The annual maintenance season for asphalt mixing plants refers to a specific period during production downtime (typically the off-season) when equipment undergoes comprehensive, systematic inspection, maintenance, repairs, and component replacement. For owners and operators of asphalt mixing plants, scheduled annual maintenance is not merely a routine formality but a critical component ensuring long-term stable operation. Equipment maintenance maintains a direct and critical relationship with production efficiency and operational costs: Scientific maintenance reduces equipment failure frequency, streamlines production processes, and increases output per unit time. Simultaneously, proactively identifying potential issues prevents costly emergency repairs, minimizes order losses due to downtime, and ultimately enables precise control over operational expenses. In today’s increasingly competitive road construction industry, annual maintenance has become a vital foundation for the sustainable operation of mixing plants.

Core components like dryers, mixers, and burners in asphalt plants represent high-value assets, accounting for over 60% of total equipment investment. Under demanding conditions—24/7 continuous operation exceeding 3,000 annual operating hours—issues like metal fatigue, high-temperature corrosion, and mechanical wear are inevitable.

During field operations, the dryer drum rotates continuously at 400°C. Thermal expansion and contraction stresses cause fatigue in the drum wall metal, leading to micro-cracks at weld seams. Mixer blades undergo prolonged friction with high-hardness aggregates, resulting in quarterly wear depths of 0.5-1mm on the surface carbonized layer. Burner nozzles endure flame impacts exceeding 1200°C, suffering over 5% monthly oxidation loss. Industry statistics indicate that equipment without annual maintenance experiences 4-6 times higher failure rates in critical components compared to maintained units. If minor cracks or abnormal wear go unaddressed, they can easily trigger chain failures, leading to premature core component failure.

A systematic annual maintenance process—encompassing precision flaw detection, customized lubrication protocols, targeted repairs, and replacement of performance-degraded components—can reduce key component wear rates by 40%-60% and extend overall equipment lifespan by 30%-50%. Specifically: – Millimeter-level defect detection of mixer shafts using ultrasonic flaw detectors, paired with laser cladding technology to repair worn journal surfaces – High-temperature lithium-based grease for dryer bearings and heavy-duty gear oil for mixer gearboxes, selected based on component operating conditions – Hardfacing reinforcement of burner nozzles and replacement of excessively worn screw conveyor blades These measures effectively prevent rapid asset depreciation caused by “running with defects,” establishing a robust defense for preserving equipment investment value.

The quality of asphalt mix directly determines the durability and safety of road projects, with equipment condition being the core factor influencing mix quality. From raw material intake to finished product dispatch, every critical component of the asphalt mixing plant plays an indispensable role. Minor deviations in the metering system can lead to inaccurate ratios of aggregates, powder, and asphalt; excessive wear on mixing blades prevents thorough blending of the mixture; and reduced burner performance makes it difficult to control temperature fluctuations in the finished product.

In actual projects, quality incidents caused by equipment aging are commonplace. One expressway section developed extensive potholes within a year of opening. Inspection revealed that the mixing plant’s weighing sensors had not been calibrated for an extended period, leading to insufficient mineral powder addition and reduced asphalt binder adhesion. In another municipal road project, failure of the mixing shaft seals allowed moisture to infiltrate the mix, causing severe water damage to the pavement during the rainy season. These cases clearly demonstrate that worn components or inaccurate parameters in mixing plants can easily lead to issues like aggregate segregation, excessive temperature fluctuations, and uneven mix proportions. These problems subsequently cause engineering hazards such as poor pavement smoothness and insufficient crack resistance.

Annual maintenance, as a critical safeguard for equipment performance, effectively mitigates these risks through systematic professional procedures. Technicians conduct comprehensive calibration of metering sensors using standard weights for multi-point testing, ensuring weighing accuracy for aggregates, powder materials, and asphalt within ±0.5%. They conduct in-depth inspections of the mixing system, replacing blades and liners exceeding wear limits and adjusting mixing shaft clearances to ensure uniform mixing within specified times. Simultaneously, they optimize the combustion temperature control system by using thermal imaging cameras to inspect the temperature distribution in the drying drum and calibrating temperature sensors, ensuring finished material temperature fluctuations remain within ±10℃.

These refined maintenance operations ensure equipment operates at peak performance, guaranteeing stable compliance with critical asphalt mixture parameters such as gradation, temperature, and moisture content. Taking gradation control as an example, post-maintenance batch plants produce mixtures with 0.075mm sieve pass rate fluctuations reduced from ±8% to ±3%, fully meeting highway asphalt pavement construction specifications. Stable and reliable equipment performance undoubtedly provides a solid foundation for high-quality road construction.

Road construction is significantly influenced by seasonal factors, with asphalt paving peak seasons typically concentrated in spring and summer. During these periods, orders pile up and deadlines are tight, often leading project owners to enforce strict delivery terms. In such high-intensity operations, sudden equipment failures at asphalt mixing plants not only directly delay project schedules but can also trigger severe consequences like breach-of-contract penalties, reputational damage, and even impact a company’s future bidding eligibility.

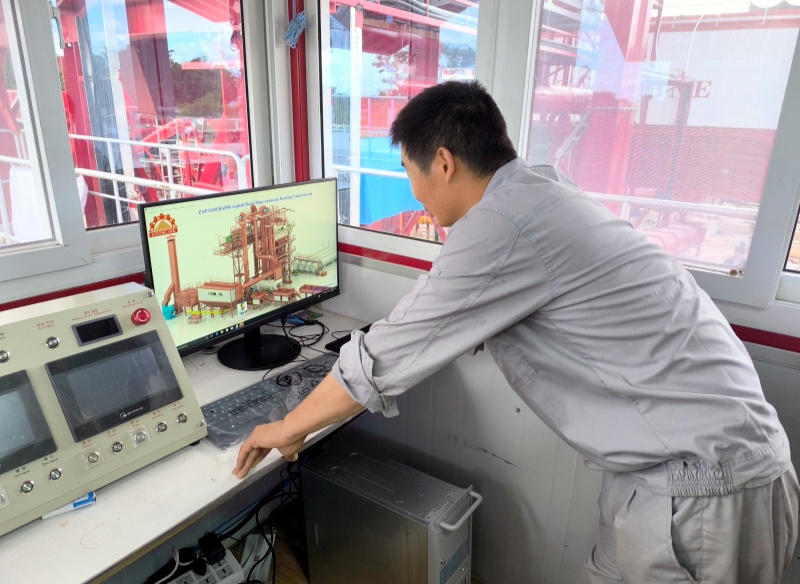

Conducting annual maintenance during the off-season is a highly strategic move. Maintenance teams can employ specialized diagnostic equipment to conduct systematic, in-depth inspections of the mixing plant: thermal imaging cameras scan aging circuits to pinpoint potential hazards like poor contacts or damaged insulation; 3D laser scanners assess blade wear to determine replacement or repair needs; endoscopes examine dust collection ducts to promptly clear accumulated debris from prolonged use. This preventive maintenance mechanism functions like a comprehensive physical examination for equipment, enabling early detection and resolution of potential issues to effectively mitigate the risk of concentrated failures during peak seasons.

Statistics from authoritative industry bodies further underscore the importance of annual maintenance: plants implementing regular annual maintenance see emergency repair frequency reduced by over 70%, with the cost of a single emergency repair typically 3-5 times that of scheduled maintenance. This means that through scientifically planned annual maintenance, enterprises can not only significantly reduce downtime losses caused by equipment failures but also effectively optimize full-cycle operational costs, allowing more limited resources to be invested in production and technological upgrades.

Asphalt mixing plants involve high temperatures, high pressures, mechanical operations, dust, and exhaust emissions during production, making safety and environmental compliance the baseline for operations. During annual maintenance, technicians employ specialized testing equipment to conduct systematic inspections of safety protection devices: Emergency stop buttons are verified using signal testers to ensure response times remain under 0.5 seconds, guaranteeing rapid power disconnection during emergencies. Guardrails undergo mechanical testing to assess weld integrity, with load-bearing tests requiring no deformation under 500 kg per meter pressure. Safety valve calibration is even more rigorous, requiring simulated operating conditions to test whether the trip pressure is accurate, with errors controlled within ±2%. This ensures timely elimination of safety hazards such as mechanical injury, fire, and explosion.

Regarding environmental equipment maintenance, dust collection system upkeep is particularly critical. Technicians perform comprehensive disassembly of pulse-jet baghouse dust collectors, meticulously inspecting filter bags for damage or clogging. Bags in operation exceeding 12 months undergo mandatory replacement, with membrane-coated anti-static filter media employed to enhance filtration efficiency. For exhaust gas treatment units, an intelligent monitoring system analyzes real-time emission data of harmful gases like nitrogen oxides and sulfur dioxide, dynamically adjusting the air-fuel ratio of burners to maintain combustion efficiency above 98%. Simultaneously, acoustic detectors conduct comprehensive measurements of operational noise levels. Soundproofing insulation and vibration damping devices are installed at critical points to ensure dust emission concentrations remain below 20mg/m³ and noise levels do not exceed 85dB(A). All environmental indicators comply with the Comprehensive Emission Standards for Air Pollutants and local environmental regulations, eliminating risks of fines or production halts due to non-compliance at the source.

Annual maintenance is typically scheduled during low-production off-seasons for two key reasons: First, reduced order volumes minimize production disruption, allowing ample time for comprehensive inspections without rushed completion. Second, off-season maintenance enables equipment commissioning before peak demand, ensuring optimal readiness for concentrated production. Furthermore, off-season maintenance reduces costs. During production lulls, maintenance personnel are more readily available, allowing flexible deployment of key technical staff to avoid labor cost surges from rushed schedules. Simultaneously, component suppliers offer extended lead times, ensuring timely delivery of required parts and preventing delays or premium purchases due to shortages.

Off-season timing varies by region due to climate and project cycles: In China, for instance, northern regions experience winter cold, typically designating November through March as the off-season. During this period, outdoor asphalt paving faces challenges due to reduced material setting speeds and increased construction difficulty caused by low temperatures, leading to a sharp decline in project demand. Mixing plants can utilize this time for in-depth disassembly and maintenance of core equipment such as mixing hosts and drying drums, cleaning internal material buildup and worn components. Southern regions experience reduced construction activity during rainy seasons (e.g., April-June) or winter cold spells (December-February), creating prime maintenance windows. Humid rainy conditions can cause electrical equipment failures; this period allows for dehumidification, insulation testing, and replacement of aged components in precision electrical elements like distribution cabinets and sensors. Although winter temperatures in southern regions are milder than northern extremes, they still affect asphalt flowability. Prioritize maintenance of thermal oil systems and insulation devices to ensure equipment thermal performance.

If maintenance must occur during peak seasons due to special circumstances, plan production schedules in advance and establish a dynamic order tracking mechanism. Use data analysis to predict order lulls and select order gaps for localized, rapid maintenance of critical components. For example, for components prone to failure like vibrating screens and hot material silos, adopt modular rapid replacement solutions by pre-stocking spare parts to complete repairs in minimal time. Simultaneously, maintain close communication with customers, notify them of maintenance schedules in advance, and coordinate adjustments to non-urgent order delivery times to avoid impacting core order fulfillment.

When developing maintenance plans, establish a scientific maintenance framework by integrating equipment operating hours, historical failure records, manufacturer recommendations, and the following year’s production schedule. Analyze wear cycles for different components through detailed statistics of equipment operating hours; identify vulnerable parts and high-frequency failure points by referencing past failure records; strictly adhere to manufacturer-provided technical specifications to ensure professional maintenance standards; and reasonably schedule maintenance windows based on the upcoming year’s production plan. Clearly define maintenance start/end dates, core activities, responsibility assignments, and acceptance criteria. Utilize tools like Gantt charts to refine task milestones, breaking maintenance work into quantifiable, trackable subtasks to ensure plan operability.

For shutdown management, proactively communicate with customers via written notices or dedicated meetings to secure at least a two-week maintenance buffer period. Simultaneously develop contingency production plans to minimize impacts on customer order fulfillment. Coordinate spare parts supply by establishing a priority list. For critical components like agitator shaft seals, vibrating screen mesh, and burner nozzles, place orders with suppliers 30 days in advance. Implement inventory alert mechanisms to ensure timely availability of key parts. For staffing, assemble a core maintenance team comprising senior technical experts and skilled equipment operators from the plant. When necessary, invite the manufacturer’s after-sales team to provide on-site guidance, establishing a collaborative model of “plant personnel leading + manufacturer support.” In the technical support phase, prepare not only equipment drawings and maintenance manuals but also compile a historical maintenance case library and documentation of common fault solutions. For potential complex issues, establish remote support channels with the manufacturer’s technical experts in advance.

Simultaneously, establish maintenance milestones such as: “Complete dust collection system overhaul within 3 days, including filter cartridge replacement, pulse valve testing, and pipeline seal inspection” and “Complete mixing system maintenance within 5 days, covering mixing blade wear assessment, shaft seal adjustment, and gearbox lubricant replacement.” Utilize project management software for real-time progress tracking, conduct daily maintenance progress meetings to promptly resolve unexpected issues, and ensure maintenance tasks are completed on schedule and to quality standards.

Prior to maintenance, comprehensively analyze operational data from the previous production season: Retrieve key metrics from the production management system, including total production hours, aggregate output, energy consumption (fuel, electricity, asphalt usage), failure timelines and causes, and downtime duration. Utilize trend analysis charts to visually display equipment performance curves over time, precisely identifying “vulnerable points.” For example, if a specific vibrating screen model has accumulated five failures over the past three months, each accompanied by a sharp drop in screening efficiency, it should be prioritized for maintenance. If fuel consumption per unit has increased by 15% year-over-year, conduct in-depth inspections of core energy-consuming components like burners and thermal oil systems.

Simultaneously, establish a multi-dimensional information collection mechanism: – Require operators to complete daily Equipment Operation Logs detailing specific operating conditions where anomalies like unusual noises, vibrations, or temperature fluctuations occur. – Organize specialized workshops with operational teams to gather hidden issues during equipment operation, such as ratio fluctuations caused by uneven feeding in cold material silos. By integrating quantitative data analysis with frontline operational expertise, differentiated maintenance plans were developed to avoid “blind repairs,” ensuring maintenance resources are precisely allocated to critical components that genuinely impact equipment performance.

A detailed critical spare parts list was prepared in advance, prioritizing stable supply for core components, specifically covering:

For spare part selection, we strongly recommend using original manufacturer parts or high-quality certified alternatives. Although initial procurement costs may be higher, these parts achieve precise compatibility with the equipment, significantly reducing failure rates and effectively preventing frequent downtime caused by substandard components. Additionally, specialized maintenance tools must be provided, including cranes, specialized wrenches, temperature detectors, pressure gauges, vibration testers, and welding equipment, to ensure efficient maintenance operations and substantially improve repair efficiency.

Safety is the prerequisite for maintenance work. Strictly enforce the Lockout/Tagout (LOTO) procedure:

◦ High-Temperature Equipment: Components such as dryers and asphalt storage tanks must cool to ambient temperature (recommended below 60°C). Monitor cooling progress in real-time using the equipment’s built-in temperature monitoring system or infrared thermometers. For rapid cooling devices, verify operational status to prevent equipment deformation from excessive cooling rates.

◦ Confined Spaces: For enclosed areas like storage silos and dust collectors, activate forced ventilation systems for at least 30 minutes. Use gas detectors to verify internal oxygen levels (≥19.5%), carbon monoxide, hydrogen sulfide, and other hazardous gas concentrations. Repeat testing before each entry and every 30 minutes during operations to ensure environmental safety.

3. Personal Protective Equipment (PPE): Maintenance personnel must correctly wear full protective gear:

◦ Head Protection: Wear a safety helmet compliant with GB 2811 standards, ensuring proper distance between the liner and shell, with impact resistance and insulation capabilities.

◦ Hand Protection: Select protective gloves based on task requirements, such as oil-resistant nitrile gloves (for asphalt contact) or heat-resistant aramid gloves (for high-temperature components).

◦ Eye Protection: Wear splash-proof goggles or face shields with anti-fog and scratch-resistant lenses to prevent injury from dust or liquid splashes.

◦ Foot Protection: Wear slip-resistant, impact-resistant, oil-resistant safety shoes with insulated soles and steel toe caps to withstand falling objects.

4. Emergency Preparedness: Equip the work area with fire extinguishers and first-aid kits, ensuring at least two personnel work in pairs. Pre-plan evacuation routes, establish emergency contact methods and assembly points, and conduct regular safety drills to enhance emergency response capabilities.

As the “feed throat” of the mixing plant, the aggregate supply system directly determines raw material supply stability. During routine inspections, adopt a step-by-step troubleshooting approach: For the cold aggregate bins, besides observing the smooth operation of the discharge gates, use a feeler gauge to check the gap width, ensuring the clearance is controlled within ±2mm. For material leakage issues, prioritize inspecting the aging condition of sealing strips, with quarterly replacement recommended. For conveyor belt maintenance, implement visual inspection technology using high-definition cameras to monitor surface damage in real time. Any cracks exceeding 5cm in length must be repaired immediately. To address belt misalignment, use the three-point calibration method to adjust idler angles, ensuring belt deviation does not exceed 5mm. Simultaneously, utilize tension gauges to periodically calibrate tensioning devices, maintaining tension within the safe range of 180-220 N/m. Aggregate elevator maintenance should prioritize monitoring chain elongation; replacement is mandatory when elongation exceeds 2% of the original length. For bucket wear, apply wear-resistant ceramic patches as preventive reinforcement to extend service life.

The performance of the drying system directly impacts aggregate drying quality and energy consumption levels. During dryer drum maintenance, establish a three-dimensional inspection record: Use an infrared thermal imager to detect liner wear and mark areas with abnormal temperatures; Measure drum ovality with a laser distance meter, requiring immediate correction when deviation exceeds 3mm; Implement a timed, metered oil injection system for bearing lubrication, with high-temperature lithium-based grease replenishment recommended every 500 operating hours. For burner maintenance, equip dedicated carbon deposit cleaning devices to periodically clear nozzle passages; Implement an intelligent ignition detection system to monitor ignition success rates in real time, triggering automatic alarms after three consecutive ignition failures. For drying temperature control, establish a dynamic compensation model that automatically adjusts flame intensity based on ambient humidity and aggregate moisture content. Utilize ultrasonic detection technology during insulation layer inspections to promptly identify internal voids and damage, ensuring thermal conductivity of insulation materials does not exceed 0.04 W/(m·K).

The efficient operation of the dust removal system is central to ensuring the mixing plant meets environmental standards. Baghouse maintenance requires a tiered management strategy: Establish a filter bag lifespan prediction model to estimate replacement cycles based on parameters like filtration air velocity and dust concentration. For clogging issues, configure pulse-jet backflush pressure monitoring devices that automatically initiate backflushing when pressure fluctuations exceed set thresholds. For induced draft fan maintenance, incorporate vibration analysis technology. Use a spectrum analyzer to check impeller dynamic balance, requiring calibration when vibration exceeds 4.5 mm/s. Implement an online temperature monitoring system for fan bearings, triggering alerts when temperatures surpass 80°C. Establish a chemical consumption database for exhaust gas treatment units, automatically calculating desulfurization and denitrification chemical replenishment based on production load. Equip dust hoppers with level monitoring systems that automatically initiate ash discharge when levels reach 80%. Implement anti-clogging designs for screw conveyors to ensure smooth ash removal.

The precision of the mixing system directly determines the uniformity and stability of the mixture. Component inspections must follow quantitative standards:

– Wear on mixing arms and blades is measured using vernier calipers. Replacement is mandatory when thickness falls below 70% of original dimensions.

– Liner wear is detected using ultrasonic thickness gauges, with minimum thickness maintained at 8mm. Mixing time calibration must incorporate material characteristic curves, with dedicated mixing programs for different aggregate gradations. The mixing drum employs a multi-seal structure, tested for integrity using a helium mass spectrometer leak detector to ensure leakage rates below 0.1m³/h. Transmission system maintenance incorporates oil analysis technology, with regular monitoring of lubricant viscosity, acid value, and ferrographic data. Lubricant replacement is required when iron content exceeds 50 ppm. Vector control technology is applied to the mixing motor, continuously monitoring current and voltage fluctuations to maintain operational efficiency above 90%.

Stable operation of the asphalt supply system relies on precise temperature control and flow management. Asphalt tank maintenance requires establishing a thermal model: employ a double-layer insulation structure with polyurethane foam on the outer layer and a reflective insulation film on the inner layer to ensure the tank surface temperature does not exceed 50°C. Heating coils incorporate electromagnetic descaling devices to periodically remove carbon deposits from tube walls, maintaining thermal efficiency. Asphalt pump maintenance utilizes condition monitoring technology, employing pressure and vibration sensors for real-time parameter tracking. Automatic alarms activate when outlet pressure fluctuations exceed ±0.5MPa. Valve seals employ metal hard-seal structures paired with pneumatic actuators for precise control. Asphalt pipelines incorporate trace heating insulation with an intelligent temperature control system maintaining pipeline temperatures between 140-150°C. Metering device calibration employs dynamic weighing technology, averaging multiple weighings to control measurement errors within ±0.3%.

As the intelligent hub of the mixing plant, the control system requires full lifecycle management. PLC control cabinet maintenance follows dust-free operation standards: specialized anti-static vacuum cleaners remove internal dust, ensuring component surface cleanliness meets specifications. Wiring connections are secured with torque wrenches, and terminal crimping points receive dual protection with heat-shrink tubing. Sensor calibration establishes a traceability system: regular third-party metrology inspections issue calibration certificates. Self-calibration technology enables automatic ±1℃ correction for temperature sensors. Software management implements version control mechanisms: Git is used for code management, with regular stress testing and vulnerability scanning. Electrical component maintenance employs redundant design, configuring critical circuits with dual contactors for automatic switching upon primary contactor failure. An intelligent meter monitoring system analyzes real-time equipment energy consumption data to optimize power usage efficiency.

Symptoms: Under high-load production conditions, accelerated wear occurs on critical components such as mixing blades, liner plates, and conveyor belts. Mixing blade edges exhibit noticeable curling deformation, with surfaces eroded by aggregates into grooves of varying depths; in severe cases, fractures may occur. Lining plates rapidly lose their wear-resistant coating, exposing the base metal; conveyor belts exhibit delamination and tears, with localized rubber thinning revealing the internal reinforcement layer. Continuous impact loosens and dislodges inner wall linings in dryer drums, causing localized blockages in aggregate conveyance channels and generating abnormal impact noises and stuttering during operation. Additionally, the meshing precision between drive chains and sprockets deteriorates, generating abnormal vibrations and noise during operation, significantly reducing overall equipment stability.

Causes: The primary factor causing excessive wear is prolonged overloading. When equipment operates at capacities exceeding rated standards by more than 10%, mechanical stress on components increases substantially, shortening fatigue life. Second, large impurities like stones or metal fragments in the aggregate cause intense impact and abrasion during mixing and conveying, accelerating wear. Furthermore, inadequate lubrication system maintenance is a key contributing factor. Failure to replenish or replace lubricants according to the equipment maintenance manual increases friction coefficients between components, hastening wear. Additionally, factors like reduced foundation stability and installation inaccuracies can cause uneven stress distribution, triggering localized abnormal wear.

Solutions: First, production management must strictly adhere to rated capacity standards. Implement intelligent monitoring systems to track real-time operational parameters, triggering automatic alerts when capacity nears critical thresholds to prevent overload. Second, install multi-layer vibrating screens and metal detectors at aggregate feed points. Vibrating screens effectively filter oversized particles, while metal detectors trigger linked automatic rejection systems to remove contaminants upon detection, reducing wear triggers at the source. For wear-prone components, adopt a cyclical maintenance strategy: shorten lubrication intervals by 50% under high-load conditions and conduct weekly non-destructive testing on critical parts to detect potential cracks early. Simultaneously, upgrade components like mixing blades and liners to wear-resistant materials such as high-chromium alloys or ceramic composites to extend service life. Furthermore, equipment installation accuracy is regularly calibrated, and foundations are reinforced to ensure uniform stress distribution across components, reducing abnormal wear risks.

Risk: As operational years increase, asphalt mixing plant electrical systems face multiple hazards. Aged wiring develops hardened, cracked insulation, prone to short circuits; oxidized and eroded contactor contacts increase resistance and cause poor connections; and degraded sensor performance distorts critical signals like temperature and pressure. These issues not only cause control system logic errors and equipment malfunctions, leading to unplanned shutdowns, but can also trigger fires due to electrical overheating in severe cases. Industry statistics indicate electrical faults account for over 30% of downtime, with 60% directly linked to component aging.

Solutions:

Causes: Environmental system efficiency decline typically results from multiple factors. First, dust collection filter bags—critical components for trapping particulates—operate under sustained high loads. If not replaced beyond their design lifespan (generally recommended every 8,000–10,000 hours), their fiber structure gradually clogs with dust, causing air permeability to plummet. Second, dust accumulation on the induced draft fan impeller creates uneven deposits, disrupting dynamic balance. This reduces airflow while intensifying equipment vibration and wear. Third, fuel quality fluctuations or imbalanced air-fuel ratios in burners often cause incomplete combustion, generating substantial unburned carbon particles. Fourth, insufficient reserves or diminished reactivity of desulfurization and denitrification agents in the exhaust gas treatment system fail to effectively neutralize acidic gases and nitrogen oxides, ultimately causing overall system failure.

Manifestations: Visibly, dust emission concentrations far exceed national standards (e.g., particulate matter emission limit of 50mg/m³), with continuous black smoke emanating from chimneys and noticeable dust deposition forming around the factory perimeter. More critically, persistent anomalies in online environmental monitoring data may trigger local ecological authorities’ warning mechanisms. This exposes enterprises to production suspensions, hefty fines, or even inclusion on environmental blacklists—severely damaging corporate reputation and operational stability.

Solution: Establishing a comprehensive preventive maintenance system is key. Implement a dust filter bag replacement schedule using membrane-coated anti-static filter materials to enhance filtration efficiency. Perform monthly ultrasonic cleaning of induced draft fan impellers and calibrate shaft alignment with laser alignment tools to ensure stable airflow. Utilize an intelligent burner control system to monitor oxygen levels and temperature curves in real time, dynamically adjusting the fuel-air ratio to maintain combustion efficiency above 98%. Implement an intelligent inventory alert system for chemicals, automatically triggering procurement when stock falls below safety thresholds, and conduct regular corrosion inspections of internal reactor components. Additionally, quarterly assessments by third-party environmental agencies are recommended to ensure environmental equipment operates at peak performance.

Equipment manufacturers’ maintenance manuals are professional standards developed based on equipment structure and performance characteristics, serving as the “operational bible” for ensuring stable asphalt mixing plant operation. This systematic guide covers critical information including maintenance cycles, maintenance tasks, component replacement intervals, and lubrication requirements. Every piece of data and recommendation within has undergone rigorous technical validation and practical testing. Strict adherence to OEM recommendations not only prevents equipment damage from improper maintenance but also ensures professional and effective upkeep, maximizing equipment lifespan.

Taking mixing system maintenance as an example, manufacturers recommend comprehensive lubrication of core components—such as mixing shafts, bearings, and gearboxes—every 500 operating hours. This involves applying specified high-performance grease with precise pressure and flow control to form an effective lubricating film, reducing friction coefficients between parts. Neglecting this cycle accelerates surface wear on metal components under high-temperature, high-load mixing conditions, potentially causing abnormal vibrations or even bearing seizure. Additionally, the guidelines explicitly require replacing mixing blades every 2000 operating hours. This is because prolonged contact with materials like sand, gravel, and asphalt gradually wears down the blades’ wear-resistant coating. Once wear exceeds the safety threshold, it not only compromises mixing uniformity but may also cause localized stress concentration, leading to blade fracture and threatening production safety. Using the manufacturer’s maintenance guidelines as the core reference for daily maintenance is an essential prerequisite for ensuring efficient and stable equipment operation.

Establish a systematic maintenance record system using digital spreadsheets or specialized equipment management software to comprehensively document the following key information:

These detailed maintenance records offer multiple benefits:

The professional competence and adherence to operational standards of operators are core factors determining the stable operation and maintenance effectiveness of asphalt mixing plant equipment. It is recommended to establish a routine training system:

Through tiered and categorized training, promote in-depth mastery of equipment performance characteristics among relevant personnel. Establish a collaborative “routine inspection + specialized maintenance” operational mechanism to achieve refined management throughout the equipment lifecycle.

When equipment encounters complex failures such as total control system shutdowns, structural deformation of dryer drums, or deep environmental system retrofits, or when maintenance teams face technical bottlenecks, it is recommended to immediately engage the asphalt mixing plant manufacturer’s original technical support team or a qualified third-party maintenance service provider. Leveraging years of accumulated technical databases, precision diagnostic instruments, and OEM-certified parts supply chains, these specialists can rapidly pinpoint root causes through systematic fault diagnosis. They deliver professional reports detailing repair solutions and preventive maintenance recommendations, effectively mitigating secondary damage risks from non-professional interventions.

In the domains of intelligent upgrades for aging equipment and environmental compliance retrofits, specialized teams further leverage their technical expertise: Drawing on keen insights into cutting-edge industry trends and in-depth analysis of environmental policy developments, they tailor digital control system upgrade plans and environmental equipment efficiency enhancement solutions for enterprises. This ensures equipment performance iterations align with industrial development trajectories while achieving precise upgrades that effectively control operational costs.

The direct costs of annual maintenance primarily consist of three major components:

Taking an asphalt mixing plant with an annual output of 300,000 tons as an example, its annual direct maintenance costs typically account for 3%-5% of the equipment’s total value. The specific amount may fluctuate based on the degree of equipment aging and differences in maintenance projects.

While annual maintenance requires upfront investment, its long-term benefits significantly outweigh costs:

First, it reduces failure rates and minimizes emergency repair expenses. For instance, replacing a mixing paddle costs approximately ¥20,000. If delayed replacement causes paddle fracture, not only does replacement cost apply, but potential damage to the mixing drum could escalate repair costs to over ¥100,000. Second, it enhances production efficiency. Well-maintained equipment operates more smoothly, boosting output per unit time by 5%-10% while reducing energy consumption by 8%-15%, leading to substantial long-term operational cost savings. Third, extending equipment lifespan reduces replacement frequency and boosts asset return on investment — a high-quality asphalt mixing plant can last 10-15 years. Proper annual maintenance ensures stable operation throughout its design life, avoiding premature scrapping and associated repurchase costs.

Amid intensifying competition in the road construction industry, equipment reliability and product quality have become core competitive advantages. Effective annual maintenance ensures high reliability during peak paving seasons, preventing order losses due to equipment failures. Consistent equipment performance ensures asphalt mix quality consistently meets standards, earning trust from contractors and government projects while building a strong market reputation. During bidding processes, plants with comprehensive maintenance records and well-maintained equipment gain greater access to large-scale project opportunities. Additionally, maintained equipment consumes less energy and meets environmental standards, adapting to increasingly stringent environmental policies and market demands for green production. This expands business scope and secures competitive advantages.

When selecting an asphalt mixing plant maintenance partner, evaluate both experience and technical capabilities. First, highlight how extensive experience accelerates fault resolution, then emphasize the importance of industry knowledge reserves and integrated service advantages to enhance textual logic and professionalism.

When evaluating maintenance partners, prioritize their depth of practical experience in asphalt mixing plants. Focus on whether they possess expertise in the intricate structures and typical failure patterns of various brands and models. Simultaneously, assess the comprehensiveness of their industry knowledge system—including precise interpretation of the latest environmental policies and regulations, keen awareness of cutting-edge technological trends, and the ability to deliver integrated solutions encompassing equipment maintenance, technical upgrades, and compliance retrofits. Only partners with deep technical expertise and dynamic knowledge-updating capabilities can efficiently tackle complex technical challenges, significantly enhancing the precision and timeliness of maintenance services.

In annual asphalt mixing plant maintenance, spare parts supply serves as the lifeline sustaining the maintenance process. A quality maintenance partner must establish a comprehensive spare parts assurance system. This involves implementing a three-tiered reserve structure (strategic reserves, commonly used parts, emergency parts) to ensure ample supply of critical components such as the wear-resistant liners for mixing hosts (e.g., customized models from Nanjing Road Machinery) and PLC control system modules (Siemens S7-1500 series). Leveraging an intelligent warehouse management system, achieve a core component inventory turnover rate ≤72 hours to enable rapid response mechanisms. This ensures spare parts can be mobilized at the fastest possible speed when maintenance needs arise.

Simultaneously, adhere to using high-quality spare parts that are either OEM-certified or ISO 9001 quality system certified. Strictly enforce spare part compatibility testing procedures to eliminate the risk of secondary downtime caused by compatibility issues at the source. By establishing direct supply channels with equipment manufacturers, we guarantee precise compatibility between spare parts and equipment while simultaneously accessing upgraded components incorporating the latest technological advancements, providing a solid foundation for continuous equipment performance optimization.

Robust after-sales service provides sustained maintenance assurance. When selecting partners, prioritize teams offering 24/7 emergency technical support. This response mechanism enables rapid intervention during unexpected equipment failures, minimizing downtime through remote diagnostics or on-site repairs. Post-maintenance follow-up visits are equally critical, allowing service providers to collect operational data, identify potential risks early, and prevent issues from escalating through preventive maintenance.

Beyond basic services, value-added services serve as a key indicator of after-sales quality. Premium partners provide customized technical training, combining theoretical instruction with hands-on practice to equip operators with fundamental troubleshooting skills. Simultaneously, they dynamically optimize maintenance plans based on equipment operational big data—from adjusting lubrication cycles to refining wear-part replacement strategies—delivering scientifically sound maintenance solutions to owners. These services not only enhance the team’s autonomous maintenance capabilities but also effectively reduce the equipment’s total lifecycle operating costs by minimizing over-maintenance and spare parts waste.

The annual maintenance season for asphalt mixing plants is a critical phase for ensuring stable equipment operation, boosting production efficiency, and lowering operating costs. It not only extends equipment lifespan, safeguards product quality, and reduces safety and environmental risks but also enhances the plant’s market competitiveness. Owners should abandon the mindset of “prioritizing production over maintenance.” Instead, they should proactively schedule maintenance periods, prepare thoroughly, adhere to scientific maintenance procedures and best practices, and engage professional maintenance partners when necessary. Only by integrating annual maintenance into routine management can asphalt mixing plants consistently generate value over the long term, providing robust support for the high-quality development of the road construction industry.