall into the hopper, where it is subsequently removed by the dust collection system.

Cleaning Filter Media Surfaces with Industrial Vacuum Cleaners: For fine dust on the surfaces of cartridge filters or bag filter bags, an industrial vacuum cleaner can be used for cleaning. Position the vacuum nozzle close to the filter media surface and move it slowly, utilizing the suction power to draw dust into the dust collection bag. During cleaning, take care to avoid scratching the filter media surface with the nozzle, which could impair filtration performance.

Pulse-jet cleaning system: Inspect nozzle and pulse valve functionality: As a common cleaning mechanism for bag filters, the pulse-jet system requires pre-inspection of nozzles and pulse valves before mechanical cleaning. Check nozzles for blockages or deformation; if blocked, clear debris using a high-pressure air gun or specialized tools. Verify that pulse valves operate smoothly and maintain proper sealing. Address any air leaks or delayed responses promptly through repair or replacement. After confirming normal operation of nozzles and valves, activate the pulse jet system. Execute cleaning cycles according to preset pulse duration and intervals to dislodge accumulated dust from the filter bag surfaces.

Reverse Air Cleaning System: Ensure unobstructed operation of the fan and reverse airflow system: This system uses reverse airflow generated by the fan to clean the filter media. Before cleaning, inspect the fan’s operational status to ensure it runs normally with sufficient air volume. Inspect the reverse airflow system piping for blockages or leaks. If blockages occur, promptly clear accumulated dust and debris from the pipes. If leaks are detected, repair the affected sections to maintain proper reverse airflow pressure and volume. After activating the reverse airflow system, adjust the fan speed and reverse airflow duration to ensure the reverse airflow effectively dislodges dust from the filter media surface.

High-temperature filter media must be protected from wet cleaning and physical abrasion: Certain filter media in asphalt plants, such as glass fiber filter bags in baghouse filters, must withstand elevated temperatures. Wet cleaning is strictly prohibited for such high-temperature media, as moisture degrades performance and may damage the material. Additionally, avoid using sharp tools or vigorously rubbing the surface during cleaning to prevent physical abrasion that compromises filtration efficiency and service life.

Avoid Scratching Abrasion-Resistant Coated Media with Sharp Tools: Some filter media feature abrasion-resistant coatings to enhance durability and longevity. When cleaning such media, avoid using sharp brushes or tools that could scrape the surface, as this may cause the wear-resistant coating to peel off. This would reduce the media’s abrasion resistance and shorten its service life.

To ensure the filter’s efficiency and stable operation, establish a reasonable schedule for regular dust removal. It is recommended to perform a minor cleaning of the filter daily. Minor cleaning involves activating the cleaning mechanism to remove a small amount of accumulated dust from the filter media surface, preventing dust buildup. Conduct a thorough cleaning weekly or biweekly. During thorough cleaning, comprehensively inspect and clean the filter media, cleaning mechanism, dust collection system, etc., to completely remove stubborn dust deposits from the filter media surface and debris inside the equipment, ensuring all performance indicators of the filter remain in good condition.

Check for Holes, Tears, or Broken Stitching: Filter bags are the core filtration components of bag filters, and their integrity directly impacts filtration efficiency. During inspection, carefully examine the surface of the filter bags for visible holes or tear marks. Simultaneously, check the stitching areas for broken or detached threads. If holes or tears are found, determine whether repair or replacement is necessary based on the extent of damage. If stitching is broken, promptly re-sew the seams to prevent dust leakage.

Test for reduced air permeability: Filter bag air permeability significantly impacts filtration efficiency and system resistance. Test the pressure differential across the filter bag to determine if permeability has decreased. If the pressure differential significantly increases under the same airflow conditions, it indicates reduced permeability, likely caused by clogged or aged filter media. Clean the filter bag at this point. If permeability does not recover after cleaning, replace the filter bag.

Inspect pleats for blockage or rupture: The pleated structure of filter cartridges increases filtration area but is prone to dust accumulation causing blockage or pleat rupture due to external forces. During inspection, examine each pleat individually for dust buildup in the crevices or signs of pleat rupture/deformation. If blockages are found, clean them using a high-pressure air gun or vacuum cleaner. If pleats are torn, this will reduce the filtration area and efficiency, requiring immediate replacement of the filter cartridge.

Check the seal integrity between the filter cartridge and the equipment: Poor sealing between the cartridge and the equipment allows unfiltered dust-laden exhaust gas to leak directly through gaps, reducing filtration efficiency. During inspection, apply soapy water to the connection between the filter cartridge and the equipment. Start the equipment and observe for bubbles. Bubbles indicate a seal leak. Check if the sealing gasket is aged or damaged, or if the filter cartridge is properly installed. Replace damaged sealing gaskets promptly and adjust the filter cartridge’s installation position to ensure a good seal.

Ensure the frame is free from corrosion and deformation: The filter frame supports the filter media and secures equipment components. Corrosion or deformation compromises the filter’s overall structural stability and the precision of media installation. During inspection, examine the frame surface for rust or corrosion spots and check the frame structure for bending or deformation. If minor corrosion is detected, perform rust removal and anti-corrosion treatment. Replace the frame immediately if severe corrosion or noticeable deformation is present to prevent media detachment or equipment failure.

Verify seal strips are tightly sealed and free from aging: Seal strips secure all filter connections to prevent exhaust gas leakage. Inspect for cracks, aging, or hardening on the strip surface. Ensure the strip adheres tightly to the connection without gaps. If seals show signs of aging or damage, replace them promptly. If seals do not fit tightly, adjust the tightness of the connection points or apply sealant to the seal surface to ensure a secure seal.

The dust collection system is critical for centralized dust treatment in the filter. Its unobstructed operation directly impacts the overall efficiency of the filter. Focus on inspecting the following two aspects:

Cleaning accumulated dust from the hopper and ductwork: The hopper of an asphalt plant filter is the primary dust accumulation area. If not cleaned regularly, accumulated dust can absorb moisture and form clumps. This not only reduces hopper capacity but may also block the hopper outlet, preventing dust discharge or even causing it to flow back into the filtration area, resulting in secondary contamination. During cleaning, first close the hopper discharge valve and open the access door. Use an industrial vacuum cleaner or specialized scraper to thoroughly remove accumulated dust from the hopper. For pipelines connecting the dust hopper to waste dust treatment equipment, inspect the inner walls for accumulated dust. If the pipeline has a small diameter or multiple bends, use a high-pressure air gun to inject compressed air from one end, blowing the dust into the hopper for centralized removal. Ensure no residual dust remains on the pipeline walls.

Verify ash discharge port functionality: As the final exit point for dust leaving the filter, a blocked discharge port or faulty valve can cripple the entire dust collection system. During inspection: – Visually check for visible dust buildup at the discharge port. – Manually operate the discharge valve to ensure smooth opening/closing and proper sealing. If foreign objects are found blocking the outlet, remove them promptly. If the valve exhibits sticking, air leaks, or other issues, disassemble it for maintenance. Replace worn valve cores or seals to ensure the outlet opens and closes properly, allowing dust to discharge smoothly.

Filter elements (filter bags/cartridges) are the core consumables of the filter. When damaged or degraded, they must be replaced promptly to maintain filtration efficiency. The specific steps are as follows:

Not all filter media require replacement only after complete failure. Prioritize replacement under the following three conditions:

When filter bags or cartridges are severely damaged beyond repair: If filter bags exhibit large tears, holes exceeding 5mm in diameter, or filter cartridges show multiple pleat fractures or structural damage to the media, replacement is required even if repairs are attempted. Similarly, immediate replacement is necessary if materials degrade due to high temperatures or chemical corrosion to prevent contaminant leakage through damaged areas.

When pressure differential abnormally increases persistently: Under normal operation, the pressure differential between the filter inlet and outlet should remain within a specific range (typically 500-1500 Pa). If, after multiple cleaning cycles, the pressure differential remains persistently above the set threshold (e.g., exceeding 2000 Pa), and factors like duct blockage or fan failure have been ruled out, it indicates severe internal clogging of the filter media. Pores are filled with dust, resulting in significantly reduced air permeability. Continued use will cause insufficient system airflow and increased energy consumption, necessitating replacement of the filter media.

When filter media exhibits severe surface dust accumulation that is difficult to thoroughly clean: If the filter surface forms a hard “crust” due to highly viscous or moisture-laden dust, rendering it impossible to remove deposits even with high-pressure air guns or reverse air cleaning, the filter efficiency will continue to decline. In such cases, replace the filter media to prevent accelerated aging caused by prolonged dust adhesion.

Strictly adhere to safety protocols when replacing filter media to prevent dust contamination and equipment damage:

Properly remove old filter media to minimize dust dispersion: Before removal, close the filter inlet valve to ensure no airflow within the equipment. Wear dust masks and gloves. After opening the access door, first use an industrial vacuum cleaner to remove loose dust from the surface of the old filter media. Then loosen the fasteners securing the media to the frame (e.g., clips, bolts). When removing filter bags from baghouse filters, grasp the top and pull downward slowly to prevent dust release from bag movement. For cartridge filters, remove vertically along the cartridge axis to prevent dust release from pleats. Immediately place removed filter media into sealed bags to contain dust.

Inspect sealing and fastening after installing new filter media: Before installing new filter media, verify compatibility with the filter model and inspect surfaces for damage or deformation. When installing bag filters, securely connect the top clamp or lifting ring to the frame, ensuring vertical suspension without tilting. For cartridge filters, ensure end gaskets fully seal against equipment interfaces and tighten mounting bolts to eliminate gaps. After installation, gently pull the filter media by hand to verify secure fixation. Simultaneously inspect for gaps at the interface between the filter media and equipment. Apply sealant to sealing areas as needed to enhance sealing integrity.

Test New Filter Media Performance to Ensure Stable Operation: After installation, close the maintenance door first. Slowly open the inlet valve and fan, observing the pressure differential at the filter inlet and outlet to ensure it remains within the normal range. After 10-15 minutes of operation, inspect the exhaust outlet for dust leakage. Use a dust detector near the outlet to measure dust concentration. If the concentration meets environmental standards, the new filter media is functioning normally, and the filter can resume regular operation.

Used filter media from asphalt plant filters accumulates significant dust and contaminants on its surface, qualifying it as hazardous waste. It must be disposed of according to environmental regulations:

Separate Collection: Sort replaced filter media by material type (e.g., fabric bags, filter cartridges) and place them in dedicated leak-proof, corrosion-resistant containers. Affix a “HAZARDOUS WASTE” label to the exterior, specifying the filter media type, replacement date, and generating unit.

Entrust Disposal to Professional Agencies: Strictly prohibit discarding waste filter media indiscriminately or mixing it with household waste. Engage a third-party agency certified for hazardous waste disposal, sign a disposal agreement, and arrange for professional personnel to collect and transport the materials. Ensure waste filter media undergoes compliant treatment via incineration, landfill, or other authorized methods to prevent secondary environmental pollution. Retain disposal records and transfer manifests for inspection by environmental authorities.

The stable operation of the filter relies on the coordinated functioning of supporting systems. While maintaining the filter itself, simultaneous maintenance of the compressed air system, dust collection system, and differential pressure monitoring equipment is required:

The compressed air system serves as the power source for the pulse-jet cleaning system, and its operational status directly impacts cleaning effectiveness:

Inspect the air tank, valves, and pressure of the pulse-jet cleaning system for normal operation: – Periodically open the drain valve at the bottom of the air tank to remove accumulated water and oil residue, preventing moisture ingress into the blowpipe that could dampen filter media. – Check the air tank pressure gauge and safety valve to ensure the gauge reading remains within the normal operating pressure range (typically 0.5-0.7 MPa) and that the safety valve activates properly to relieve pressure, avoiding overpressure operation of the air tank. Verify pulse valve wiring connections are secure and inspect valve bodies for air leaks. Manually trigger pulse valves to observe whether the valve core operates smoothly and whether the blow pressure is stable. If pulse valve malfunctions are detected, repair or replace them promptly.

Promptly remove moisture and oil residue from compressed air pipelines after filtration: Even after drying and filtration, compressed air may retain trace moisture and oil. Long-term accumulation can adhere to pipeline walls, causing blockages or corrosion. Periodically remove filter cartridges from pipelines and blow out impurities with compressed air. Replace cartridges if clogged or deteriorated. For pipe bends and joints, use specialized cleaning tools to remove oil residue and deposits from inner walls, ensuring unobstructed compressed air flow and preventing contaminants from entering the pulse-jet system.

Beyond routine cleaning of hoppers and ductwork, maintain other dust collection system components:

Check the operation of ash discharge valves: Ash discharge valves (e.g., star discharge valves, gate valves) are critical components controlling dust discharge. Regularly inspect whether the valve motor operates with normal sound and whether the lubricating oil in the gearbox is sufficient and free from deterioration. If abnormal motor noise or cloudy lubricating oil is detected, promptly repair the motor and replace the lubricating oil. Inspect valve blades or gate plates for wear. If gaps appear in the sealing surfaces, adjust valve clearances or replace seals to prevent dust leakage at valve points.

Cleaning Waste Dust Conveying Equipment: If the dust collection system includes waste dust conveyors such as screw conveyors or scraper conveyors, regularly inspect for internal dust accumulation or blockages. Check conveyor belts or scrapers for misalignment or wear, and ensure rollers or bearings are adequately lubricated. During cleaning, first shut down the equipment and disconnect power. Open the maintenance door and use scrapers or high-pressure air guns to remove accumulated dust. Adjust the tension of the conveyor belt and replace worn components to ensure waste dust is smoothly transported to the designated treatment area.

Differential pressure monitoring equipment continuously tracks the pressure difference across the filter inlet and outlet, serving as a critical indicator for assessing filter media condition and determining cleaning timing. Key maintenance tasks include:

Calibrate differential pressure sensors to ensure accurate readings: Calibrate sensors every 3 months by connecting them to a standard pressure gauge and comparing readings. If deviation exceeds ±5%, calibrate per the sensor manual. Inspect sensor wiring for secure connections and check probes for dust blockage. If dust accumulates on the probe surface, gently wipe it with a soft cloth dampened with alcohol to ensure accurate pressure signal acquisition.

Adjust cleaning frequency based on differential pressure changes: Monitor differential pressure patterns across operating conditions using differential pressure monitoring equipment. If the rate of pressure increase accelerates, indicating faster dust accumulation on filter media, shorten cleaning intervals appropriately (e.g., from 1 hour to 40 minutes). If the pressure differential remains persistently low, it may indicate filter media damage or insufficient airflow. Troubleshoot the cause first before adjusting the cleaning frequency to prevent excessive cleaning that could wear out the filter media.

Establishing comprehensive maintenance records and schedules is central to achieving “preventive maintenance” for filters, effectively reducing failure rates:

Document equipment operating status and maintenance activities: After each maintenance session, meticulously record the maintenance date, personnel, and type (e.g., routine inspection, cleaning, filter media replacement). Simultaneously log critical filter parameters including inlet/outlet pressure differential, cleaning frequency, filter media service duration, fault symptoms, and corrective actions. For example: “On [Date], dust removal performed on Bag Filter #1. Pre-cleaning pressure differential: 1800Pa. Post-cleaning pressure differential: 800Pa. Pulse valves functioning normally. Dust hopper cleared.” Such records provide a clear overview of the filter’s operational status.

Facilitates tracking and troubleshooting historical issues: Maintenance records serve as the filter’s “health records.” When a malfunction occurs, reviewing historical data allows tracing the timing, resolution methods, and outcomes of similar issues, enabling rapid identification of root causes. For example, if a filter repeatedly experiences abnormal pressure differential spikes, records may reveal that hopper cleaning was neglected before each failure. This indicates hopper blockage as the root cause, enabling optimization of cleaning cycles to prevent recurrence.

Develop a preventive maintenance plan tailored to the asphalt plant’s production load and filter operating patterns to avoid “over-maintenance” or “under-maintenance”:

Establish periodic inspection and maintenance schedules based on usage intensity: Divide maintenance cycles according to the asphalt plant’s production seasons. During peak seasons (e.g., summer road construction) with high production loads and extended filter operation times, implement a “weekly inspection + monthly maintenance” plan: Conduct routine weekly checks including filter media appearance, cleaning system pressure, and exhaust dust concentration; Monthly deep maintenance includes disassembling and cleaning the pulse-jet ducts, calibrating the differential pressure sensor, and inspecting frame corrosion. During off-peak seasons with low production loads, adjust to a “monthly inspection + quarterly maintenance” schedule to reduce maintenance costs while ensuring reliable equipment operation.

Optimize maintenance timing using predictive failure technologies (e.g., differential pressure monitoring): Establish a predictive failure model by combining real-time data from differential pressure monitoring equipment with the filter media’s lifespan curve. For example, when the differential pressure sensor detects a sustained increase in pressure differential exceeding the normal range, the system automatically issues an early warning. This alerts maintenance personnel to prepare replacement filter media and schedule the replacement time, preventing production interruptions caused by sudden filter failure. Simultaneously, by analyzing differential pressure changes under different operating conditions, optimize cleaning frequency and maintenance cycles to achieve “on-demand maintenance,” thereby improving maintenance efficiency.

During operation, asphalt plant filters are prone to issues such as filter bag clogging, damage, and poor sealing. Targeted measures should be implemented:

Filter bag clogging is the most common fault, primarily manifested by increased system pressure differential and reduced airflow. Address this through root cause analysis and remedial actions:

Insufficient cleaning frequency: If cleaning intervals are too long, accumulated dust on the filter bag surface is not removed promptly, gradually forming a dense dust layer that blocks the filter bag pores;

Filter Clogging: Excessively high exhaust gas temperatures (exceeding the filter media’s tolerance) or the presence of viscous substances (e.g., asphalt volatiles) in the exhaust gas cause dust particles to adhere and fuse on the filter bag surface due to heat, resulting in “clogged bags”;

High Dust Moisture Content: If raw material humidity is high or the production environment is damp, dust readily absorbs moisture and clumps together, adhering to the filter bag surface and becoming difficult to clean.

For insufficient cleaning frequency, shorten the cleaning interval, increase the number of pulse jet bursts, or adjust the burst pressure to enhance cleaning effectiveness;

If filter bag caking occurs, first inspect the exhaust gas temperature to ensure it remains within the filter media’s tolerance range (e.g., glass fiber media withstands temperatures up to 260°C). Simultaneously clean caked filter bags; severely caked bags requiring removal should be replaced.

For high dust moisture content, install a drying device at the filter inlet to reduce exhaust gas humidity. Concurrently increase hopper cleaning frequency to prevent dust accumulation and clumping.

Damaged filter bags cause direct dust leakage and environmental contamination. Promptly investigate and address the cause:

Excessive air velocity: Inlet air velocity exceeds design specifications (typically ≤1.5 m/s). High-speed airflow carries dust particles that impact and wear the filter bags.

Filter media aging: Prolonged exposure to high temperatures, chemical corrosion, or repeated cleaning impacts causes the material to age, become brittle, and crack;

Uneven stress distribution: Improper vertical installation or frame deformation causes friction between the filter bag and frame during operation, leading to localized stress failure.

For excessive air velocity, adjust fan speed or increase the filter’s inlet cross-sectional area to reduce inlet velocity;

For filter media aging, replace filter bags and verify media selection meets process requirements; replace with high-temperature resistant or wear-resistant media if necessary;

For uneven stress distribution, reposition filter bags, repair deformed frames, and ensure vertical suspension without friction damage.

Inadequate sealing allows unfiltered exhaust gas to escape, reducing filtration efficiency. Focus on inspecting and repairing sealing areas:

Common causes: Aging or deformed sealing strips; dust or debris on sealing surfaces during installation causing poor contact; loose bolts at connections (e.g., filter access doors, inlet valves, ash discharge valves) creating gaps; loose connections between filter media and frames resulting in gaps.

Remedial Actions:

If sealing strips are aged, replace them with new ones (e.g., silicone or fluororubber strips). Clean dust and debris from sealing surfaces beforehand to ensure flatness.

If bolts are loose, inspect each connection point and tighten to specified torque using a torque wrench. Apply anti-loosening adhesive to bolts if necessary.

If the filter media is loosely attached to the frame, re-secure the media and adjust its position to ensure tight contact with the frame. Install sealing gaskets at connection points if necessary.

Beyond the above two faults, asphalt plant filters may also experience issues such as “insufficient air flow” or “fire risk”:

Insufficient Air Flow: Causes may include fan malfunction (e.g., reduced motor power, dust accumulation on impeller blades), duct blockage, or severe filter bag clogging. Address by first inspecting fan operation, cleaning impeller dust, and repairing fan faults; then clear duct and filter bag dust to ensure unobstructed airflow.

Fire Risk: Asphalt plant exhaust contains flammable substances (e.g., petroleum coke volatiles). Excessive dust accumulation on filter bags may spontaneously combust when exposed to high temperatures. Install spark detectors and fire suppression systems at the filter inlet. Regularly clean dust from filter bags and hoppers to prevent spontaneous combustion. Additionally, use flame-retardant filter media to reduce fire hazards.

Maintenance personnel’s professional skills directly impact filter maintenance quality. Systematic training is essential to enhance their capabilities:

Improve maintenance personnel’s professional skills: Asphalt plant filters vary widely (e.g., baghouse, cartridge types) with complex maintenance procedures spanning mechanical, electrical, and environmental disciplines. Training equips personnel to master filter media inspection, cleaning system calibration, and troubleshooting, preventing equipment damage from improper operation.

Strengthening Safety and Environmental Awareness: Maintenance involves risks like working at heights, dust exposure, and energized equipment. Since filter maintenance is closely tied to environmental compliance, training reinforces safety protocols (e.g., Lockout/Tagout procedures) and environmental awareness, preventing accidents or penalties from non-compliance.

Training topics should align with practical maintenance needs, emphasizing practicality and relevance:

Filter Media Inspection and Replacement Techniques: Cover visual inspection methods for different media types (fabric bags, cartridges), damage assessment criteria, disassembly/installation procedures, and media selection knowledge (e.g., material selection based on temperature and dust properties). Hands-on field training ensures personnel master correct replacement workflows.

Cleaning System Setup and Calibration: Explain the operating principles of pulse-jet and reverse-air cleaning systems. Train personnel to adjust cleaning frequency, jet pressure, and duration based on pressure differentials. Cover troubleshooting cleaning valve malfunctions and cleaning jet lines to ensure efficient system operation.

Safety and Environmental Compliance: Training covers proper use of personal protective equipment (PPE), execution of lockout/tagout procedures, disposal requirements for hazardous waste (e.g., spent filter media), and environmental regulations (e.g., Comprehensive Emission Standards for Air Pollutants) governing filter emissions to ensure operations meet safety and environmental standards.

To maintain technical advancement amid evolving filtration technologies, continuously update maintenance personnel knowledge:

Monitor Trends in New Filter Media and Cleaning Technologies: Regularly gather industry intelligence to understand the performance characteristics and application scenarios of new filter media (e.g., PTFE-coated media, high-temperature ceramic media) and the operating principles of intelligent cleaning technologies

(e.g., AI-based adaptive cleaning systems). Compile this into technical materials distributed to maintenance teams to ensure timely awareness of emerging industry innovations.

Case sharing and experience summarization: Organize regular technical exchange meetings for maintenance personnel to share filter failure resolution cases (e.g., troubleshooting complex bag clogging, techniques for identifying poor sealing issues), summarizing successful approaches and common pitfalls. Simultaneously, collect operational challenges encountered by maintenance staff, collaboratively explore solutions, and integrate best practices into the knowledge base to develop standardized maintenance guidelines.

External Training and Collaboration: Partner with filter manufacturers and environmental technology institutions to organize external professional training for maintenance personnel, enabling them to learn advanced maintenance techniques and equipment management methods. Invite industry experts for on-site guidance, providing customized technical support tailored to the specific operating conditions of asphalt plant filters. This helps the maintenance team resolve technical challenges and enhances their overall professional capabilities.

Maintenance of asphalt plant filters should adhere to the principle of “prevention first, timely intervention.” Core points can be summarized as follows:

Regular cleaning and inspections are essential: Cleaning is fundamental to maintaining filter performance. Establish a schedule for daily light cleaning and weekly deep cleaning based on production load. Conduct periodic inspections (every 1-2 weeks during peak seasons; mandatory before restarting after shutdown) of critical components like filter media, seals, and cleaning systems to prevent dust accumulation, blockages, or component damage that could escalate failures.

Accurate Replacement Timing and Standardized Procedures: Filter media replacement should be determined by evaluating pressure differential changes, damage levels, and dust removal effectiveness to avoid premature replacement causing waste or delayed replacement impacting production. Strict dust-proofing protocols must be followed during replacement to ensure proper sealing of new media. Confirm operational stability through performance testing and dispose of used media according to environmental regulations.

Coordinate maintenance of supporting systems and monitoring equipment: Filter stability relies on the coordinated operation of compressed air systems, dust collection systems, and differential pressure monitoring devices. Synchronize maintenance of these supporting equipment—such as cleaning moisture and oil contamination from compressed air pipelines, inspecting ash discharge valve operation, and calibrating differential pressure sensors—to ensure efficient interlocking between all systems and the filter.

Consistent regular maintenance of asphalt plant filters delivers multifaceted benefits for enterprises:

Enhanced asphalt plant operational efficiency: Clean, unobstructed filters reduce system resistance, ensuring normal operation of equipment like blowers and heaters. This prevents production interruptions or capacity drops caused by filtration issues, lowers energy consumption (e.g., blower power consumption can decrease by 10%-15% when differential pressure is normal), and boosts overall production efficiency.

Ensure Environmental Compliance and Reduce Operating Costs: Regular maintenance effectively prevents dust leakage caused by damaged filter media or poor seals, ensuring exhaust emissions meet environmental regulations. This mitigates risks of penalties, production halts for rectification, and other sanctions. Simultaneously, timely maintenance extends the lifespan of filter media and equipment, reducing the frequency of spare part replacements and equipment repair costs, thereby lowering long-term operational expenses.

Safeguard production safety and personnel health: Standardized maintenance reduces filter fire risks (e.g., through dust removal and use of flame-retardant filter media), minimizes workshop contamination from dust leaks, protects frontline workers’ respiratory health, fosters a safe and clean production environment, and lowers accident rates.

To achieve long-term stable operation of asphalt plant filters, we propose these two core recommendations:

Develop a Scientific Maintenance Plan and Documentation System: Create a customized maintenance schedule based on the asphalt plant’s production cycle, filter model, and operating conditions. Clearly define timelines and operational standards for daily inspections, periodic dust removal, and deep maintenance. Simultaneously establish a comprehensive maintenance documentation system to meticulously record parameters, fault details, and corrective actions for each maintenance session. This forms a “health record” for the equipment, providing a basis for future maintenance optimization and troubleshooting.

Prioritize training to cultivate a professional maintenance team: Integrate filter maintenance training into the company’s regular training system. Enhance maintenance personnel’s technical skills and safety/environmental awareness through theoretical instruction, hands-on field practice, and case studies. Encourage the team to track industry advancements in new technologies and equipment, regularly updating their knowledge base. Build a professional maintenance team proficient in technology, skilled in operation, and capable of resolving complex issues, thereby ensuring a talent pool for stable filter operation.

In summary, asphalt plant filter maintenance is a systematic endeavor that must balance production efficiency, environmental compliance, and equipment safety. Only through scientific planning, standardized operations, and continuous technical advancement can the full potential of filters be realized, laying a solid foundation for the sustainable operation of asphalt plants.