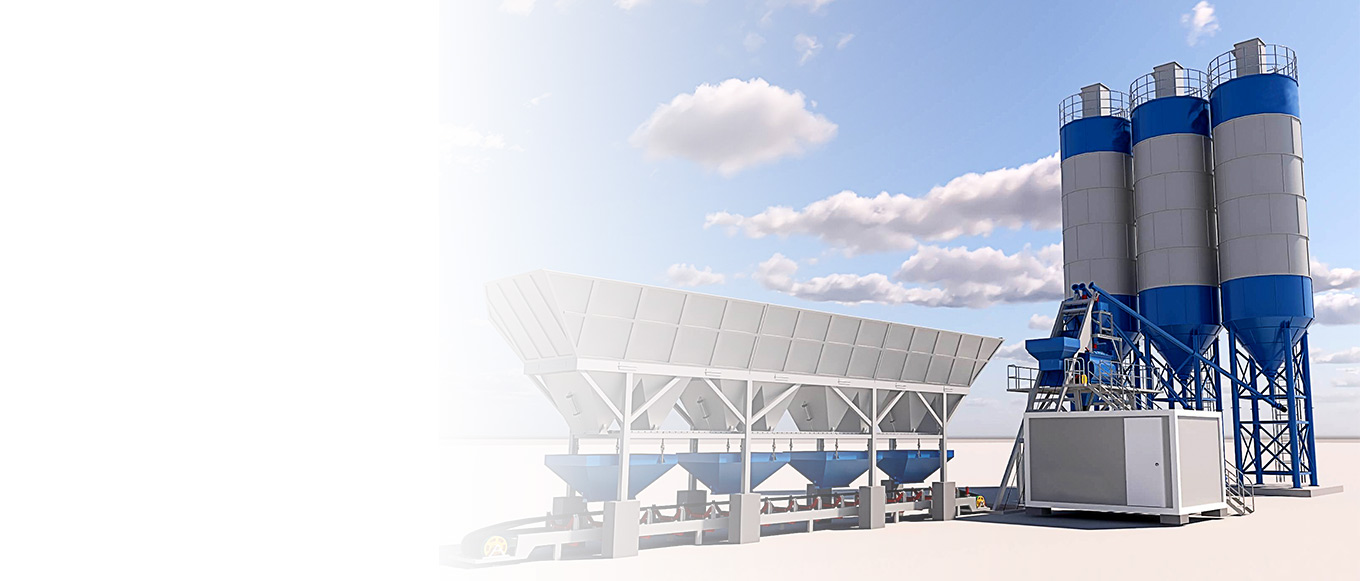

Brief Overview of Mobile Asphalt Plant

Mobile asphalt plant is a portable asphalt production facility designed specifically for road construction and related engineering projects. It integrates the core components of an asphalt mixing plant, including cold aggregate bins, dryers, drum mixers, and hot aggregate storage bins, into a compact, self-contained unit.

As the construction industry continues to evolve, project models have become increasingly flexible and diverse, leading to a growing demand for flexibility in asphalt production. The mobile asphalt mixing plant, with its unique design and functionality, has become an increasingly important solution in the construction industry, favoured by many construction companies as an asphalt production solution.

Main Advantages of Using a Mobile Asphalt Plant

Significant cost-effectiveness

Reduced transportation costs

No need for long-distance transportation of finished asphalt; production takes place directly at the construction site, significantly reducing fuel consumption and vehicle wear and tear.

For example, a small road project in a suburban area used a mobile asphalt mixing plant, resulting in a 30% reduction in transportation costs compared to purchasing from a fixed mixing plant 50 miles away.

Reduced Setup and Operational Costs

Installation is faster than fixed plants, shortening project preparation time. Infrastructure requirements are simple, with no need for complex permanent foundations.

Case Study: A construction company in a rural area set up a mobile asphalt mixing plant for a 6-month project, achieving a 40% cost reduction compared to renting a fixed plant of the same scale.

Outstanding Flexibility and Mobility

Adaptability to diverse construction sites

Capable of operating in remote or hard-to-reach areas, suitable for both urban and rural projects.

For example, in a mountain road widening project, a mobile asphalt mixing plant was successfully deployed, whereas a fixed plant could not access the area.

Easy transfer between multiple sites

Ideal for projects involving multi-region operations or phased construction.

Example: During a series of small-scale road repairs in different urban communities, the efficient relocation of the mobile asphalt mixing plant saved the construction company significant time.

Ensuring High-Quality Asphalt Production

Utilizing Advanced Mixing Technology

Precise control of aggregate and asphalt ratios ensures uniform mixing and consistent asphalt quality.

Technical details: Modern mobile mixing plants use computer-controlled systems, with aggregate and asphalt ratio accuracy controlled within ±0.5%.

Meeting strict quality standards

Capable of meeting industry standards and specific project quality requirements.

Asphalt produced by a mobile asphalt mixing plant for a large infrastructure project performed excellently in all quality inspections.

Environmental characteristics

Reducing carbon footprint

On-site asphalt production reduces transportation, thereby lowering related carbon emissions.

Data example: In a certain project, the mobile asphalt mixing plant reduced carbon dioxide emissions by 50tonnes per month compared to using the stationary asphalt mixing plant.

Recycling and emissions control functionality

Some mobile plants can recycle old asphalt materials, achieving resource reuse.

Equipped with efficient dust and pollutant control systems.

For example, in a project in an environmentally sensitive area, the mobile asphalt mixing plant recycled 20% of old asphalt, reducing waste and lowering environmental impact.

Easy Installation and Operation

Simple Installation Process

Installation time is shorter than for fixed mixing plants, typically completed within a week. Clear steps with no complex preliminary preparations required.

Easy to operate

Short training period for operators, with skills easily mastered. Intuitive control system for efficient operation.

A construction company reported that new operators could operate the mobile asphalt mixing plant proficiently after just a few days of training.

Enhancing Project Efficiency

On-site production available immediately

No need to wait for asphalt transportation; it can be used directly for construction, optimizing workflows and project schedules.

In a busy urban road construction project, on-site production from the mobile mixing plant enabled the paving team to work continuously, reducing the overall project timeline by 15%.

Rapid Response to Project Changes

Production scale can be adjusted as needed to flexibly address unforeseen circumstances during projects.

In a road repair project, when additional potholes requiring repair were discovered, the mobile asphalt mixing plant quickly increased production to meet the urgent demand.

Suitable for various project types

Suitable for projects of different scales

Multiple production capacity options are available to match various project scales.

For example, mobile asphalt mixing plants can be used for small-scale community road repairs requiring 20–50 tonnes of asphalt per day, as well as large-scale highway construction projects requiring 100–200 tonnes per day.

Suitable for various road construction scenarios

Whether it is new road construction, pavement renovation, or routine maintenance, the mobile asphalt mixing plant can play a role. It can flexibly address asphalt production needs in different construction scenarios, providing support for all stages of road construction.

What Types of Road Construction Projects Benefit the Most from a Mobile Asphalt Plant?

Small-scale road construction project

Project details

Location: A coastal town. The project objective is to connect a new residential area with the main road, with a road length of approximately 2 kilometers.

Application of mobile asphalt mixing plants

A 30tonne/hour tyre-mounted mobile asphalt mixing plant was selected, with the installation process completed in just 2 days. Approximately 50 tonnes of asphalt are produced daily based on construction progress, fully meeting project requirements.

Significant Benefits Achieved

Transportation costs were reduced by approximately 40%, eliminating expenses associated with transporting asphalt from a distant fixed plant. The project schedule was shortened by one week, as asphalt could be produced on-site without waiting for transportation. Road quality received positive feedback from local residents and regulatory authorities, with all testing indicators meeting standards.

Road Maintenance and Repair Project

Project Description

Maintenance work on a busy road in the city centre, spanning 3 kilometers, requiring repairs to multiple cracks and potholes. Due to high traffic volume, the project required minimizing disruption to traffic, with tight deadlines.

Role of the Mobile Asphalt Mixing Plant

A tracked mobile mixing plant was used, which can be set up in narrow spaces alongside the road and moved with the construction section. Asphalt is produced on-site and supplied promptly to the maintenance work area, avoiding the issue of asphalt cooling due to prolonged transportation time.

Positive Outcomes

The project was completed 3 days ahead of schedule, reducing traffic congestion time. Local transportation authorities reported that the impact on traffic from this maintenance project was the lowest among similar projects.

Large-Scale Infrastructure Projects

Project Overview

A three-year highway expansion project spanning 50 kilometers, requiring a large volume of asphalt for pavement laying.

Contributions of the Mobile Asphalt Mixing Plant

Two container-type mobile mixing plants were deployed, with a combined production capacity of 250 tonnes per hour, ensuring a continuous supply of asphalt.

Production plans were flexibly adjusted according to the project’s varying needs at different stages to accommodate changes in engineering volume.

Benefits to the Overall Project

Compared to using fixed mixing plants, approximately 15% of total costs were saved, primarily from transportation and site rental expenses.

The project was completed one month ahead of schedule without any downtime due to asphalt supply issues.

Common Types of Mobile Asphalt Plants

Equipped with tyres, it can be easily moved on roads and is suitable for short-distance transfers. It can be transported without heavy lifting equipment, simplifying the transportation process.

Example: A tyre-mounted mobile asphalt mixing plant was used in a 20-mile-long highway maintenance project, moving flexibly between different work sections and efficiently completing the asphalt production task.

Production Capacity and Suitable Projects

Production capacity typically ranges from 20 to 80 tonnes per hour.

Ideal for highway maintenance and small-scale road construction projects requiring movement through urban streets.

Data: In a small-scale road renovation project in a city, a 50-tonne-per-hour tyre-mounted mobile mixing plant perfectly met the construction requirements.

Track-mounted Mobile Asphalt Mixing Plant

Equipped with tracks, it performs exceptionally well on rugged terrain with strong stability. It ensures continuous asphalt production even in complex construction site environments.

Case Study: A tracked mobile asphalt mixing plant operated stably on the uneven terrain of a mining area, providing reliable asphalt supply for mining road construction.

Production Capacity and Application Scenarios

Production capacity typically ranges from 40 to 120 tonnes per hour.

Suitable for mining areas, remote regions, and mountainous road construction projects.

For example, in a mountainous road construction project, an 80-tonne-per-hour tracked mobile mixing plant became a critical piece of equipment for the project’s smooth progress.

Semi-Mobile Asphalt Mixing Plant

Requires partial disassembly for relocation but offers greater flexibility than stationary asphalt plants.Production capacity exceeds that of fully mobile asphalt plants, meeting the sustained demand of medium-scale projects. In a medium-scale road construction project in a newly developed area, a 120-tonne-per-hour semi-mobile asphalt mixing plant played a crucial role.

Suitable for medium-term projects with duration’s typically ranging from several months to about a year.

Can provide continuous supply for projects with stable asphalt demand.

Analysis: In a 9-month urban infrastructure construction project, the semi-mobile mixing plant was the optimal choice due to its moderate production capacity and mobility.

Container-type Mobile Asphalt Mixing Plant

Components are housed in standard containers, facilitating long-distance transport, particularly suitable for sea or rail transport. Modular design simplifies maintenance, allowing individual components to be inspected or replaced. In an international infrastructure project, the containerized mobile asphalt mixing plant was transported by sea, quickly installed, and put into operation.

Production capacity can reach 60-180tonnes per hour, which is Ideal for large-scale international infrastructure projects, meeting the demands of long-distance transportation and large-scale production.

Case Study: In the construction of a major highway abroad, a 150tonne per hour containerized mobile mixing plant operated efficiently, ensuring a steady supply of asphalt for the project.

Stationary and Mobile Asphalt Plants: What’s the Difference?

Stationary asphalt plant is more complex than the mobile asphalt plant. These plants require more permanent foundations and preparation, as the weight of the components can be much greater. Additionally, transportation costs are often higher due to stationan prep is required to operate a portable plant. It can be installed in a shorter timeframe, making it ideal for shifting locations and limited space. Most portable asphalt mixing plants are prewired, facilitating a faster installation time.

Overview of Stationary Asphalt Mixing Plants

Features

Larger in size and more complex in structure, requiring a large site for installation.

Typically installed permanently at a single location, requiring a permanent foundation.

Description: A large fixed asphalt mixing plant in an industrial zone, covering a vast area with a robust and complex foundation, featuring large-scale equipment and numerous components.

Advantages

High production capacity, suitable for large-scale, long-term projects.

May offer higher efficiency under specific conditions.

For example, in a large-scale highway construction project requiring a constant supply of asphalt, the fixed mixing plant met the project’s needs with its high production capacity.

Key Differences Between Mobile Asphalt Mixing Plants

Mobility-Related Differences

Compact size, easy to transport, and can be quickly set up and relocated.

Can adapt to temporary needs at different construction sites without requiring long-term site occupation.

Imagine this: a mobile asphalt mixing plant transported by truck can be installed and ready for production at a new site within a day.

Cost and Space-Related Differences

Lower setup and operational costs for temporary projects.

Small footprint with minimal site requirements.

Cost comparison data shows that mobile mixing plants offer significantly higher cost-effectiveness than fixed mixing plants for short-term projects.

Step-by-Step Guide to Setting Up a Mobile Asphalt Batch Mix Plant

Step 1: Assess Project Requirements

Before installing the mixing plant, analyse the project scope, expected output, asphalt and aggregate requirements, and production schedule. Select a mobile asphalt mixing plant with appropriate production capacity based on the project scale (typically ranging from 60 to 160 tonnes per hour).

Step 2: Site Selection

Select a location that is easily accessible, flat, and well-drained. Ensure that the location is close to aggregate sources, asphalt supply points, and the paving construction site. Sufficient space must be reserved to accommodate equipment components, material storage areas, truck access lanes, and safety zones.

Step 3: Foundation and Site Preparation

Although mobile equipment requires minimal foundation work, the ground must be levelled and a solid foundation prepared to ensure stability. Use compacted gravel or concrete pads as anchors.

Step 4: Equipment Module Installation

Most mobile asphalt mixing plants feature a modular design. First, position and align critical components, including: cold aggregate feed bins, drying and mixing drums, bag-house dust collectors, asphalt and fuel storage tanks, control rooms and automated control panels, and hot mix storage silos.

Use lifting equipment operated by trained personnel to ensure components are properly aligned and securely connected.

Step 5: Connect utility systems

Connect power lines, fuel supply (diesel, fuel oil, or coal), and compressed air systems. Ensure proper ventilation for burners and exhaust systems.

Step 6: Calibration and trial runs

Conduct dry and wet trial runs to verify: aggregate feeding accuracy, asphalt flow and temperature, drum speed, mixing quality and batch uniformity, and exhaust control system performance.

Resolve any deviations before initiating full-scale production.

Conclusion

Mobile asphalt mixing plants demonstrate significant advantages in terms of cost-effectiveness, flexibility, production quality, environmental friendliness, ease of operation, project efficiency, and applicability. These advantages directly translate into enhanced profitability and market competitiveness for construction companies, enabling them to complete asphalt production tasks more efficiently and economically across various construction projects.

In the future, mobile asphalt mixing plants are expected to achieve greater breakthroughs in production efficiency and environmental performance, such as more advanced energy-saving technologies and more efficient material recycling systems.

As the construction industry continues to demand greater flexibility and cost control, the demand for mobile asphalt mixing plants is projected to grow steadily. Whether for small rural road construction or large-scale international infrastructure projects, mobile asphalt mixing plants will increasingly be relied upon to meet asphalt production needs.

Mobile asphalt mixing plants undoubtedly provide construction companies with superior asphalt production solutions, serving as a crucial driving force for the development of the modern construction industry.