In road construction projects, asphalt mixing plants are the core equipment for producing qualified asphalt mixtures. The control system, as the “central nervous system” and “intelligent brain” of the mixing plant, directly determines the quality stability, production efficiency, and overall cost control level of the asphalt mixture. Whether it’s highway, urban arterial road, or rural road construction, key indicators such as the accuracy of the mixture’s proportions and temperature stability rely on the precise control of the control system.

Batching Precision Control Function

Batching is the “first hurdle” in asphalt mixture production, and its precision is the cornerstone of quality.

Automatic metering and proportioning adjustment of aggregates (stone, sand)

The control system uses high-precision belt scales and weighing sensors to continuously or batch-weigh cold aggregates of different specifications and automatically adjusts the feeder speed to ensure that each grade of aggregate strictly enters the drying drum according to the preset proportion.

Precise quantitative conveying of asphalt and powder (cement, mineral powder)

The system controls the asphalt pump and valves to achieve precise weighing of liquid asphalt through an asphalt scale; simultaneously, the powder screw conveyor works in conjunction with the powder scale to ensure accurate powder addition.

Automatic moisture content compensation

Aggregate moisture is easily affected by weather. Advanced systems are equipped with microwave or infrared moisture content detectors to monitor aggregate moisture content in real time and automatically calculate and compensate for additional asphalt and powder dosages, avoiding proportioning distortion due to moisture fluctuations.

Rapid Switching of Mixing Parameters

To adapt to the production needs of different grades of asphalt mixtures such as AC-13, AC-20, and SMA, the control system can store hundreds of formulas, enabling one-click rapid switching and greatly improving production flexibility.

Temperature Closed-Loop Control Function

Temperature is the lifeline of asphalt mixture production.

Real-time Monitoring and Burner Adjustment of Aggregate Drying Temperature

The system monitors the aggregate temperature at the outlet of the drying drum, provides real-time feedback, and automatically adjusts the air-oil ratio of the burner to ensure that the aggregate is heated to the set temperature for asphalt coating.

Precise Control of Asphalt Heating Temperature

The system controls the asphalt thermal oil furnace or electric heating system to maintain the asphalt within a suitable temperature range during storage and transportation, preventing excessively high temperatures from causing asphalt aging or excessively low temperatures from causing poor fluidity.

Constant Control of Mixture Discharge Temperature

During the mixing process, the system comprehensively considers aggregate temperature, asphalt temperature, and ambient temperature to ensure that the final discharge temperature of the mixture strictly meets the construction specifications, guaranteeing paving and compaction quality.

Waste Heat Recovery and Temperature Energy-Saving Optimization

The intelligent system incorporates waste heat recovery technology, utilizing the exhaust gas generated by the drying drum to preheat cold aggregates, thereby significantly reducing fuel consumption and achieving energy-saving production.

Mixing Process Timing Control Function

Mixing is the key physical process for uniformly mixing various raw materials.

Intelligent Planning of Aggregate, Asphalt, and Powder Feeding Sequence

The control system precisely controls the timing of each material’s feeding, typically feeding aggregates first, then powders for “dry mixing,” and finally spraying asphalt for “wet mixing,” ensuring uniform mixing.

Adaptive Adjustment of Mixing Time

The system can automatically fine-tune the mixing time based on the type of mixture and observed uniformity feedback, avoiding insufficient mixing resulting in white aggregate or over-mixing causing asphalt leakage.

Mixing Cylinder Load Monitoring and Overload Protection

By monitoring the current of the main mixing motor, the system can determine the load condition within the mixing cylinder. In the event of an overload, the protection program is immediately activated to prevent equipment damage.

Unloading sequence and finished product silo connection control

After mixing is completed, the system automatically opens the unloading gate and accurately delivers the finished material into the designated finished product silo via a material transport trolley. The whole process is seamless, efficient and smooth.

Data Management and Traceability Functions

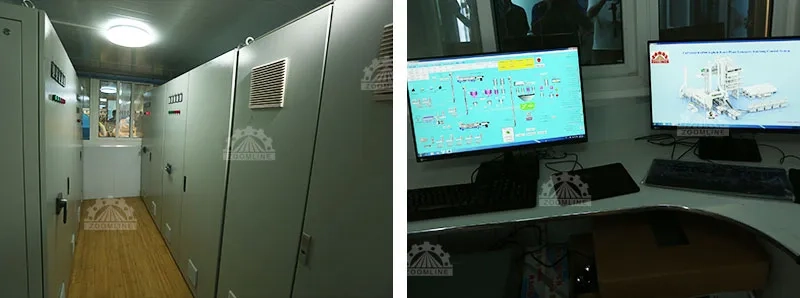

Real-time Monitoring of Key Parameters

On the Human-Machine Interface (HMI), operators can monitor the aggregate ratio, asphalt usage, various temperatures, instantaneous output, and the operating/stopping status of all core equipment for each batch of material in real time.

Visualized Dashboard

Data is presented intuitively in various forms such as analog instruments, trend curves, and numerical lists, making the production status clear at a glance.

Real-time Early Warning of Abnormal Data

When any parameter exceeds the set range, the system will immediately alert the operator through sound alarms, flashing warning lights, and screen pop-ups.

Automatic Production Data Storage

The system automatically records and stores the entire process data for each batch of mixture, including production time, formula code, actual material usage, and temperature curves.

Data Query Function

Supports precise retrieval by date, batch number, or project name, quickly locating the historical records of any batch of material.

Quality Traceability Report Generation

Quality reports conforming to construction acceptance specifications can be generated with one click, providing tamper-proof data evidence for quality responsibility tracing and project auditing.

Daily/Weekly/Monthly Output Statistics

Automatically calculates total output and analyzes the output proportion of each grade of mixture, providing data support for production planning.

Material Consumption Statistics

Accurately calculates the total consumption and loss rate of asphalt, aggregates, and powders, aiding in cost accounting and inventory management.

Equipment Operating Efficiency Analysis

Statistics on the effective working time, waiting time for materials, downtime due to malfunctions, and their causes at the mixing plant, providing guidance for improving overall equipment efficiency (OEE).

Equipment Status Monitoring and Protection Functions

Real-time Monitoring of Equipment Operating Status

Current and Voltage Monitoring of Core Components

Monitoring the electrical parameters of major electrical equipment such as motors, pumps, and fans; abnormal fluctuations are often precursors to failure.

Real-time Monitoring of Bearing Temperature and Lubrication Level

Monitoring the temperature and lubrication status of key rotating components through sensors to prevent bearing burnout due to poor lubrication.

Feedback on the Operating Status of Moving Parts

Monitoring whether the conveyor belt is misaligned or slipping, and whether the mixing cylinder is operating smoothly.

Overload Protection

When the load on the motor or mixing cylinder exceeds the safety threshold, the system will automatically cut off the power supply and force a shutdown.

Material Shortage/Blockage Protection

When the aggregate bin is short of material, the powder tank is empty, or the conveying pipeline is blocked, the system will issue an early warning and automatically shut down to prevent the equipment from running idle or the fault from escalating.

Over-temperature/Over-pressure Protection

Safety monitoring of high-pressure and high-temperature containers such as burners and asphalt heating tanks; exceeding limits will trigger an alarm and activate safety interlocks.

Automatic Fault Code Generation

When a fault occurs, the system automatically generates and records a unique fault code. Maintenance personnel can quickly locate the problem using the code manual, shortening repair time.

Consumer Parts Lifespan Countdown Reminder

The system automatically reminds users to replace consumable parts such as agitator blades and liners based on operating time or the number of agitator discs.

Regular Maintenance Cycle Reminder

The system reminds operators to perform lubrication, cleaning, calibration, and other maintenance tasks according to preset cycles.

Maintenance Record Storage and Retrieval

All maintenance history is recorded, forming a complete equipment health file.

Automatic Mode

After preset formulas and parameters, the system can achieve fully automated operation from feeding, drying, metering, mixing to unloading, reducing reliance on manual labor.

Manual Mode

Suitable for equipment debugging, post-maintenance trial runs, or handling special working conditions, allowing operators to perform inching control on individual equipment.

Seamless Mode Switching

During automated production, if emergency intervention is needed, the system can be switched to manual mode at any time to ensure production continuity and safety.

Remote Operation via Computer

Engineers can monitor the entire production process and adjust parameters from their offices via LAN or the Internet.

Mobile App Monitoring

Managers can view output, equipment status, and fault information anytime, anywhere via a mobile app, achieving “factory on your phone” management.

Remote Fault Diagnosis and Program Updates

Technical personnel from equipment suppliers can remotely access the system for fault diagnosis, program repair, and optimization upgrades, providing efficient technical support.

Storage of Commonly Used Mixture Proportions Templates

Save mature formulas as templates for one-click recall during subsequent production, eliminating human input errors.

Storage of Project-Specific Parameters

Establish independent parameter sets for different engineering projects for convenient management.

Access Control Function

Set different levels of operation permissions (e.g., administrator, operator, observer) to prevent unauthorized personnel from modifying key parameters and ensure production safety.

Automatic Generation of Production Plans Based on Construction Progress

Integrating with the project management system, daily production task sheets are automatically generated based on the construction progress.

Finished Material Silo Full Warning and Production Rhythm Adjustment

The system intelligently adjusts the production rhythm based on material level gauge feedback and transport vehicle scheduling to avoid silo overflows or material shortages.

Multi-Equipment Collaborative Control

In large-scale mixing plants, multiple mixing stations can be coordinated for joint production, with unified resource scheduling to maximize overall efficiency.

Automatic Optimization of Burner Combustion Efficiency

The system calculates and optimizes the air-fuel ratio of the burner in real time based on parameters such as initial aggregate moisture content and target discharge temperature to ensure complete combustion and save fuel.

Variable Frequency Speed Control of Motors

High-power motors such as fans and water pumps are driven by variable frequency drives, adjusting speed according to actual needs to avoid over-powered motors and significantly reduce power consumption.

Intelligent reminder for no-load shutdown

When the equipment is in no-load operation for more than a set time, the system will actively remind the operator to shut down the equipment to reduce unnecessary energy consumption.

Small-scale mixing plant control systems

Typically possess basic mix proportioning and temperature control functions, meeting general and intermittent production needs.

Medium-scale mixing plant control systems

In addition to basic functions, they enhance data management and equipment protection capabilities, providing simple report statistics and fault logging, suitable for routine projects with certain quality requirements.

Large-scale intelligent mixing plant control systems

Integrate advanced functions such as remote control, intelligent optimization, and multi-device collaboration, possessing a comprehensive data analysis and decision support system, making them the first choice for large-scale key projects and high-standard construction.

Customized control systems

Specifically adapted for special working conditions such as high-altitude, extremely cold regions, or the production of special mixtures like rubber asphalt and warm-mix asphalt, with tailored control algorithms, thermal insulation and heating, and weather resistance.

Ingredient Mixing Accuracy Deviation

First, check if the weighing sensor is drifting and perform on-site calibration; second, verify if the mixing parameters have been incorrectly modified; finally, check for any jamming in the mechanical structure.

Unstable Temperature Control

Check if the temperature sensor (thermocouple/resistance level) is damaged or improperly installed; clean the burner nozzle and adjust the air-fuel ratio; check if the fuel line is clear.

Data Storage/Tracing Failure

Check if the hard drive or storage module is full or damaged; check if the software is the latest version, and restart the system or upgrade the software if necessary.

Remote Control Failure

First, check if the network connection is normal (network cable, switch); second, confirm that remote access permissions and firewall settings are correct; finally, check if the main control system is in a remote access allowed state.

In summary, modern asphalt mixing plant control systems have evolved from simple logic control into comprehensive management platforms integrating precision, efficiency, safety, and traceability. Their core value lies in continuously upgrading technology to fundamentally ensure consistent asphalt mixture quality, promote energy conservation and environmental protection in the construction process, maximize production efficiency, and ensure safe and reliable equipment operation. Therefore, when purchasing or upgrading an asphalt mixing plant, using the advanced nature, stability, and ease of use of its control system as core evaluation indicators is a strategic investment with a long-term vision that will undoubtedly bring substantial returns on your project quality and economic benefits.