Asphalt Mixing Plant For Sale in Bangladesh

In recent years, Bangladesh has entered a “golden age” of infrastructure development. With population growth, accelerated urbanization, and deepening regional economic cooperation, the country’s demand for a high-quality road network has become increasingly urgent. From expressways connecting the capital Dhaka to major economic zones, to rural roads serving remote villages, and transportation hubs anchored by the Padma Bridge, large-scale road construction projects are emerging rapidly. Behind this boom, efficient and reliable asphalt mixing plants—as core equipment for road construction—are becoming critical factors determining project quality and progress, driving explosive growth in market demand.

Bangladesh’s Road Construction Market: Policy-Driven, Robust Demand

The Bangladesh government views infrastructure development as a core engine for economic growth, consistently increasing investment in roads, bridges, industrial parks, and related sectors in recent years. At the national level, the “Bangladesh Vision 2041” explicitly outlines plans to build a nationwide modern transportation network, including over 20 national-level expressway projects alone. The inauguration of the Padma Bridge served as a pivotal turning point, directly catalyzing road upgrading projects across six surrounding divisions with associated infrastructure investments reaching tens of billions of taka.

This policy impetus has not only activated government-led mega-projects but also attracted numerous private construction firms to compete in the market. Currently, Bangladesh hosts over 5,000 registered private construction contractors, with more than 300 possessing qualifications to undertake large-scale road projects. As these companies undertake projects like rural road paving and industrial park infrastructure, their demands for asphalt pavement quality have risen significantly. Simple gravel surfaces can no longer meet the needs of heavy-duty transportation and long-term durability. High-strength, water-resistant asphalt pavements have become the mainstream choice, further amplifying market demand for high-performance asphalt mixing plants.

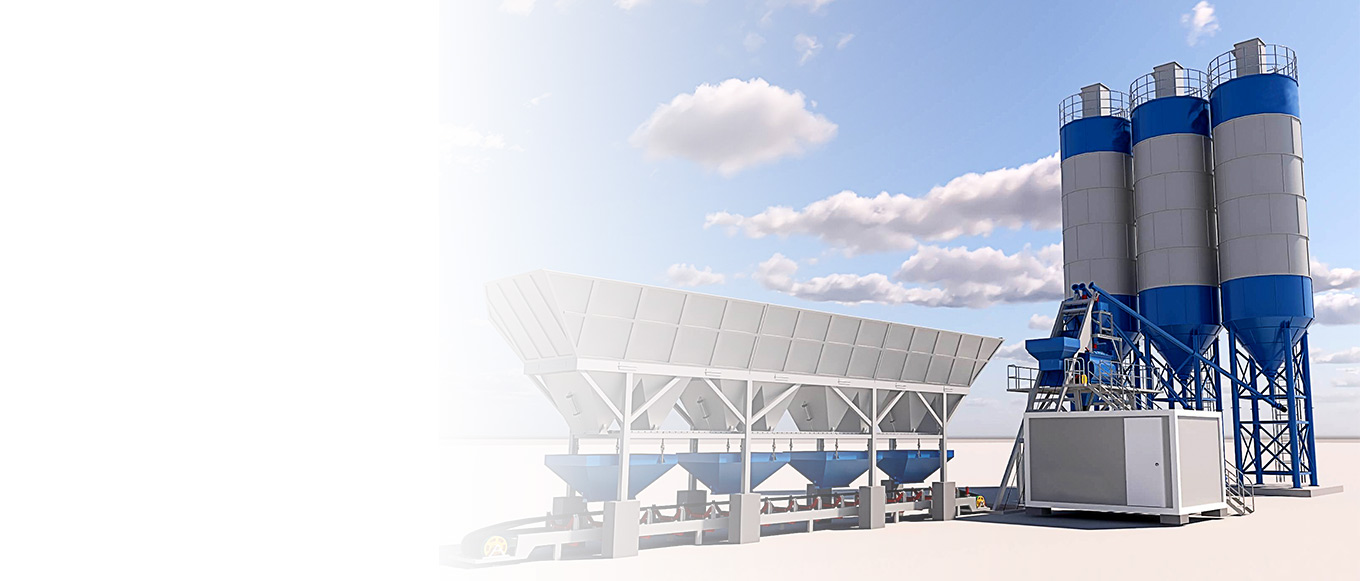

Mainstream Asphalt Mixing Plant Types in Bangladesh: Selecting the Right Type Based on Needs is Key

Considering the project characteristics, budget levels, and construction environments across different regions in Bangladesh, the mainstream asphalt mixing plants on the market are primarily categorized as follows. Each type of equipment has distinct application scenarios and advantages:

Batch Mix Asphalt Plant: The Preferred Choice for High-End Projects

Batch mix plants, renowned for their precise batching control and consistent mixing quality, serve as core equipment for high-end road projects in Bangladesh, including urban arterial roads and highways. Their operating principle involves batch-mixing aggregates, asphalt, and other raw materials according to preset ratios. Each batch achieves mixing precision within ±1%, effectively ensuring critical indicators like Marshall stability of the asphalt mixture, thereby extending road service life. Currently, batch plants in Bangladesh primarily operate at capacities ranging from 60 to 160 TPH (tons per hour). Major projects like the Dhaka Ring Road and Chittagong-Dhaka Expressway extensively utilize this equipment.

Continuous Drum Mix Asphalt Plant:

The Cost-Effective Choice

For budget-constrained projects like rural roads and county highways, continuous asphalt plants are favored for their lower initial investment and continuous production capability. These units achieve simultaneous aggregate drying and asphalt mixing through drum rotation, delivering high efficiency with daily outputs exceeding 1,000 tons per unit. Their relatively simple structure also results in lower maintenance costs. In concentrated rural road construction areas like the Rangpur and Rajshahi Divisions in northern Bangladesh, continuous plants hold over 60% market share, serving as the primary equipment driving rural transportation upgrades.

Mobile/Portable Asphalt Plant: Flexible Solution for Dispersed Projects

Many road projects in Bangladesh are scattered, particularly small-scale works in remote areas where transportation costs for traditional fixed plants are prohibitively high. Mobile asphalt plants address this challenge through rapid disassembly and crane-assisted transport. Featuring modular designs, these units can be transported by truck to any site after disassembly, with installation and commissioning taking only 3-5 days—ideal for contractors handling multiple dispersed small projects. Currently, major Bangladeshi construction firms like Max Group and Bashundhara Group have deployed multiple mobile plants to enhance project responsiveness.

Hot Mix vs. Warm Mix: A New Choice in Environmental Trends

As environmental awareness grows in Bangladesh, concerns over the high energy consumption and pollution of traditional hot mix asphalt plants are increasing. Warm-mix asphalt plants reduce mixing temperatures by 30-50°C through specialized additives, cutting fuel costs by over 30% while significantly lowering exhaust emissions. In environmentally stringent cities like Dhaka and Chittagong, warm-mix equipment adoption is rising annually, positioning it as a key future market direction.

Core Requirements for Asphalt Mixing Plants in Bangladesh: Adaptation to Local Conditions is Paramount

Bangladesh’s unique climate, energy structure, and policy requirements dictate that asphalt mixing plants must possess targeted functional characteristics to establish a foothold in the local market:

Multi-fuel Adaptability

Bangladesh’s energy supply primarily relies on natural gas, diesel, and heavy fuel oil, but energy accessibility varies significantly across regions. For instance, cities like Dhaka and Chittagong have extensive natural gas pipeline networks, while remote rural areas rely primarily on diesel. Therefore, plants must incorporate “multi-fuel switching” capabilities to flexibly adapt to on-site energy availability, preventing construction delays due to fuel shortages. Current mainstream equipment supports dual-fuel natural gas-diesel systems, with some high-end models also compatible with heavy oil to further reduce operational costs.

Stringent Dust Control and Environmental Design

To address worsening air pollution, Bangladesh’s environmental authorities have implemented strict dust emission standards, requiring asphalt mixing plants to maintain dust concentrations below 50mg/m³. Traditional cyclone dust collectors no longer meet these requirements, making baghouse dust collectors the standard configuration. High-quality baghouse systems not only efficiently filter dust but also collect it for reuse as recycled aggregate, enabling resource recycling. This feature has made them highly popular in the Bangladeshi market.

Robust Structure Resistant to Humidity and Heat

Bangladesh’s tropical monsoon climate features year-round high temperatures and rainfall, with humidity often exceeding 80%. This places extreme demands on the structural integrity of mixing plant equipment. The main equipment frames require hot-dip galvanization to prevent corrosion, electrical control systems must incorporate waterproof and moisture-proof devices, and mixer tank inner walls utilize wear-resistant alloy materials to minimize adhesion. Some equipment customized for the Bangladesh market also includes ventilation and heat dissipation systems to prevent motor failures in high-temperature environments.

Intelligence and User-Friendliness

Given the varying skill levels among operators in Bangladesh’s construction sector, the control system must be “intelligent and easy to operate.” Current mainstream equipment features touchscreen control systems with built-in databases of construction mix designs. Operators simply input project parameters to automatically generate production plans. These systems also include automatic fault alerts and data statistics, simplifying operation while facilitating project management.

Convenient Spare Parts Supply

Core components of asphalt mixing plants—such as mixing blades, conveyor belts, and burners—are wear-prone parts requiring regular replacement. Delays in spare parts supply can cause equipment downtime and disrupt project schedules. Therefore, whether suppliers can establish local spare parts warehouses in Bangladesh or provide rapid international logistics services is a critical factor for contractors when selecting equipment.

Market Landscape of Bangladesh’s Asphalt Mixing Plants: Chinese Brands Emerge as Key Players

The current asphalt mixing plant market in Bangladesh is primarily composed of local manufacturers, Chinese brands, European brands, and Indian brands. Each category exhibits distinct positioning and strengths, collectively supporting market demand:

Local Manufacturers: Focusing on the Low-to-Mid-Range Market

Bangladeshi manufacturers such as Bangladesh Engineering Works and Rangs Group leverage localized service advantages to capture portions of the low-to-mid-range market. These companies primarily assemble equipment, relying on imported core components. Their production capacity typically falls below 60TPH, offering relatively low prices. However, they exhibit shortcomings in technical stability and advanced functionality, primarily serving small-scale rural road projects.

International Brands: Differentiated Focus

European brands like Wirtgen and Amman lead in technology and equipment quality but command premium prices (typically 3-4 times that of Chinese brands) with extended spare parts lead times, making them suitable for government flagship projects. Indian brands such as TIL and L&T emphasize cost-effectiveness, though they lag behind Chinese brands in equipment resistance to humid heat and after-sales service. Chinese brands like ZOOMLINE, and ZOOMLINE have become the mainstream choice in the Bangladesh market, capturing over 50% market share, thanks to their comprehensive advantages of “mature technology, moderate pricing, and comprehensive service.”

How to Select Reliable Suppliers?

For Bangladeshi contractors, three core factors are crucial when choosing asphalt mixing plant suppliers: First, certification qualifications—prioritize companies with ISO 9001 quality system certification and EU CE certification to ensure equipment meets international standards. Second, after-sales service—require suppliers to maintain service centers in Bangladesh, offering 24-hour fault response, on-site installation/commissioning, and operator training. Third, spare parts assurance: Confirm suppliers maintain stable local spare parts warehouses or can facilitate rapid replenishment via ports like Dhaka or Chittagong.

Equipment Selection Guide for Bangladesh Projects: Scientific Decision-Making to Enhance ROI

Selecting the appropriate asphalt mixing plant not only ensures project quality but also significantly improves return on investment (ROI). Contractors can follow these steps for scientific selection:

Define Project Requirements

Determine equipment capacity based on road classification (highway/rural), construction timeline, and daily output demands. Prioritize batch plants for high-end projects, while mobile plants are preferable for dispersed small-scale projects.

Assess Energy Conditions

Investigate on-site energy types and costs. Opt for dual-fuel equipment in areas with ample natural gas supply, while ensuring diesel compatibility for remote locations.

Consider site factors

Urban projects should focus on equipment footprint and environmental compliance, while rural projects should prioritize transport and installation convenience.

Calculate total lifecycle costs

Beyond the purchase price, factor in long-term expenses like fuel consumption, spare parts replacement, and maintenance to avoid the pitfall of “low-cost acquisition, high-cost operation.”

Ensure compliance

Verify equipment meets Bangladesh environmental agency requirements for dust emissions, noise control, etc., to avoid penalties for violations.

Installation, Operation, and Maintenance: Key to Extending Equipment Lifespan

Efficient operation of asphalt mixing plants relies on scientific installation, standardized operation, and timely maintenance. Particularly in Bangladesh’s unique environment, emphasize the following points:

Site and Foundation

Select elevated, well-drained locations to prevent equipment flooding during monsoons. Foundations must use reinforced concrete structures with load-bearing capacity meeting equipment specifications, incorporating drainage slopes.

System Commissioning

After installation, comprehensively test fuel systems, dust collection systems, and control systems to ensure coordinated operation. Prioritize combustion efficiency checks when switching fuel types.

Routine Maintenance

Implement daily inspection protocols focusing on mixing blade wear, conveyor belt tension, and dust collector filter bag cleanliness. During rainy seasons, intensify moisture checks on electrical systems and regularly replace lubricants and seals.

Personnel Training

Provide systematic training for operators to master equipment operation protocols, fault diagnosis, and emergency response procedures, preventing equipment damage due to operational errors.

Why Have Chinese Asphalt Mixing Plants Become the Preferred Choice for Bangladeshi Contractors?

In the Bangladeshi market, the market share of Chinese asphalt mixing plants continues to rise. The core reason lies in their precise alignment with local contractors’ needs, creating an “irreplaceable” competitive advantage:

Outstanding Cost-Performance Ratio

Priced at just one-third to one-half of European brands, Chinese equipment delivers equivalent or superior core performance, perfectly aligning with Bangladeshi contractors’ need to “control costs while ensuring quality.” For example, a 120TPH batch-type mixing plant from a Chinese brand costs approximately $800,000 to $1,000,000, compared to over $3,000,000 for European brands.

Mature and Stable Technology

After decades of technological accumulation, Chinese asphalt mixing plants have achieved self-reliance in core technologies, reaching internationally advanced levels in mixing precision and energy consumption control. Additionally, Chinese companies can customize equipment based on Bangladesh’s climate and energy characteristics—such as enhanced rustproofing and optimized fuel systems—significantly improving equipment adaptability.

Efficient Delivery and Service

China’s comprehensive manufacturing supply chain enables equipment production cycles of just 30-45 days, far faster than the 3-6 months required by European brands. Moreover, most Chinese companies have established service centers and spare parts warehouses in Dhaka and Chittagong, offering “one-stop” services including on-site installation, commissioning, and maintenance with a maximum fault response time of 24 hours.

Ample Spare Parts Supply

Chinese-brand spare parts feature high interchangeability and can be rapidly transported via the “China-Bangladesh Trade Corridor.” Common components like mixing blades and filter bags are readily available from local warehouses, eliminating contractors’ logistical concerns.

Conclusion: Seizing Bangladesh’s Golden Opportunity in Road Construction

As Bangladesh’s infrastructure development continues to advance, the asphalt mixing plant market will enter a growth window lasting over a decade. For contractors, selecting an asphalt mixing plant that meets local requirements, offers high cost-effectiveness, and provides reliable service is not only fundamental to ensuring smooth project progress but also key to enhancing market competitiveness.

Chinese asphalt mixing plants have become the preferred brand in the Bangladesh market, leveraging triple advantages in “technology, price, and service.” Looking ahead, as China-Bangladesh cooperation deepens under the Belt and Road Initiative, collaboration in infrastructure will intensify. Chinese equipment will contribute significantly to Bangladesh’s modern transportation network development and economic growth. For contractors with operational needs, now is the optimal time to assess requirements and select reliable equipment. Proactive planning will secure a competitive edge in the market.